Slider for slide fastener

A technology for sliders and zippers, applied in the field of sliders for zippers, can solve the problems of small size and reduced necessary strength of sliders, and achieve the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

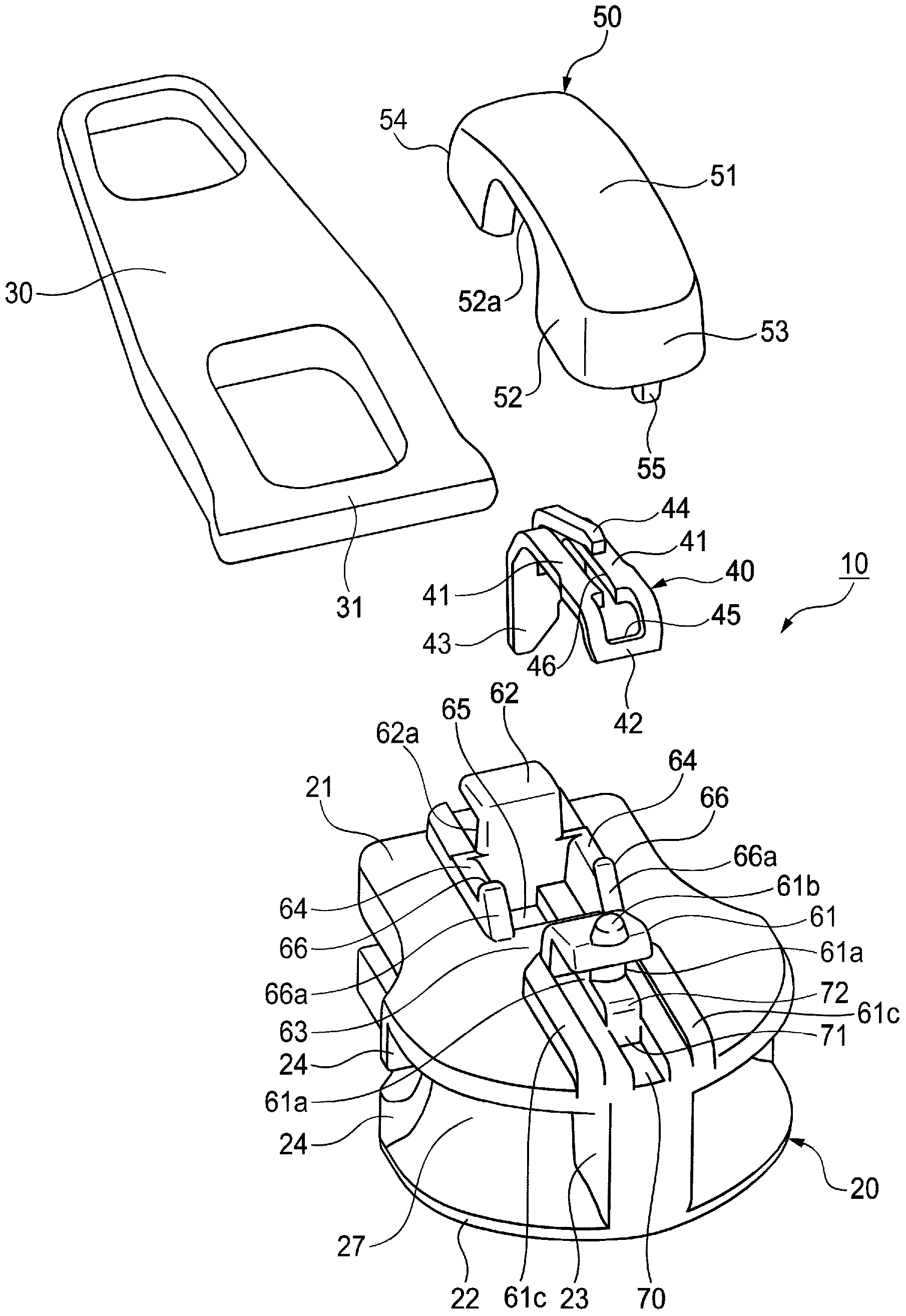

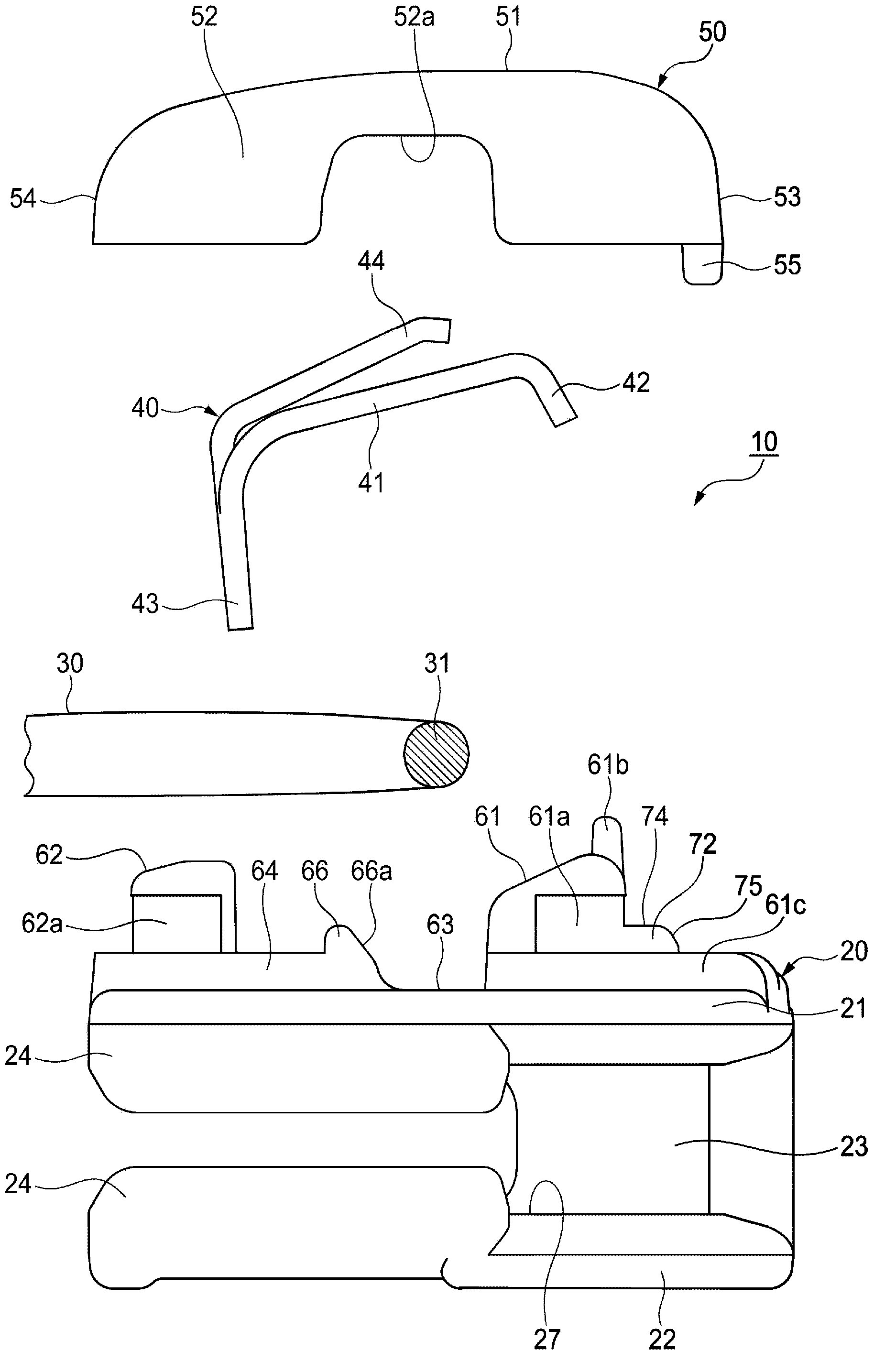

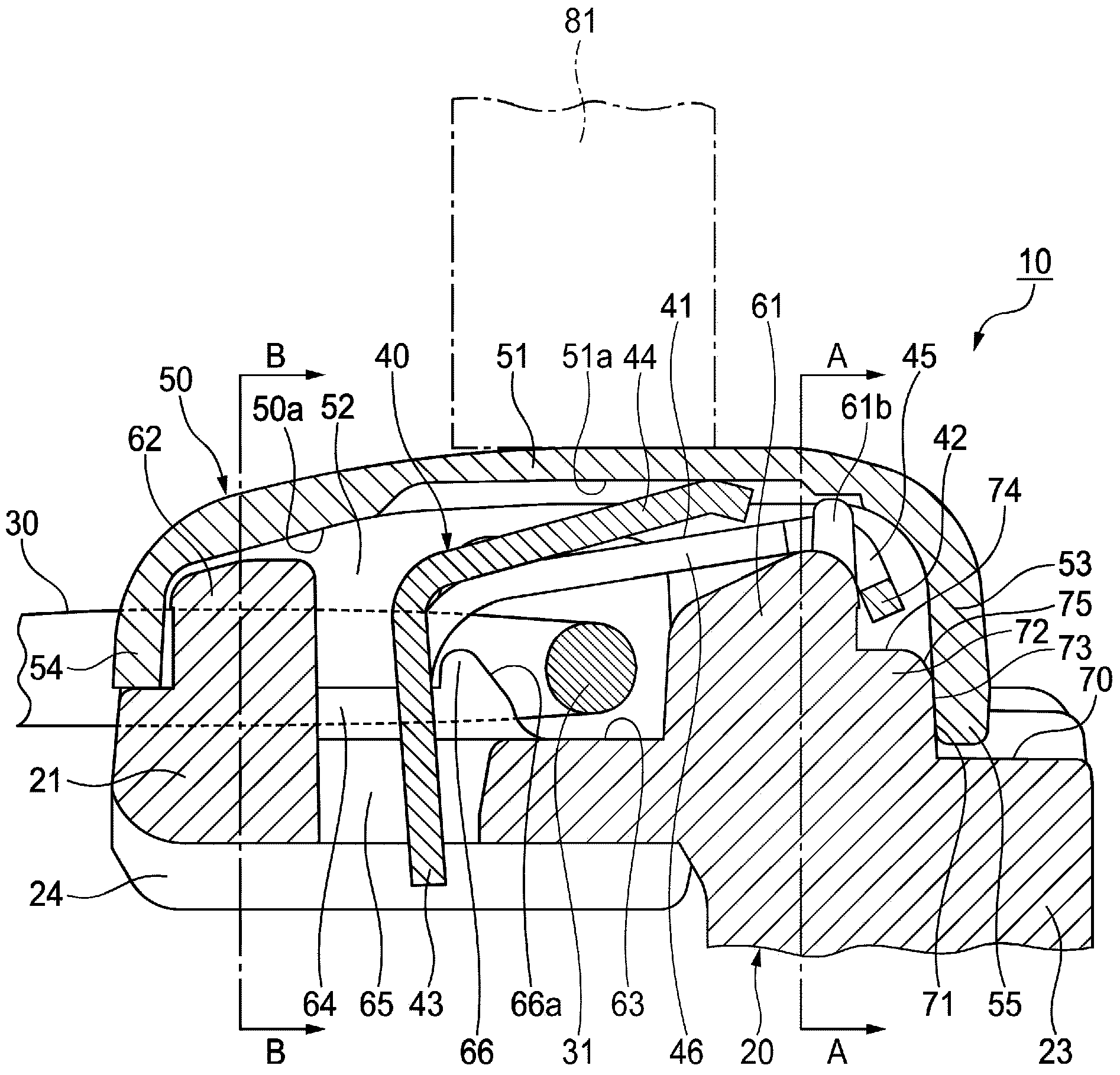

[0022] Hereinafter, one Embodiment of the slider for slide fasteners which concerns on this invention is demonstrated in detail based on drawing. In addition, in the description mentioned later, let the side which is the side where the slider width is wide and the fastener elements come out separated as a shoulder opening side, and let the side which is the side where the slider width is narrow and the fastener elements come out meshed be the shoulder opening side. Posterior side. In addition, the shoulder side is defined as the front, the rear mouth side is defined as the rear, the sliding direction of the slider is defined as the front-rear direction, and the direction perpendicular to the front-rear direction and parallel to the fastener tape (not shown) is defined as the left-right direction (width direction). The direction perpendicular to the front-rear direction and the left-right direction is the up-down direction.

[0023] Such as Figure 1 ~ Figure 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com