Anti-slide pile of jointed arch structure

A technology of arch structure and anti-sliding piles, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as unclear force, difficult construction, and difficult to form holes, so as to reduce project investment, enhance anti-sliding effect, The effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

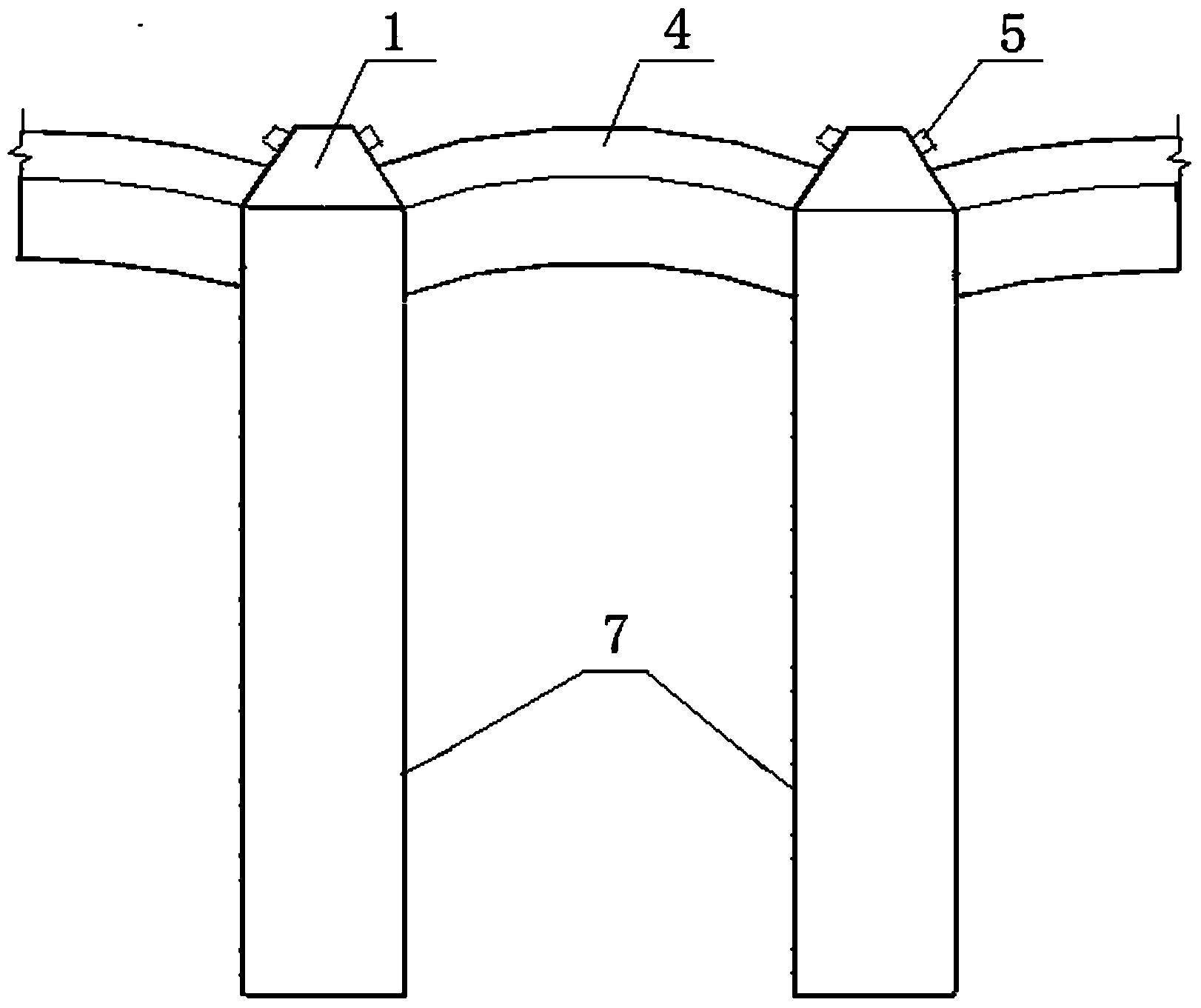

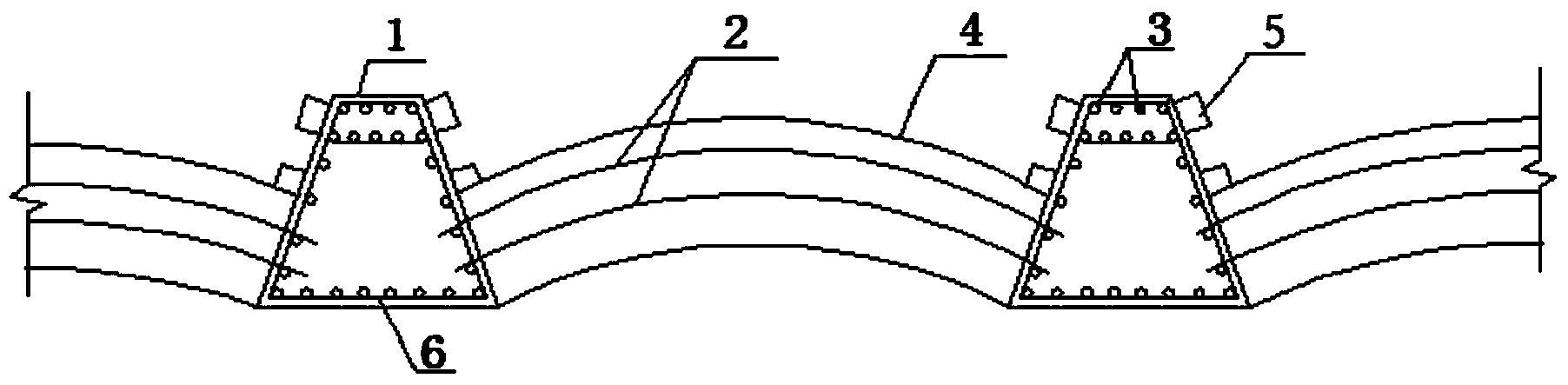

[0022] Embodiment 1: the present invention provides a kind of anti-sliding pile with arch structure, and its structure is as follows figure 1 , 2 As shown in . All are provided with the friction segment 7 that anti-slip tooth 5 forms; Described multiple reinforced concrete monolithic piles all take the side of longitudinal section of the short base of isosceles trapezoid as pile rear end to accept landslide thrust, pile rear end one The side is the compression area, the longitudinal section of the long base of the isosceles trapezoid is used as the front end of the pile, and the side of the front end of the pile is the tension area. The arch structure 4 is also a reinforced concrete structure, connected between two single piles , the arch structure 4 is connected to the tension zone of the isosceles trapezoidal single pile 1, and the landslide thrust between the single piles 1 is evenly transmitted to both sides of the isosceles trapezoid of the single pile through the arch s...

Embodiment 2

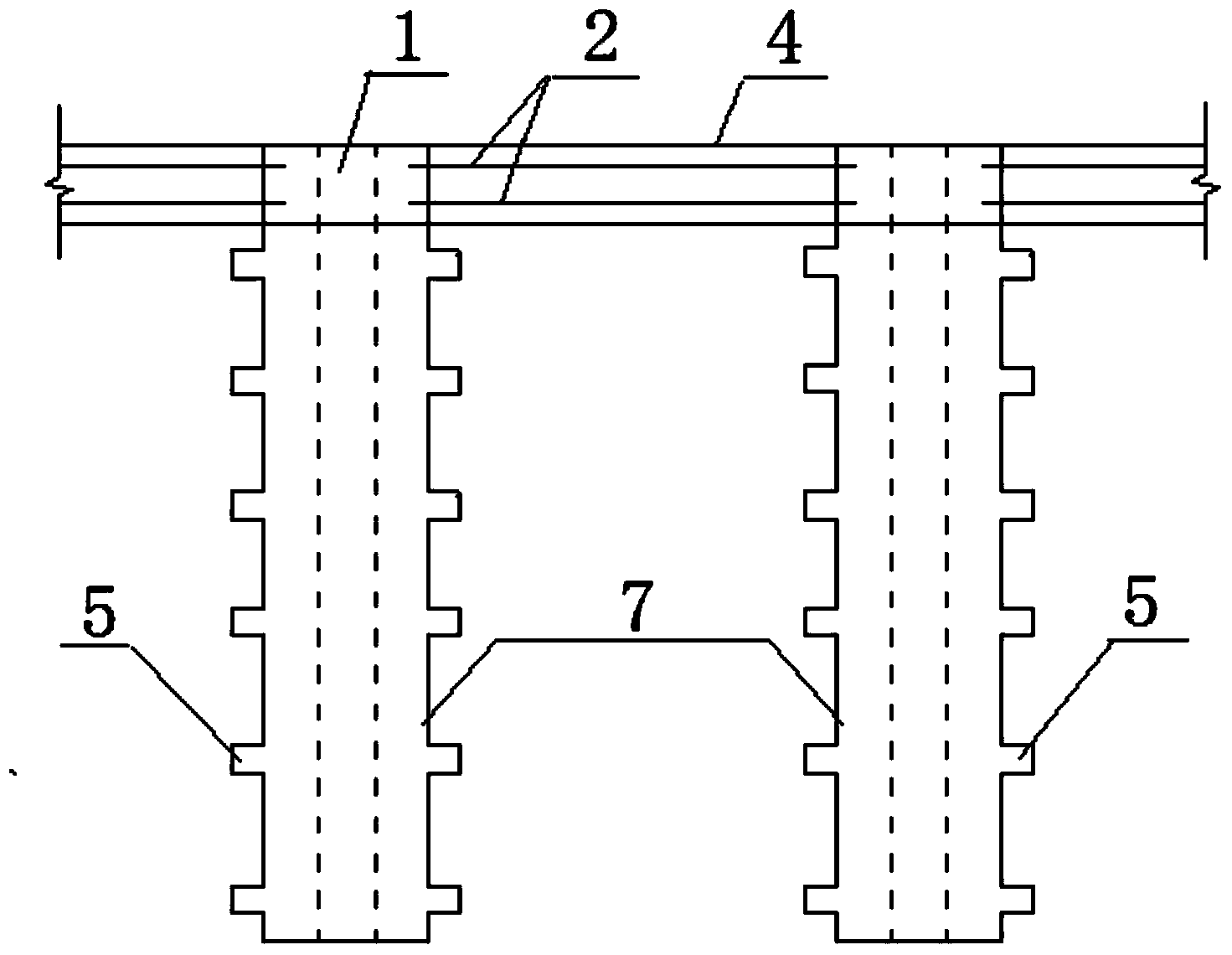

[0033]Embodiment 2: the present invention provides a kind of anti-sliding pile with arch structure, its structure is as Figure 4 As shown, it is composed of four reinforced concrete single piles 1 and an arch structure 4, and the two sides of the four single piles 1 are provided with semicircular anti-slip teeth 5 to form friction sections 7; other structures and construction Using method is the same as embodiment 1.

Embodiment 3

[0034] Embodiment 3: The present invention provides an anti-sliding pile with a combined arch structure, which is composed of 6 reinforced concrete single piles 1 and an arch structure 4, and the sides of the 6 single piles are provided with triangular cone-shaped anti-slip teeth The friction segment 7 that 5 forms; Others are all the same as embodiment 1.

[0035] The anti-sliding pile with reinforced concrete double-arch structure with pile side friction section of the present invention has the advantages of simple structure, strong operability of construction technology, safe and simple construction, etc. It can reduce costs when used for landslide control and has remarkable economic benefits. The combined arch anti-slide pile has broad application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com