Machine vision technology-based surface mounted device PIN smoothness detection equipment

A technology of machine vision and detection equipment, applied in instruments, measuring devices, optical devices, etc., to achieve the effect of automatic deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

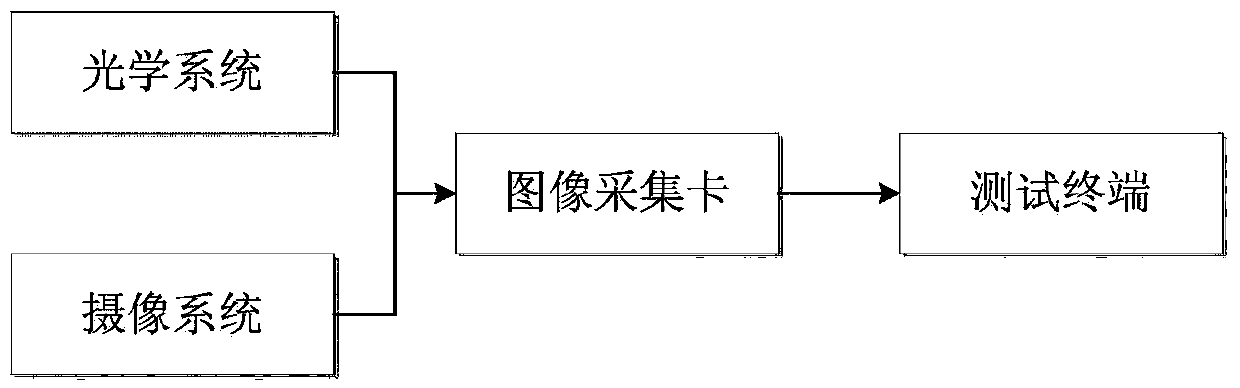

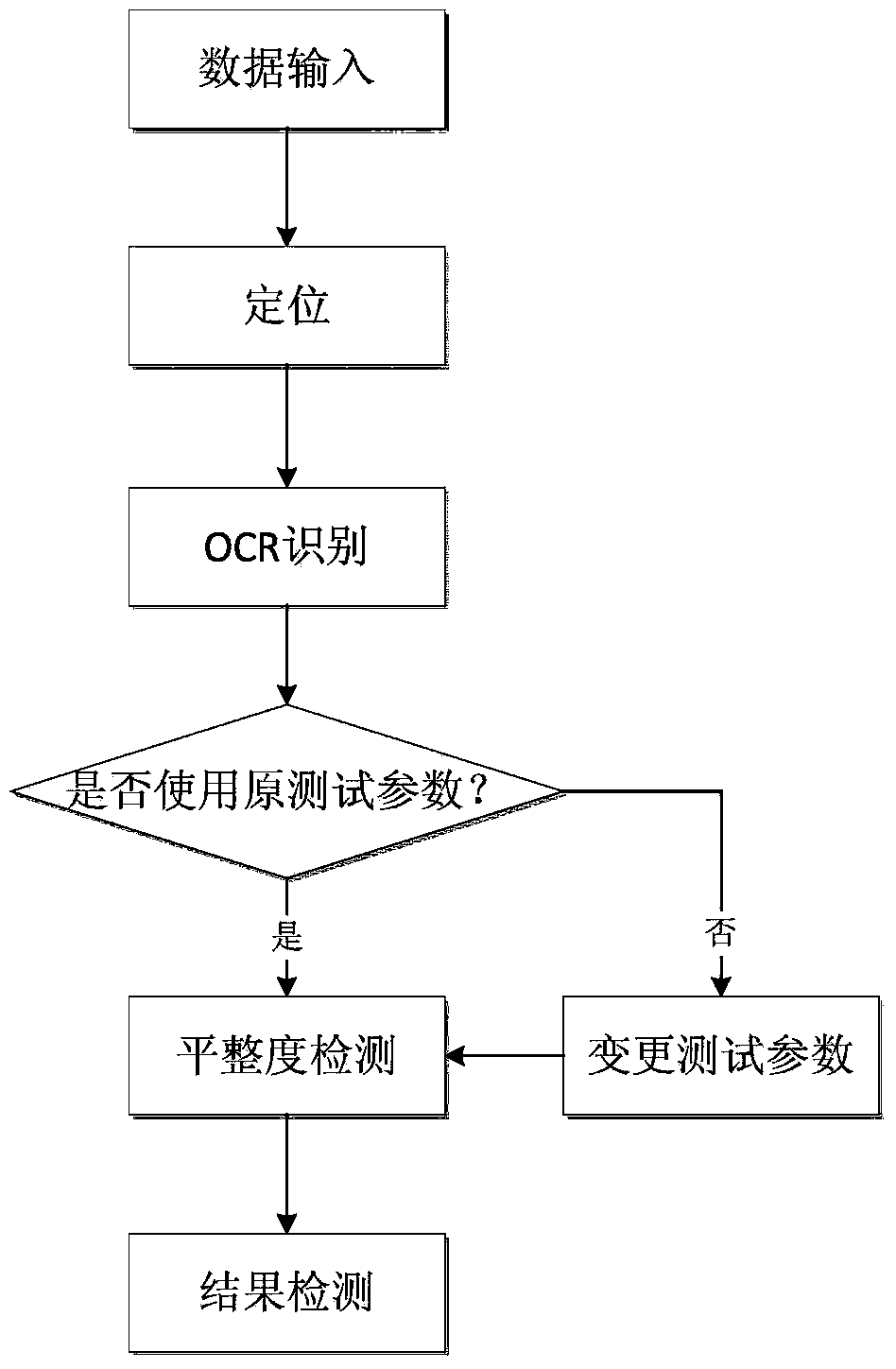

[0019] The following is attached figure 1 The connection between the various parts of the present invention is described in further detail:

[0020] A PIN pin flatness detection device based on machine vision technology, including four parts: an optical system, a camera system, an image acquisition card and a test terminal; the above optical system and the above camera system work together to complete the image acquisition of the sample to be tested Work, the above-mentioned camera system transmits the original image data to the above-mentioned image acquisition card, and the above-mentioned image acquisition card processes the original image data into digital image data and then transmits these data to the above-mentioned test terminal, and finally processes the digital image data by the above-mentioned test terminal And output the corresponding test results after screening.

[0021] The optical system is composed of high-brightness LED light sources.

[0022] The camera sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com