Highly-reliable fast locking mechanism

A locking mechanism and reliable technology, applied in the directions of transportation and packaging, vehicle parts, etc., can solve problems such as hidden safety hazards, poor natural environment protection ability, inconvenience, etc., to ensure locking and unlocking, reliable locking and unlocking, convenient and convenient. Effects of operations and inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

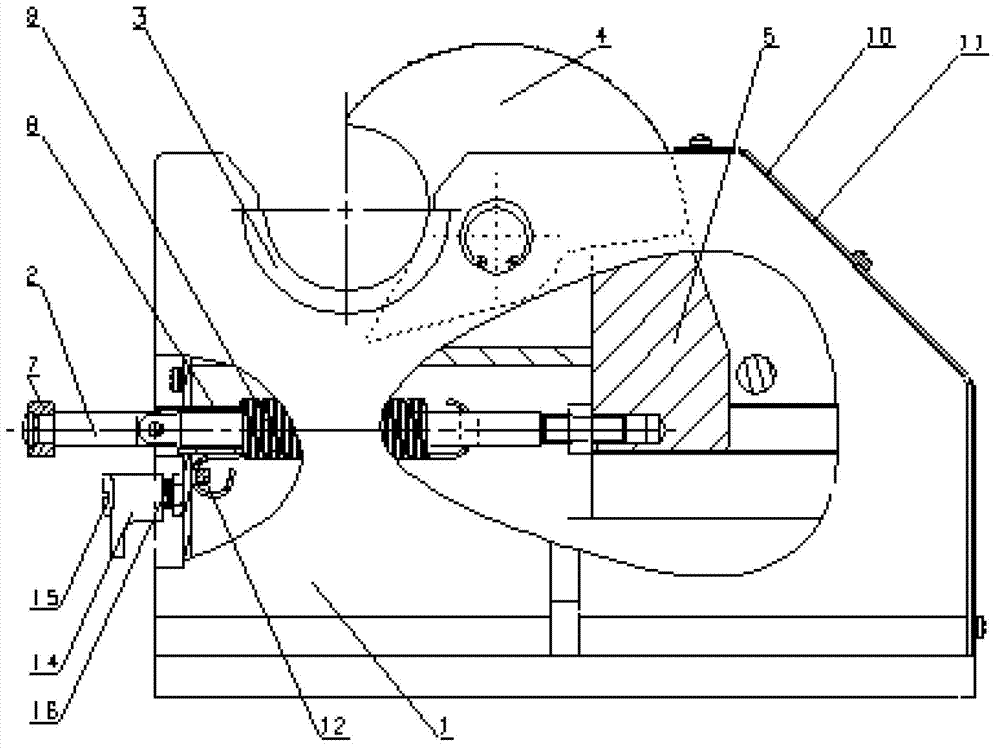

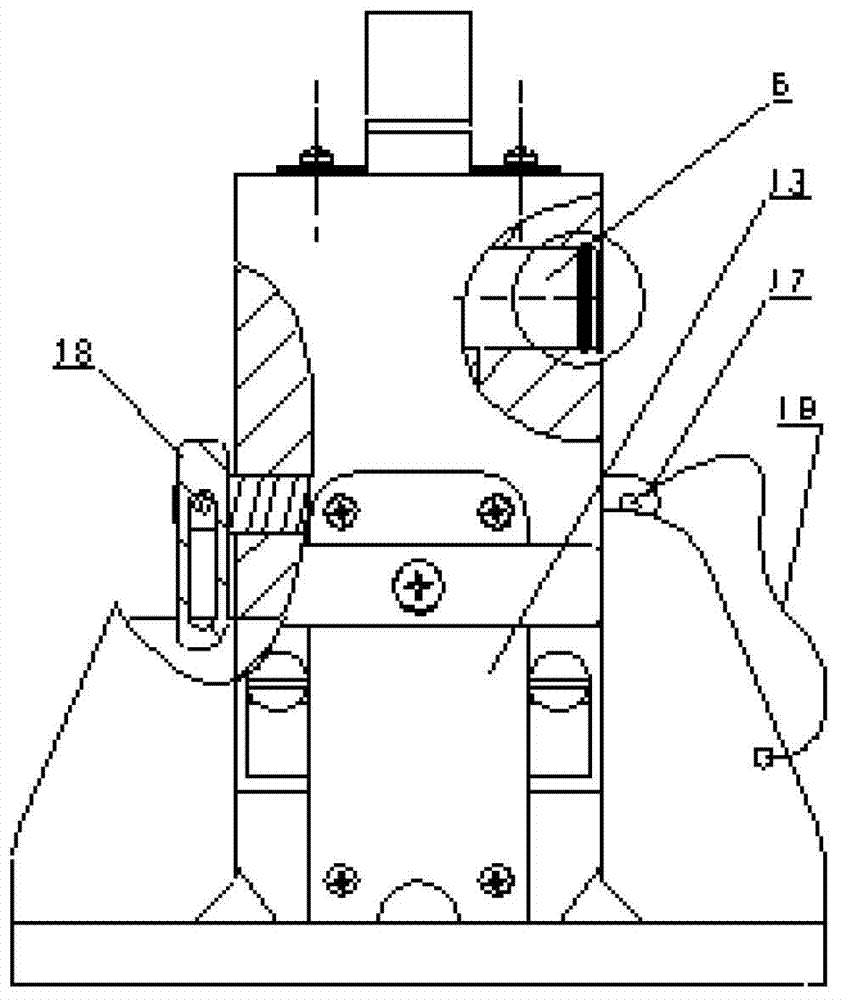

[0027] Such as figure 1 , figure 2 As shown, the highly reliable fast locking mechanism of the present invention includes a base 1, a push-pull rod 2, a copper sleeve 3, a lock plate 4, a lock block 5, a pin shaft 6, a handle 7, a sleeve 8, a return spring 9, a rubber Pad 10, dust cover 11, positioning strip 12, sealing plate 13, block 14, fixing bolt 15, spring 16, stop pin 17, stop piece 18, wire rope 19;

[0028] The lower part on the left side of the base 1 is a cavity, and the upper part is a semicircular hole. There are connecting holes for fixing bolts 15 and connecting holes for the sealing plate 13 at the end of the cavity, and there are pin shaft 6 mounting holes beside the semicircular hole; Cavity, the lower part is a slideway, there are stop pin 17 connection holes above the slideway, and there are 11 connection holes for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com