Flux for busbars of lead-acid batteries

A lead-acid battery and busbar technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of poor melting of plate lugs and lead liquid, and many bubbles, and reduce the time of casting and welding batteries. The effect of lead slag reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below.

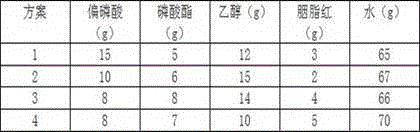

[0022] In view of the above effects, it can be properly adjusted within the formula range according to the welding quality: the welding between the lug and the lead liquid is not thorough enough, and the metaphosphoric acid can be adjusted to the upper limit (plan 1). If the surface of the lug is oxidized, it is beneficial to use more metaphosphoric acid. Cast welding; if there are bubbles in the welding part, the ethanol can be adjusted to the upper limit (Scheme 2). If the welding is easy to explode lead or produce pores, the solution with more ethanol is good for casting welding; if the lead liquid does not stick to the plate lug, the phosphate ester can be adjusted The upper limit (Scheme 3), if the lugs are not sticky to lead liquid, the solution can be improved by using more phosphate esters; if there is flux absorbed on the separator paper or the plate, carmine can be adjusted to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com