Swing type slicing and feeding device at variable speeds

A feeding device and slicing technology, applied in metal processing and other directions, can solve the problems of different thickness of slices and difficulty in ensuring hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

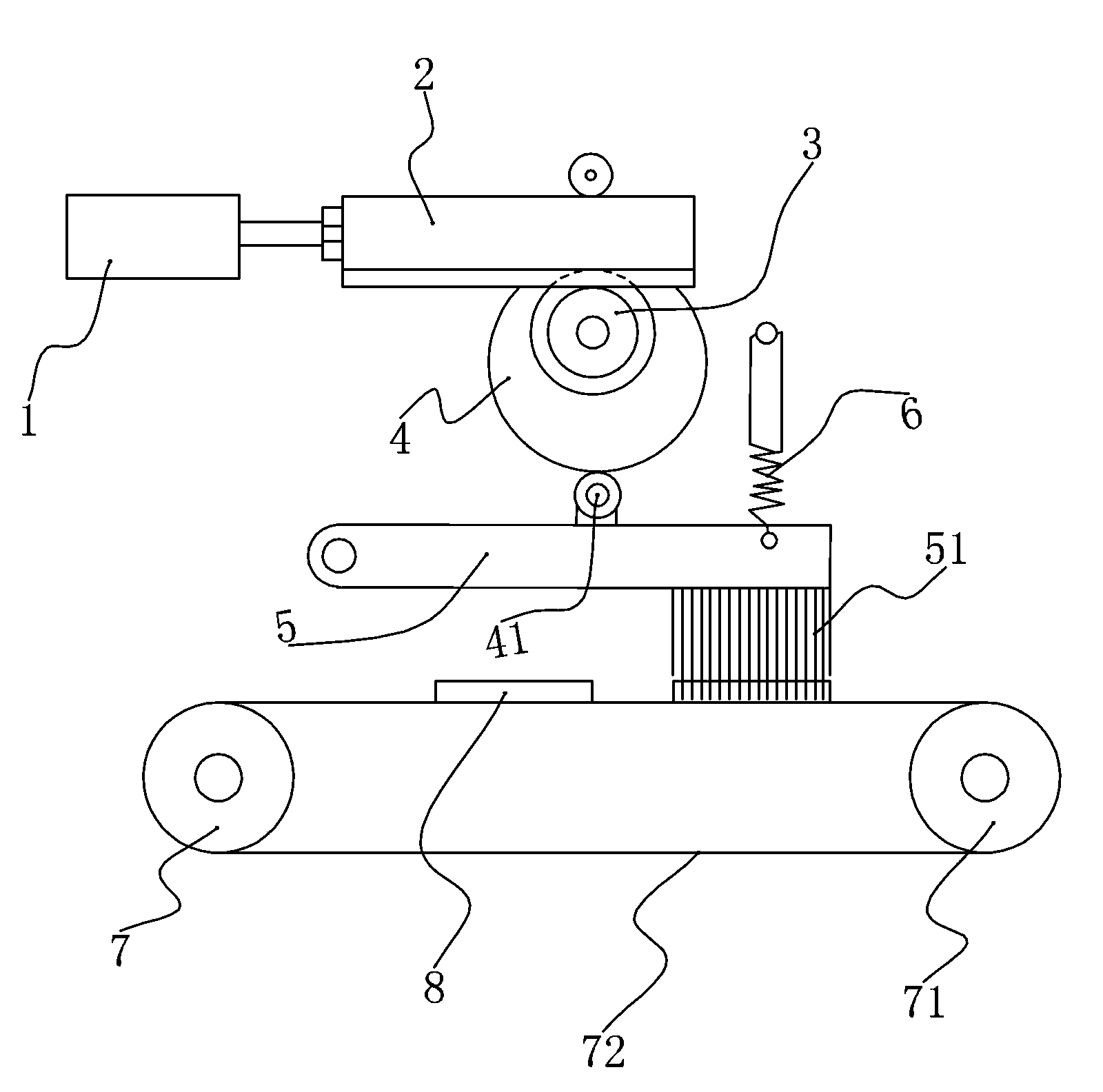

[0009] Such as figure 1 As shown, the variable speed oscillating slice feeding device of the present invention includes a bracket on which a cylinder 1 is fixed, the piston rod of the cylinder 1 is fixedly connected to the rack 2, the tooth surface of the rack 2 faces downward, and a gear is meshed 3. The gear 3 is coaxially connected to a cam 4, the flange of the cam 4 is connected to the middle part of the knife bar 5 through a cam follower 41, one end of the knife bar 5 is hinged on the bracket, and the knife bar 5 The other end is provided with cutter head 51, and cutter head 51 is provided with several parallel blades; A drive pulley 7 is hinged on the support, and a driven pulley 71 is also hinged on the support, drive pulley 7 and The driven pulley 71 is connected by a belt 72 . In addition, a coil spring 6 is connected to the free end of the knife rod 5, and the other end of the coil spring 6 is fixed on the bracket. Adding the coil spring 6 can speed up the return o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com