A reinforced plastic rod and its production device and method

A technology of reinforced plastics and production methods, applied in the field of composite materials, can solve the problems of low production efficiency, the variety of reinforced plastic rods cannot fully meet the requirements of technological progress, and poor bending performance of products, so as to avoid internal cracks and improve the quality of cross-linking and curing , Improve the effect of bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

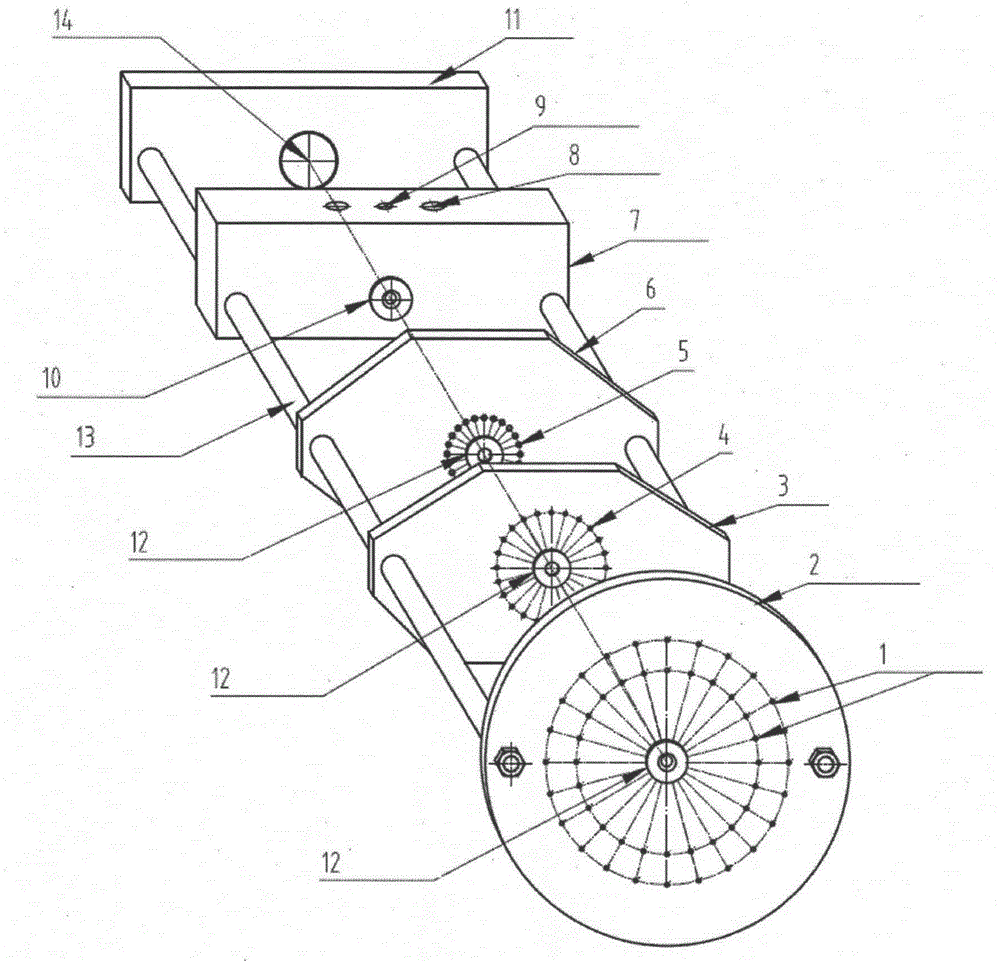

Method used

Image

Examples

Embodiment 1

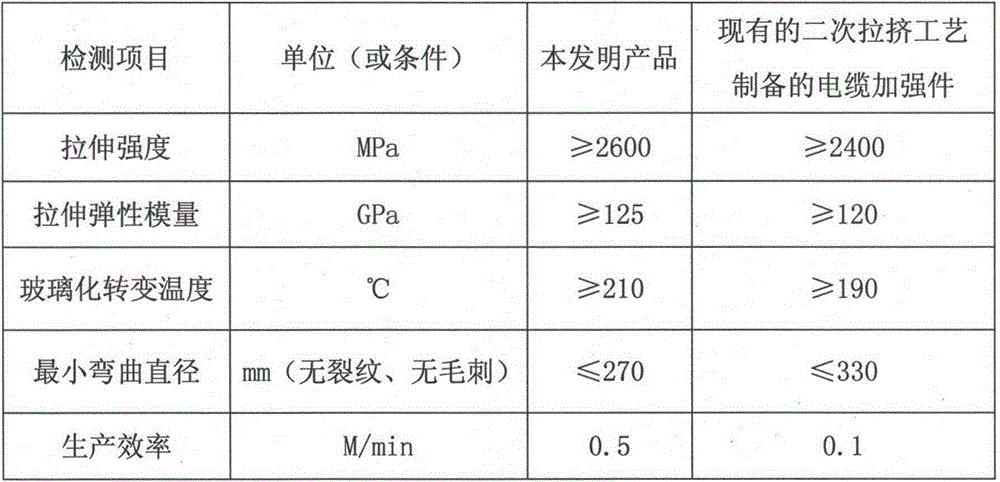

[0030] A reinforced plastic rod, the cross-section of which is a circle with a diameter of 6.0 mm, which is composed of 18 wt% of a thermosetting resin matrix and 82 wt% of reinforcing fiber yarns, the reinforcing fiber yarns are distributed in the thermosetting resin matrix, the There are two types of fiber yarns for reinforcement. The strength of the first fiber yarn is higher than that of the second fiber yarn, and the second fiber yarn is distributed around the first fiber yarn.

[0031]The first kind of fiber yarn described is the carbon fiber yarn of model 12K produced by Toray Corporation of Japan, and the second kind of fiber yarn is the glass fiber yarn of E-TM produced by Chongqing International Composite Materials Co., Ltd. The weight of the first fiber yarn accounts for 46wt% of the total weight of the reinforcing fiber yarn, and the weight of the second fiber yarn accounts for 54wt% of the total weight of the reinforcing fiber yarn. The raw material of the heat-cu...

Embodiment 2

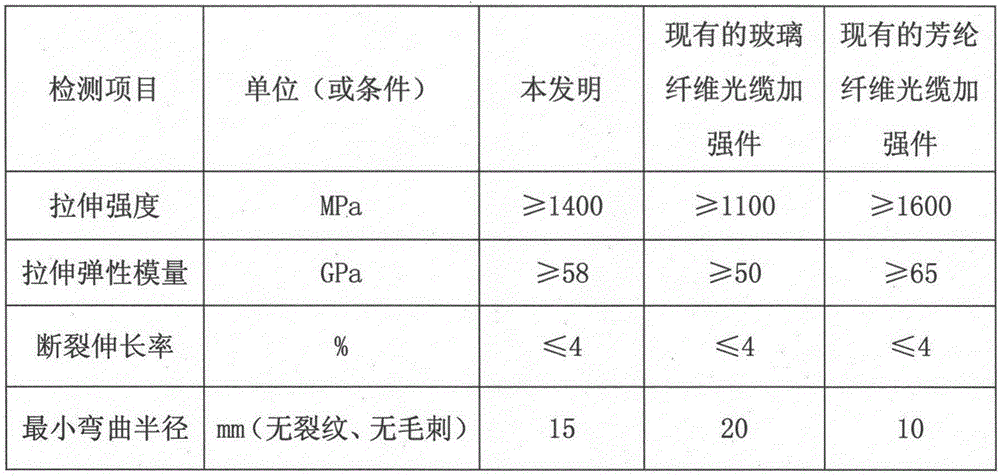

[0041] A reinforced plastic rod, the section of which is a circle with a diameter of 0.5 mm, which is composed of 28 wt% of a thermosetting resin matrix and 72 wt% of reinforcing fiber yarns, the reinforcing fiber yarns are distributed in the thermosetting resin matrix, the There are two types of reinforcing fiber yarns, the strength of the first fiber yarn is higher than that of the second fiber yarn, and the second fiber yarn is distributed around the first fiber yarn.

[0042] The first kind of fiber yarn described is the aramid fiber yarn of model 220DTex produced by DuPont Company, and the second kind of fiber yarn is the glass fiber yarn of E-TM model produced by Chongqing International Composite Materials Co., Ltd. The weight of one kind of fiber yarn accounts for 7wt% of the total weight of the reinforcing fiber yarn, and the weight of the second kind of fiber yarn accounts for 93wt% of the total weight of the reinforcing fiber yarn. The raw materials of the heat-curab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com