Method for preventing cracks of runner blade of mixed-flow water turbine

A technology for runner blades and water turbines, which is used in the analysis of solids, testing metals, and material inspection products using sonic/ultrasonic/infrasonic waves, and can solve problems such as blade cracks, runner blade inspection requirements are too loose, and blade quality requirements cannot be guaranteed. , to achieve the effect of reliable operation and reasonable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

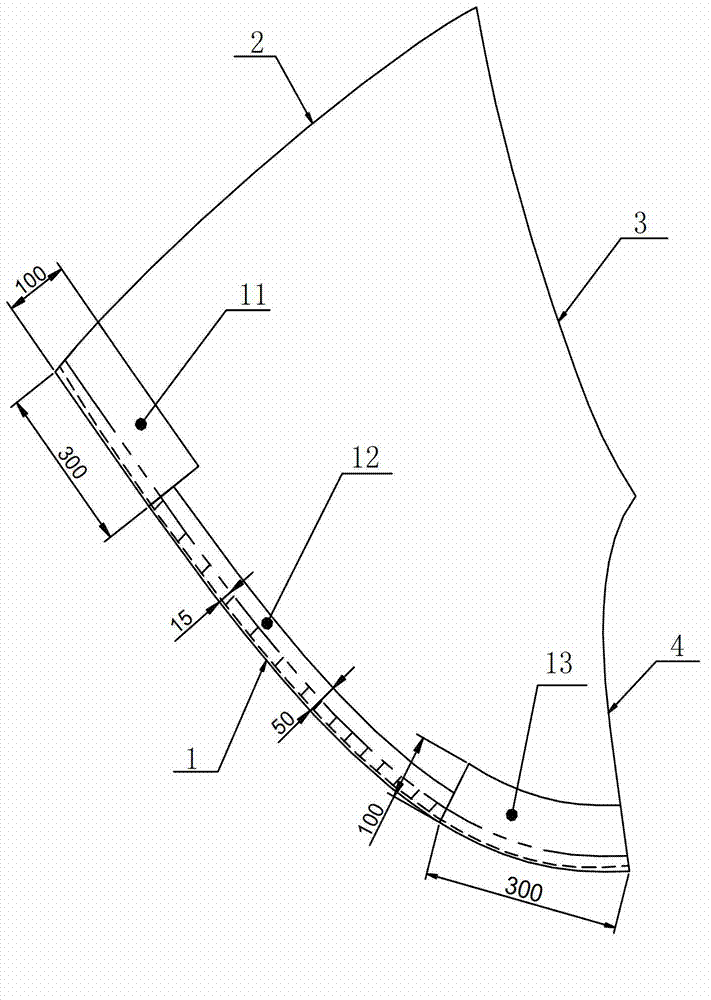

[0018] The runner blades of the Francis turbine are assembled between the upper crown and the lower ring of the runner. The shape of the runner blades is as follows: figure 1 As shown, it is surrounded by four curved sides, which are the water outlet side 1, the upper crown connection side 2, the water inlet side 3 and the lower ring connection side 4, and the runner blade will be connected to the upper crown through the upper crown connection side 2 , connect edge 4 to the lower ring via the lower ring.

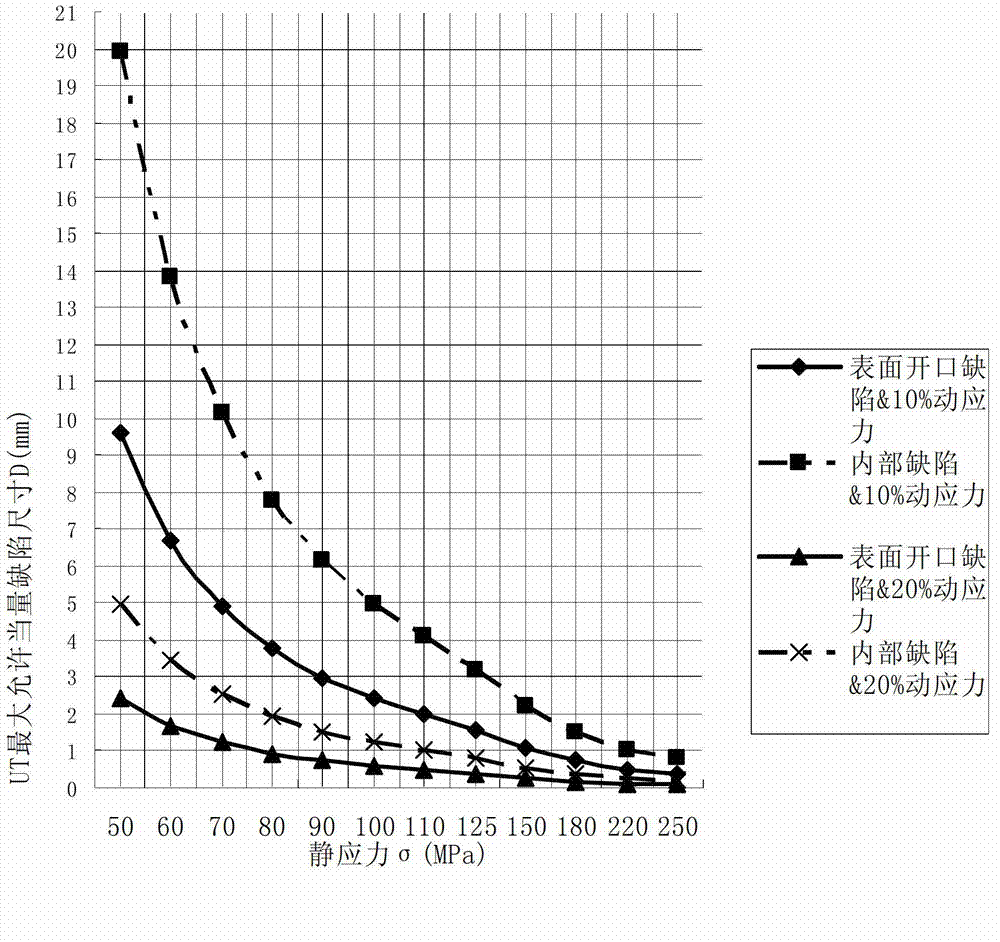

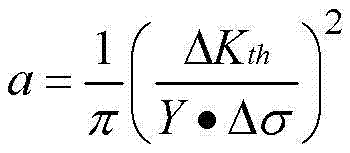

[0019] Practice has proved that cracks are most likely to occur near the water outlet during the operation of the runner blades. Therefore, the water edge of the runner blade needs to be used as a key area for quality assurance. According to different stress levels, the present invention further divides the water outlet edge of the runner blade into several different areas, and performs quality control according to different standards.

[0020] Therefore, the first problem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com