Catridge shape cover, perforating bullet shell and ultra-deep penetrating perforating bullet

A technology of liner and perforating bullets, which is applied in the fields of mining fluid, wellbore/well components, earthwork drilling and mining, etc. It can solve the problems of failure to meet comprehensive performance requirements, increase the diameter of liner, and increase the risk of blasting guns, etc. problem, to achieve the effect of safety guarantee, lengthening of jet length and improvement of detonation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

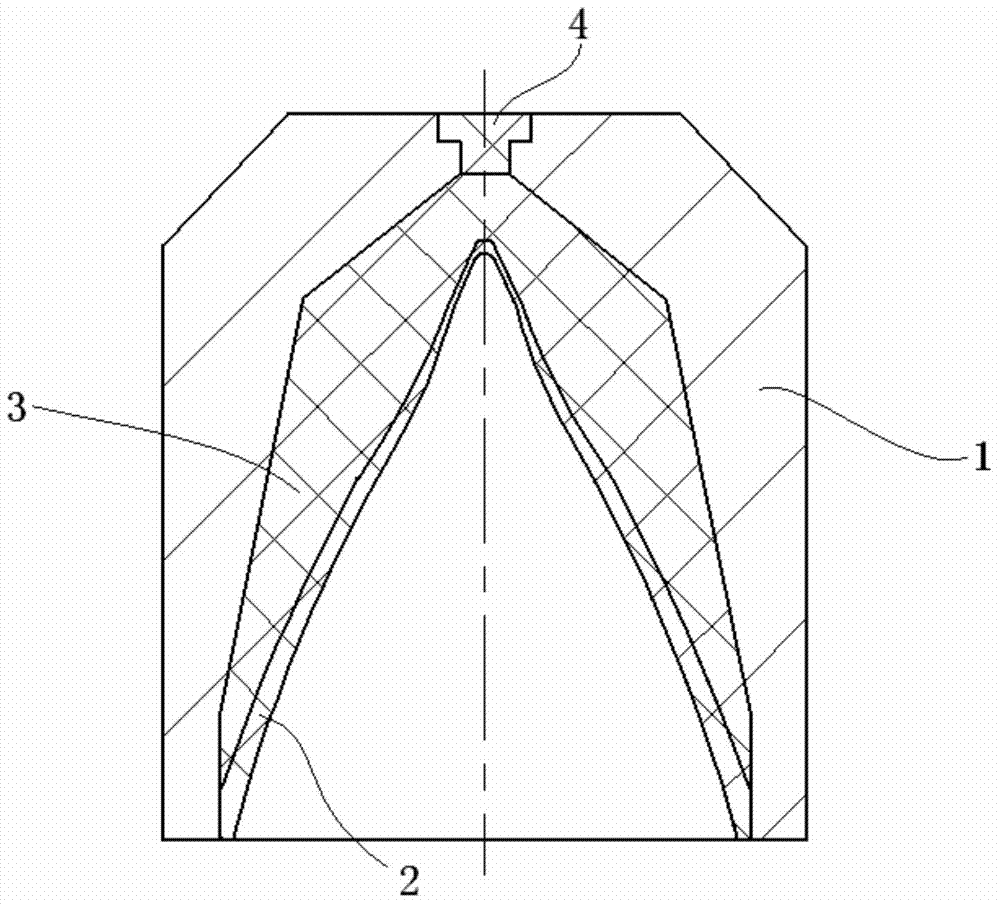

[0041] The size of the perforating charge in this embodiment: outer diameter 52mm, height 64mm.

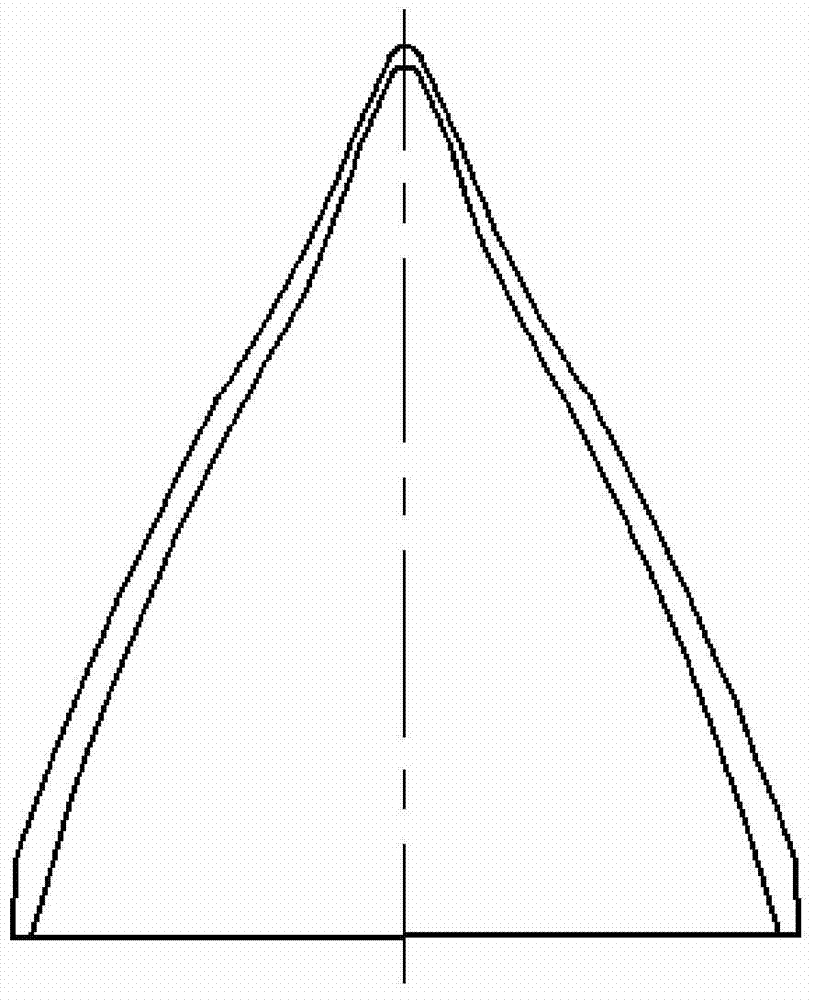

[0042] The structure of the medicine cover is as follows: figure 1 As shown, the relevant dimension is the outer diameter of the cover is 46mm.

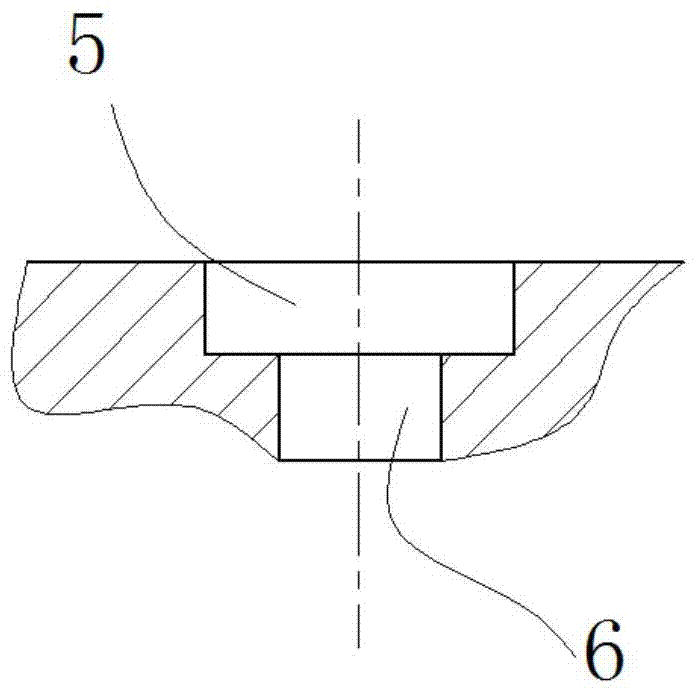

[0043] The structural features of the drug-shaped cover are: the outer busbar of the drug-shaped cover is divided into three sections, the first section from the top of the cover to the bottom of the cover is a straight line (this section is about 0.35 times the height of the cover), and the second section is an arc (or ellipse) ( This section is about 0.2 times the cover height), the third section is a straight line (this section accounts for about 0.45 times the cover height); the busbar in the drug-shaped cover is divided into three sections, the first section is a straight line from top to bottom, and the second section is a circle arc (or ellipse), and the third segment is a circular arc (or parabola); a tangent (or close to tangen...

Embodiment 2

[0050] The size of the perforating charge in this embodiment: outer diameter 52mm, height 64mm.

[0051] The cover outer diameter of this embodiment medicine type cover is 46mm.

[0052] The structural characteristics of the medicine-shaped cover are: Figure 6 As shown, the bus bar outside the drug-type cover is divided into three sections, the first section from top to bottom is a straight line (this section accounts for about 0.35 times the cover height), and the second section is an arc (or ellipse) (this section accounts for about 0.2 times the cover height) Cover height), the third section is a straight line (this section accounts for about 0.45 times the cover height); the busbar in the medicine-shaped cover is divided into 3 sections, the first section is a straight line from top to bottom, and the second section is an arc (or ellipse) , The third segment is arc (or parabola); tangent (or close to tangent) transition is adopted between each segment. Make the drug-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com