Multi-bin cotton mixing machine

A multi-compartment cotton blending and cotton blending technology, which is applied in the direction of fiber mixing, textile and paper making, fiber treatment, etc., can solve the problems of unsatisfactory blending effect and achieve improved blending effect, good blending effect and smooth air flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

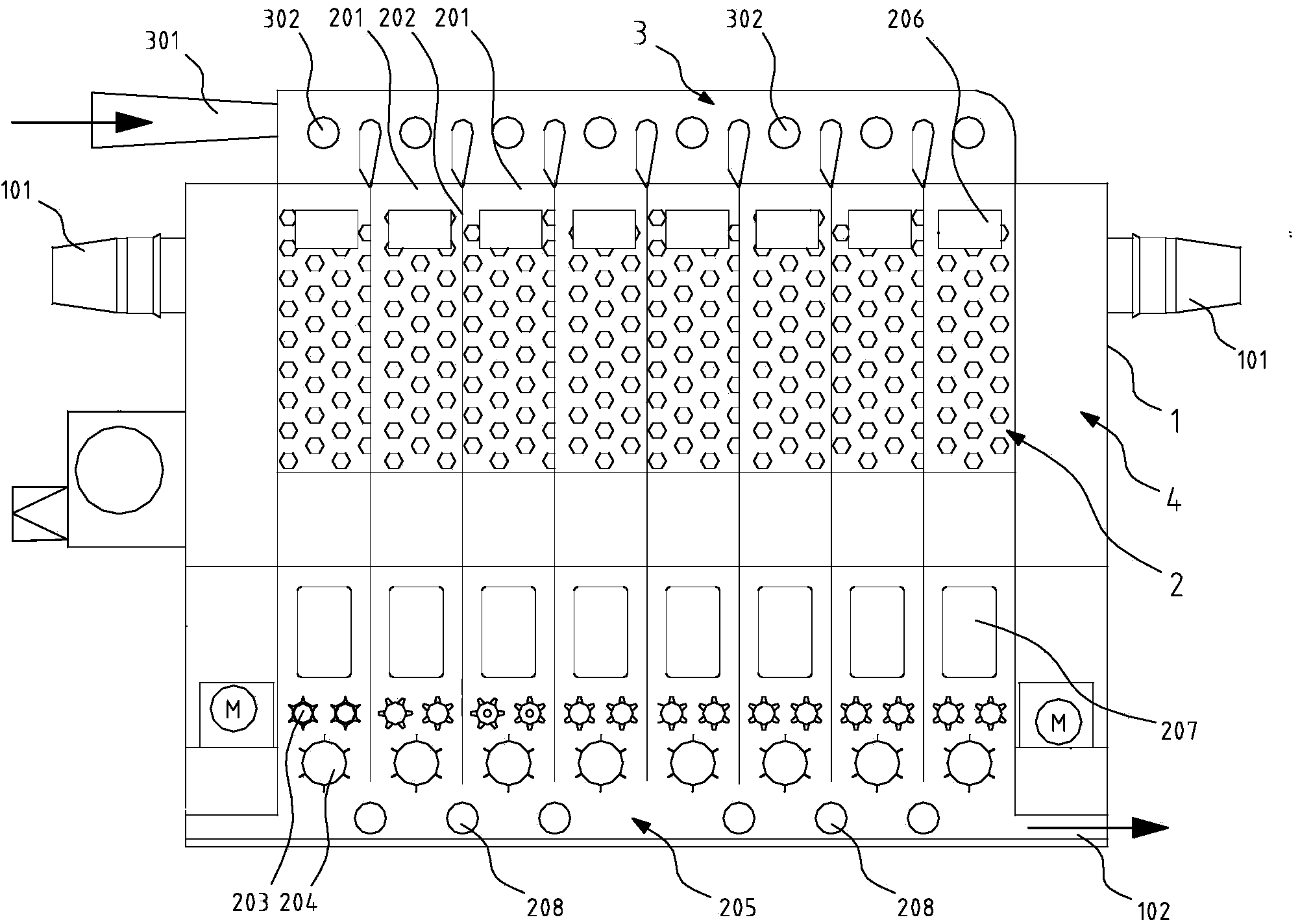

[0019] to combine figure 1 As shown, the multi-compartment blending machine includes a chassis 1 and a cotton storage compartment 2, the cotton storage compartment is placed inside the chassis, and the cotton storage compartment 2 adopts a multi-compartment structure such as a four-compartment, six-compartment, eight-compartment or ten-compartment structure. Cotton distribution channels 3 are arranged above the cotton storage bin 2, and the cotton distribution channels 3 communicate with the upper openings of each bin body 201 of the cotton storage bin 2 respectively, and an adjustable cotton distribution head is arranged at the upper opening of each bin body to use In order to adjust the amount of cotton entering the interior of the warehouse, so that the control of the amount of cotton in each warehouse is basically the same, a horizontal cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com