Tritium labeling reaction device

A reaction device and marking technology, applied in chemical instruments and methods, chemical/physical processes, methods of chemically changing substances by using atmospheric pressure, etc. Open and other problems to achieve the effect of shortening the vacuuming time of the system, maintaining high vacuum for a long time, and reducing the number of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

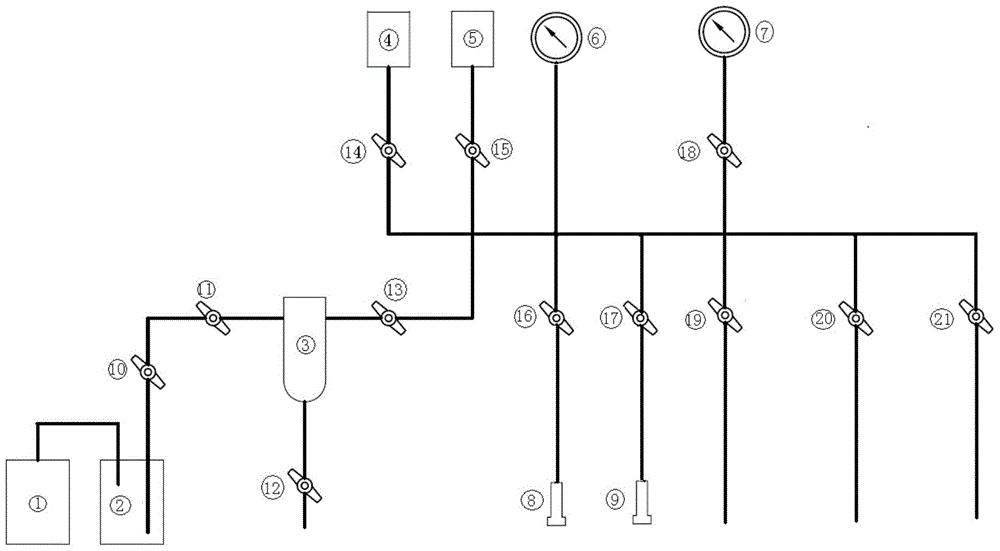

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] The device of the invention is composed of 316 stainless steel pipes, bellows valves, four-way pipes, three-way ball valves, vacuum gauges, pressure gauges and other components, and is used for the release of tritium gas, tritium labeling reaction and recovery of tritium gas. The body material of the bellows valve is 316 stainless steel, the pressure resistance is above 30 atmospheres, and the leakage rate of the valve is less than 4×10 -9 ml / s, the switch design life of the valve exceeds tens of thousands of times, and the operating temperature range is -23 to 148°C. The pipeline is internally polished 316 stainless steel tube, which is convenient for cleaning before installation and avoids the adsorption of impurity gas on the inner wall. The cold trap and buffer bottle are all made of 316 stainless steel. Valves and stainless steel pipes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com