Low-yield-point steel buckling-restrained shearing plate damper

A low-yield point steel and anti-buckling technology, which is applied in the direction of earthquake resistance and building components, can solve problems such as excessive out-of-plane buckling and affect the energy dissipation performance of the damper, and achieve small out-of-plane buckling, large plastic deformation capacity, and hysteresis Full back curve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

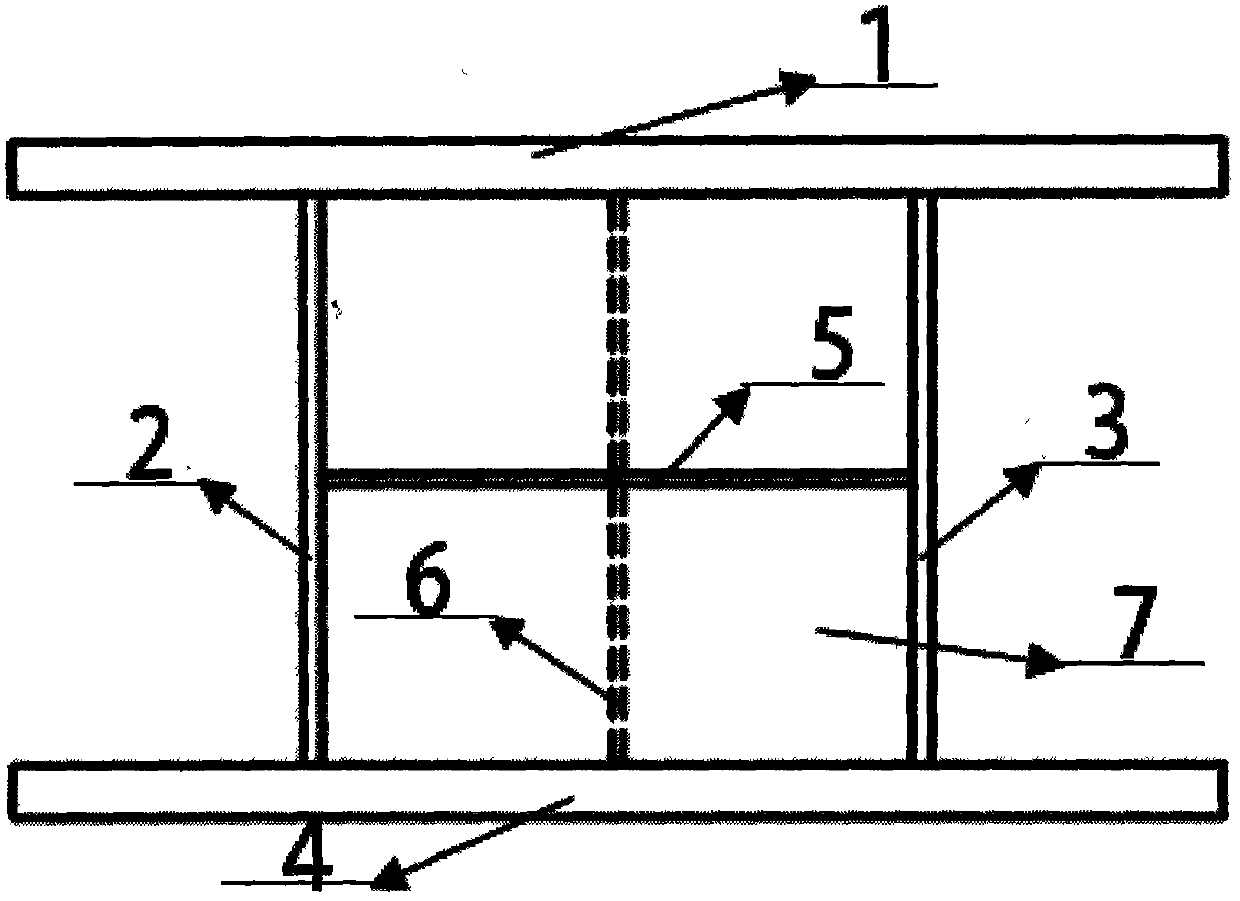

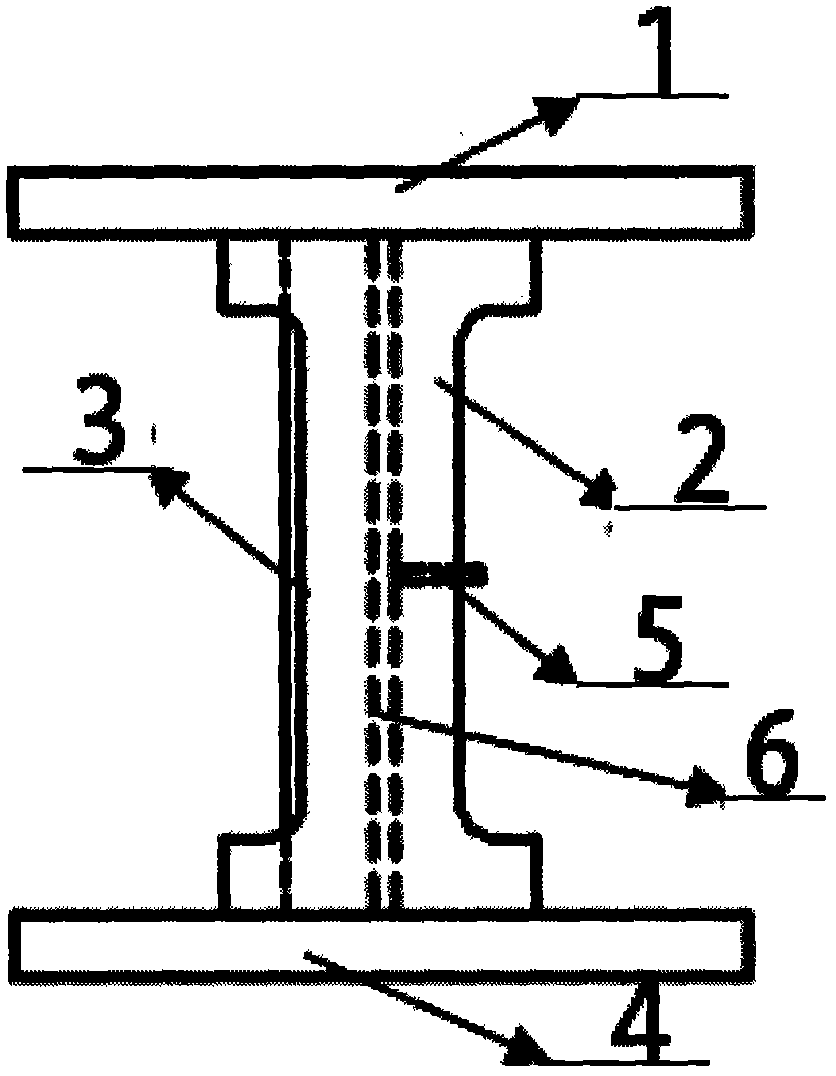

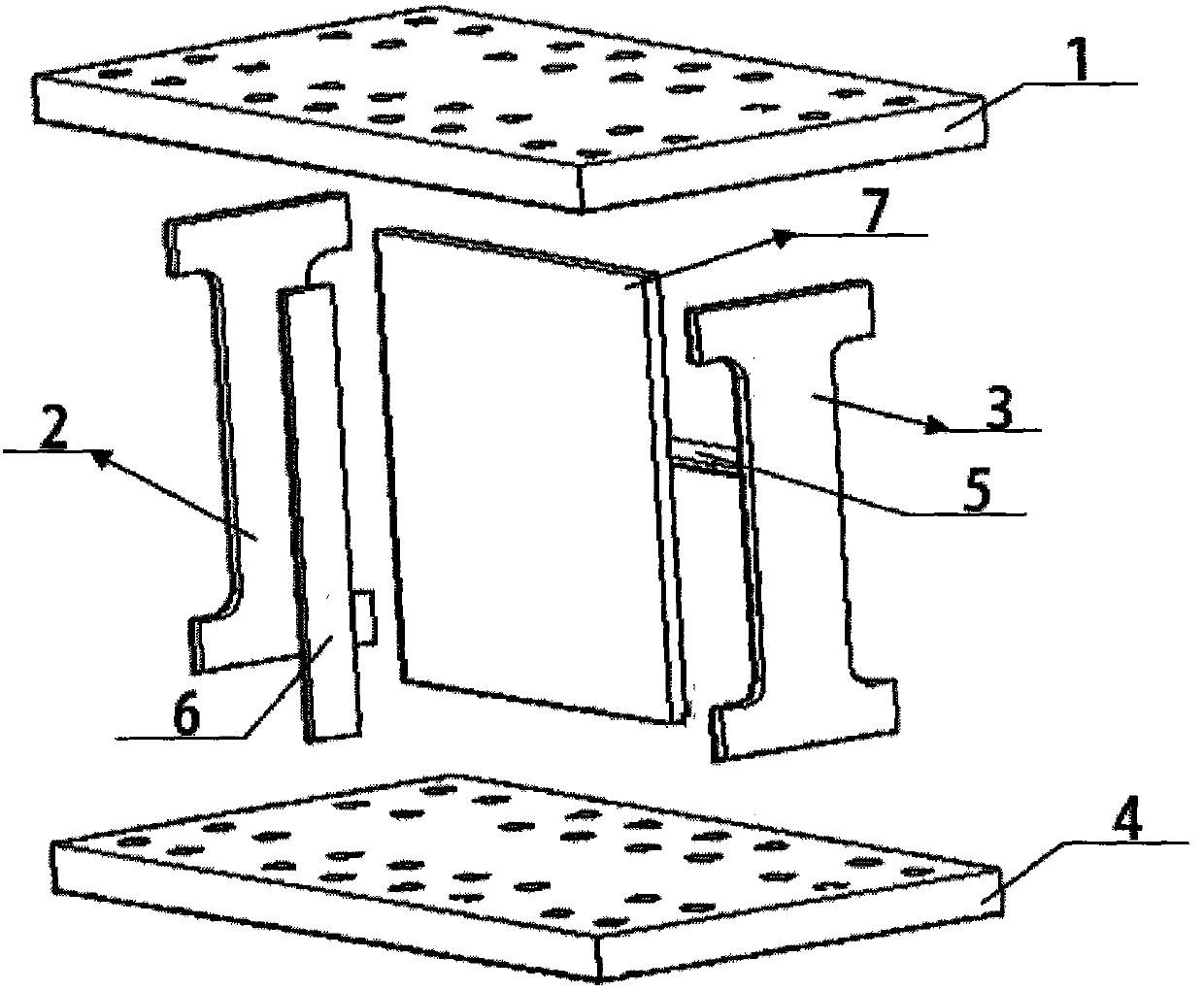

[0019] A steel buckling-resistant shear plate damper with a low yield point, comprising a core steel plate 7, a transverse buckling-resistant stiffener 5, a vertical buckling-resistant stiffener 6, a left flange plate 2, a right flange plate 3, and an upper flange The plate 1 and the lower flange plate 4, the core steel plate 7 are respectively connected with the left and right flange plates 2, 3 and the upper and lower flange plates 1, 4 through penetration welds, and the short side of the transverse buckling stiffener 5 The two ends are respectively welded to the left and right flange plates 2 and 3, the two ends of the short side of the vertical anti-buckling stiffener 6 are respectively welded to the upper and lower flange plates 1 and 4, and the transverse anti-buckling stiffener 5 and the vertical A certain gap is left between the long sides of the anti-buckling stiffener 6 and the core steel plate 7, and the left and right flange plates 2, 3 are connected with the upper ...

Embodiment 2

[0021] In the low yield point steel buckling shear plate damper, continuous welding should be applied between the core steel plate and the left and right flange plates, and the upper and lower flange plates to minimize the influence of welding on the low yield point core steel plate. The rigidity is small, and four supporting columns should be installed between the upper and lower flange plates of the damper to avoid out-of-plane deformation during transportation and installation, and to keep the steel plate stable and safe. The four columns should be removed after installation column.

[0022] Experiments have proved that the low yield point steel shear plate damper with low yield point proposed by the present invention is an appropriate improvement to the traditional low yield point steel shear plate damper, by setting transverse and vertical anti-buckling stiffeners on both sides of the core plate , the out-of-plane deformation of the damper is well restrained, and a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com