A kind of preparation method of nylon 6 nanofiber reinforced and toughened polyoxymethylene

A nanofiber, reinforcement and toughening technology, which is applied in the preparation field of nylon 6 nanofiber reinforcement and toughening polyoxymethylene, can solve the problem of unsatisfactory compatibility between resin and glass fiber, and achieve the effect of avoiding depolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

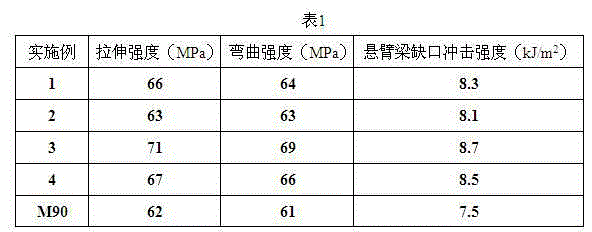

Examples

Embodiment 1

[0022] 1. Preparation of nylon 6 nanofibers by electrospinning

[0023] Prepare a nylon 6 formic acid solution with a concentration of 14%, place it in the spinning bath, adjust the electrode distance to 150mm, turn on the high voltage to 60kv, and collect nylon 6 nanofibers on the receiving substrate.

[0024] 2. Preparation of nylon 6 nanofiber reinforced and toughened polyoxymethylene

[0025] Mix 8 parts of nylon 6 nanofibers with 92 parts of polyoxymethylene evenly, put them into a twin-screw extruder, and melt and granulate.

[0026] The processing technology is as follows: twin-screw extruder, the temperature in the first zone is 160-170°C, the temperature in the second zone is 165-175°C, the temperature in the third zone is 170-180°C, the temperature in the fourth zone is 175-185°C, the head is 180-195°C, the screw speed 250-350rpm, residence time 3-5min, pressure 12-18MPa.

Embodiment 2

[0028] With embodiment 1, difference is:

[0029] Step (1) The concentration of nylon 6 formic acid solution is 12%.

Embodiment 3

[0031] With embodiment 1, difference is:

[0032] In step (2), 15 parts of nylon 6 nanofibers and 85 parts of polyoxymethylene are melted and granulated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap