Magnetic group flaw detection method and device for blind rivets

A flaw detection device and technology of pulling rivets, which are applied in the direction of material magnetic variables, etc., can solve the problems of high excitation power, easy burns of workpieces, and failure to meet the needs of rivet flaw detection, etc., to achieve the effect of ensuring sensitivity and low excitation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The method for detecting the magnetic grouping of rivet groups in this embodiment includes the following steps:

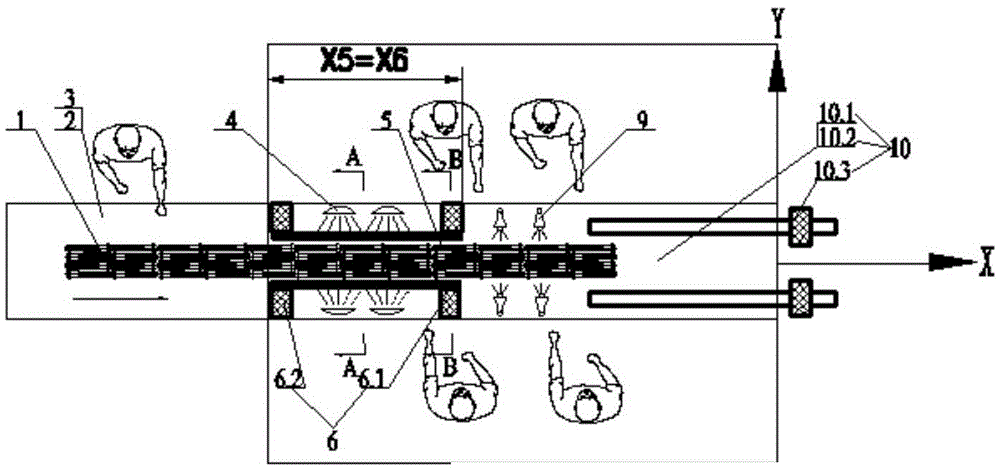

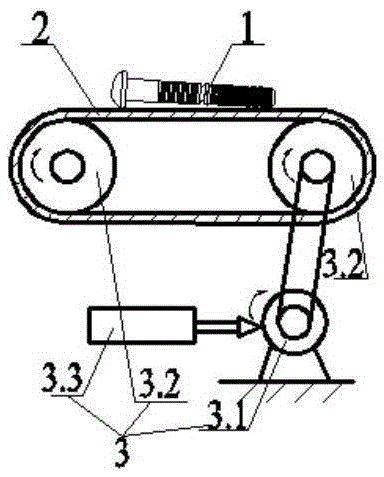

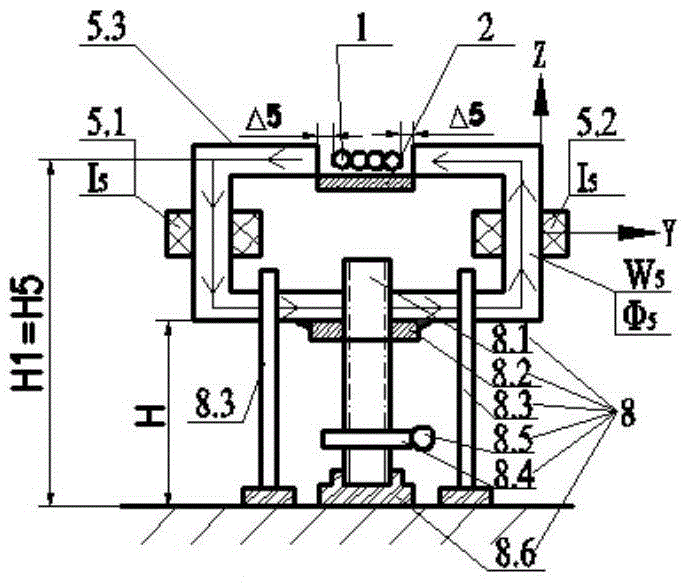

[0020] 1) Add the following process equipment: ①See figure 1 , Set up a stainless steel chain 2 and a stepping conveying mechanism 3 for conveying multiple rivets 1. ①See image 3 , Setting includes opening yoke 5.3, pulling rivet 1, gap Δ 5 Broadband closed circumferential magnetic circuit W formed 5 And the two series-connected circumferential excitation coils 5.1 and 5.2 set on the opening yoke, and the two series-connected axial excitation coils 6.1, 6.2 set on the outer periphery of the rivet, see Figure 7 , There is a thyristor converter circuit 7.1 in the magnetizing power supply 7 and outputs two controllable alternating currents with a phase difference of 120° 5 , Ι 6 They are provided to two sets of excitation coils in the circumferential and axial directions respectively, thereby generating a composite magnetic field Φ. ③See you image 3 , Provide a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com