Ink-jet recording device

An inkjet recording and loading technology, applied to printing devices, printing, etc., can solve problems such as paper jams, sheet lifting, nozzle pressing sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

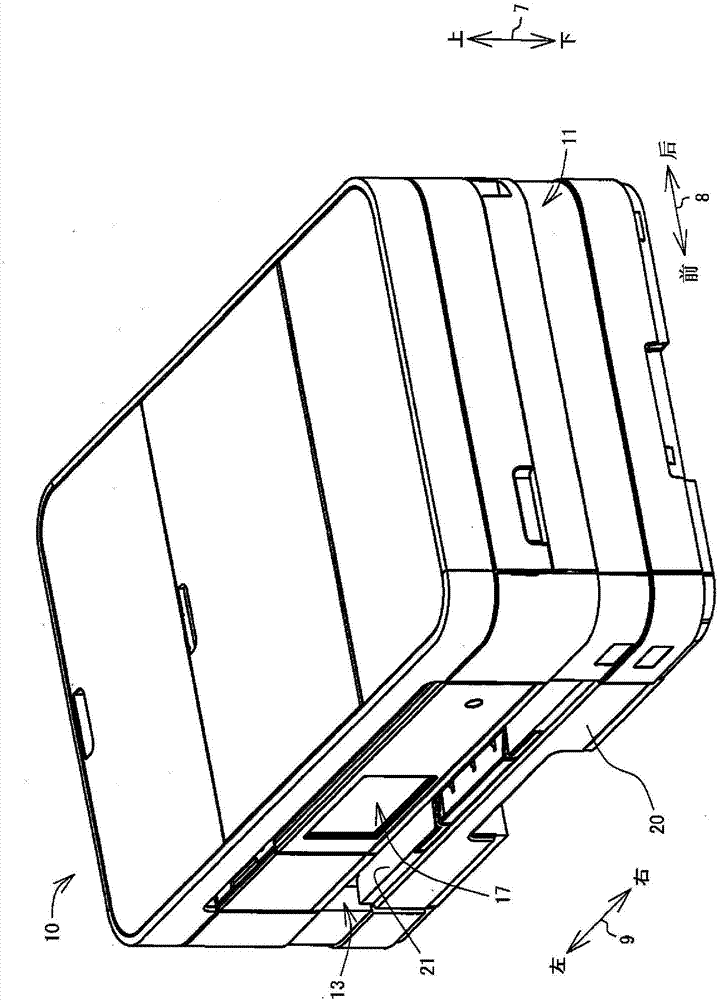

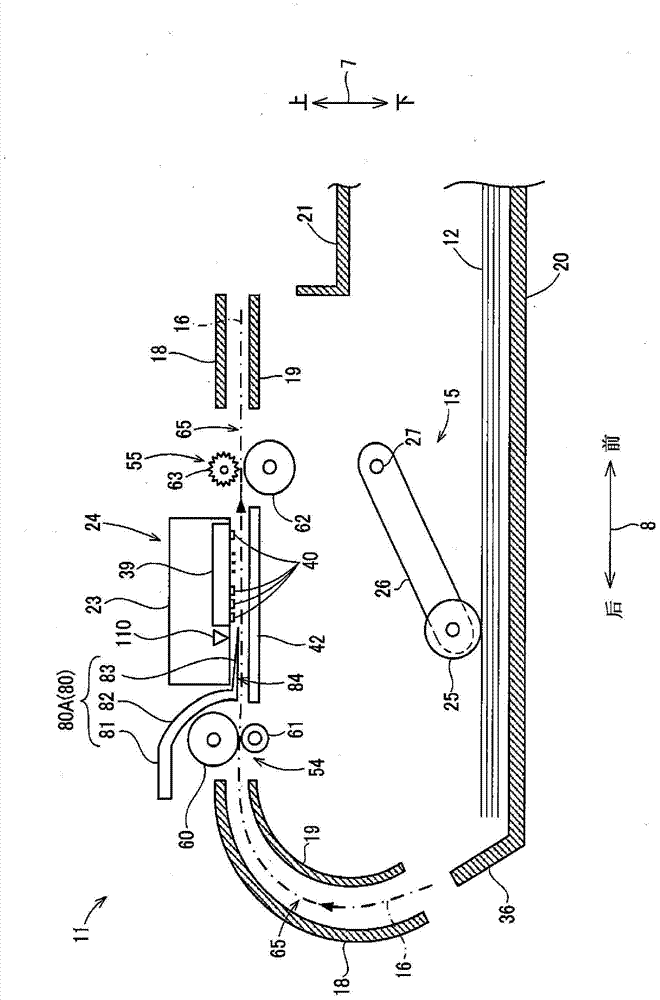

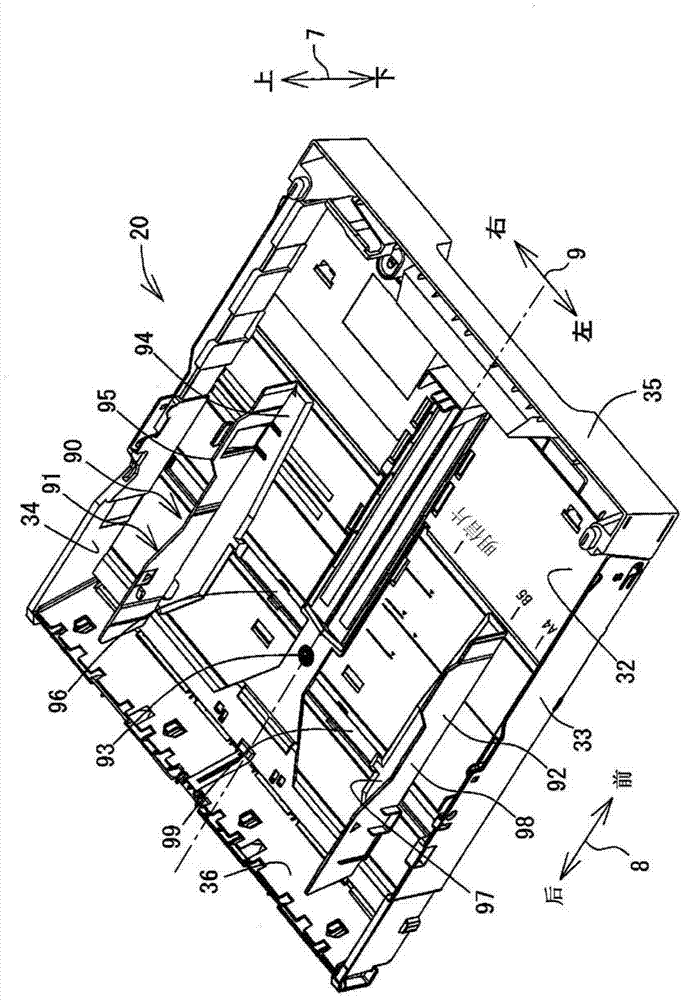

[0037] Embodiments of the present invention will be described below. In addition, embodiment described below is just an example of this invention, It goes without saying that the embodiment of this invention can be changed suitably within the range which does not change the summary of this invention. In addition, in the following description, the multifunction peripheral 10 is set to a usable state ( figure 1 state) defines the up and down direction 7 as the datum. Furthermore, the front-rear direction 8 is defined with the side of the multifunction peripheral 10 on which the opening 13 is provided as the near side (front). Furthermore, the left-right direction 9 is defined by viewing the multifunction peripheral 10 from the near side (front).

[0038] [Whole Structure of Compound Machine 10]

[0039] Such as figure 1 As shown, the multifunction peripheral 10 is formed in a substantially rectangular parallelepiped. In the lower part of the multifunction machine 10, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com