Dynamic gas distribution system for simulating tail gas of ship

A ship exhaust and dynamic gas distribution technology, which is applied in the direction of gas and gas/steam mixing, fluid mixer, mixer accessories, etc., can solve the problem of inability to provide large flow continuously for a long time, poor anti-corrosion performance of equipment, and insufficient pertinence and other problems, to achieve the effect of flexibility, good air tightness and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

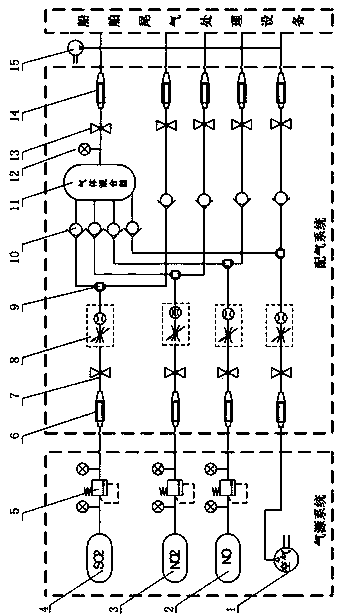

[0031] Such as figure 1 As shown, the dynamic gas distribution system for simulating ship exhaust provided by the present invention includes a gas source system and a gas distribution system.

[0032] The gas source system includes high-pressure gas cylinders, air compressor 1, pressure reducing valve 5, pressure gauge 12 and gas pipelines. Air compressor 1 is a Y2K-1 model produced by Fujian Juba Machinery Co., Ltd. The high-pressure gas cylinder provides high-pressure pure gas and 99.9% purity gas provided by Shanghai Maxtor Special Gas Co., Ltd.

[0033] The gas distribution system includes an inlet port 6, an inlet ball valve 7, a flow meter 8, a three-way ferrule joint 9, a one-way valve 10, a gas mixer 11, an outlet ball valve 13, an outlet port 14, a pressure gauge 12 and a gas pipeline. Both the inlet interface and the outlet interface incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com