Pyrolysis-gas-recyclable medical waste pyrolysis treatment device

A treatment device and technology for medical waste, which is applied in the field of small-scale high-efficiency medical waste pyrolysis treatment devices, can solve problems such as secondary pollution, high cost of centralized medical waste treatment, tar clogged pipelines, etc., to save electricity and improve heat utilization Efficiency, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

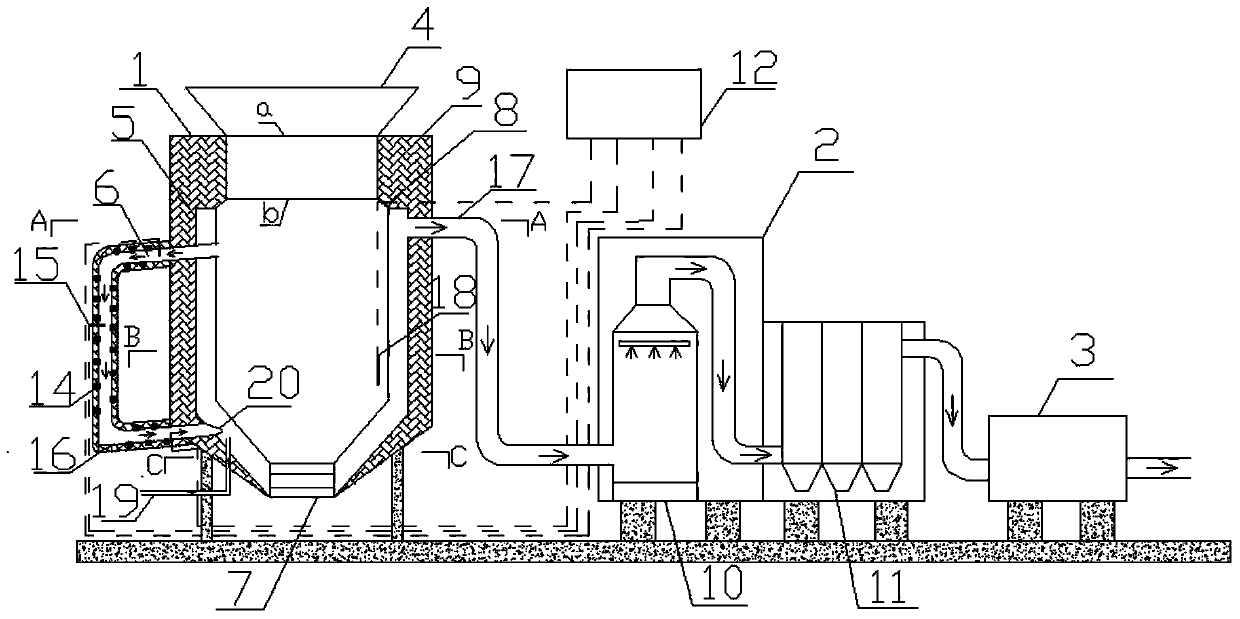

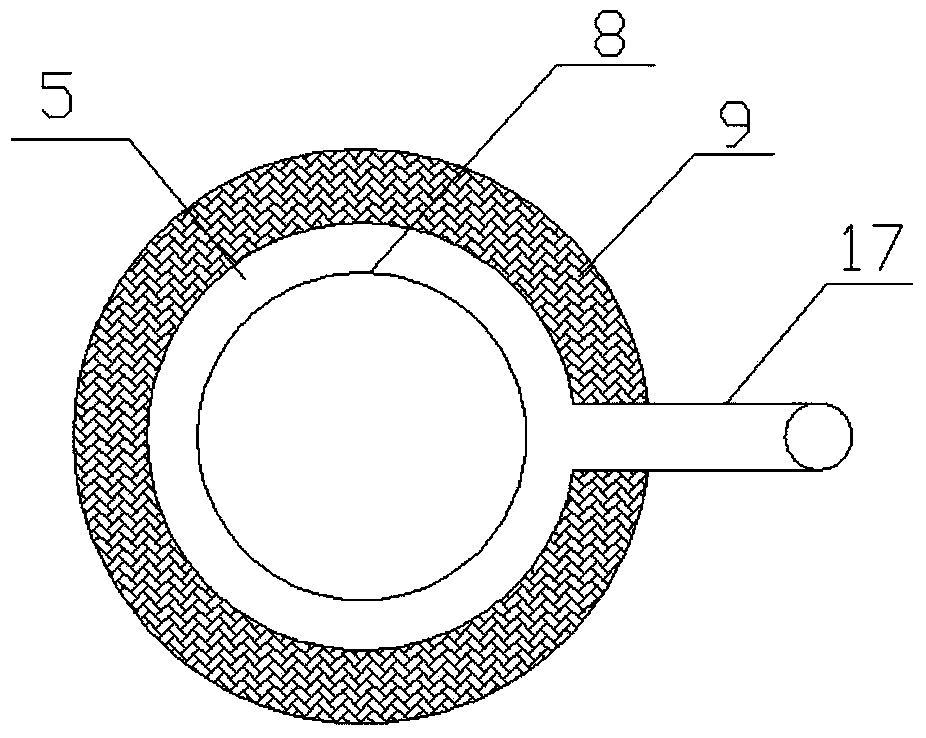

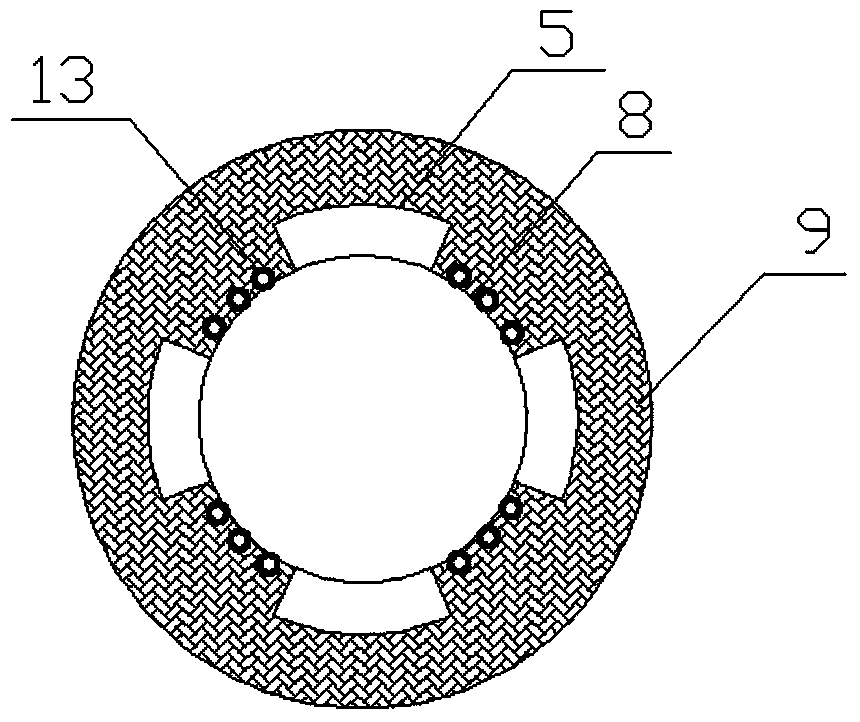

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0025] The medical waste pyrolysis treatment device of the present invention comprises a pyrolysis furnace 1, ancillary equipment 2, and an induced draft fan 3, and the three parts are connected through pipelines. The furnace body is equipped with a feeding device 4 on the top of the furnace body. The feeding device 4 is a double-layer feeding port, which is divided into an upper layer feeding port a and a lower layer feeding port b. A flue gas channel 5 is arranged around the furnace body, and the flue gas The passages 5 communicate with each other at the upper part of the furnace body, and are arranged at intervals in the middle of the furnace body. The first heating wires 13 are arranged between the flues, and the flues 5 at the bottom of the pyrolysis furnace 1 communicate with each other. A pyrolysis gas pipeline 6 is arranged on the side of the furnace body, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com