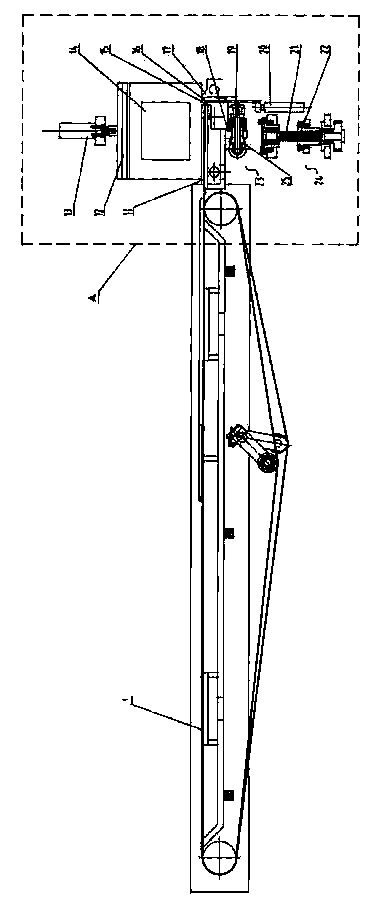

Face paper conveying mechanism for packaging box face wrapping machine

A technology of conveying mechanism and cladding machine, which is applied in packaging, transportation and packaging, paper/cardboard containers, etc., and can solve problems such as high labor costs, production efficiency, poor cladding effect, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

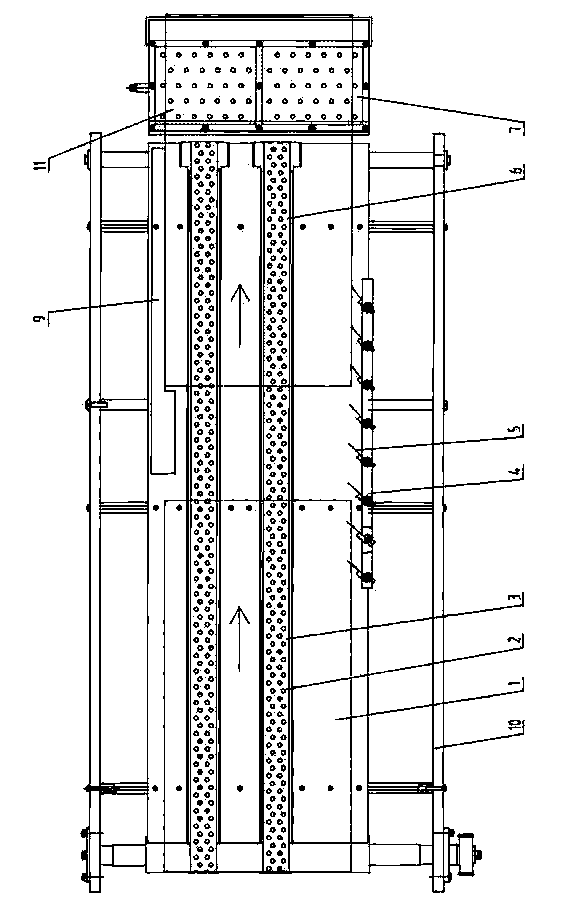

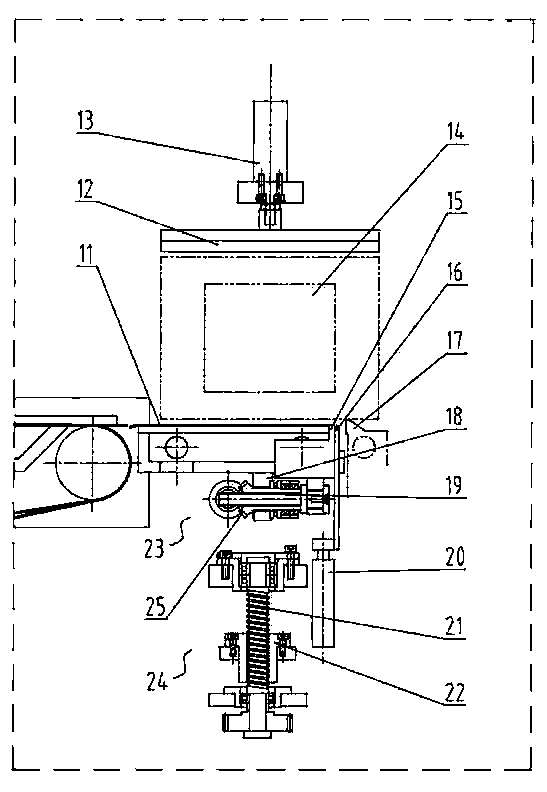

[0018] The tissue conveying mechanism of this kind of packaging box covering machine includes a frame 10, a conveying platform 1 and a front gauge platform 11. Pressure belt 2, the negative pressure belt 2 is a conveyor belt with an air source, which absorbs the facial tissue on the conveyor belt to ensure smooth transportation of the facial tissue and prevents the facial tissue from detaching from the conveyor belt. The negative pressure belt 2 is divided into The first wind zone 3 and the second wind zone 6, the front gauge platform 11 has a suction zone 7, and in the working condition, the second wind zone 6 and the suction zone 7 alternate suction operations, the front gauge The front of the platform 11 is provided with a front regulation 17, and the front regulation platform 11 is installed on the lifting device 24, and the lifting device 24 includes a motor, a lifting screw 21 and a nut 22 matched with the lifting screw, and the lifting screw 21 is connected with motor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com