Antibiotic polypropylene resin composition and preparation method thereof

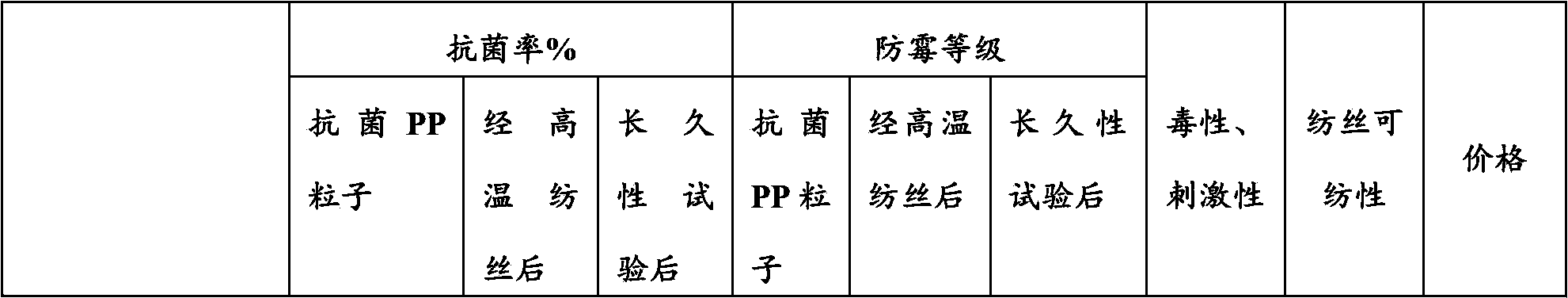

A resin composition, antibacterial polypropylene technology, applied in the direction of single-component polyolefin artificial filament, etc., can solve the problems of expensive antibacterial masterbatch, antibacterial agent antibacterial efficiency, speed, broad spectrum, durable heat resistance, compatibility Toxicity, processing performance, toxicity, lack of irritation, loss, etc., to achieve high-efficiency antibacterial and anti-mildew functions and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

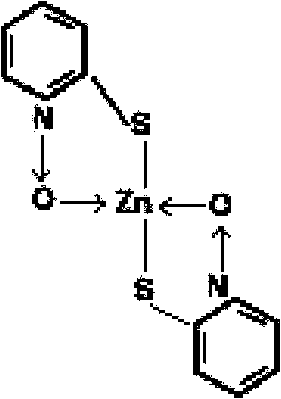

[0023] Get 1 kg of base material polypropylene resin, measure and mix the above-mentioned antibacterial agent, lubricant, antioxidant and polypropylene resin base material respectively, wherein the weight ratio of antibacterial agent, lubricant, antioxidant and polypropylene resin is 1 : 1.5: 1.5: 1000, the weight ratio of zinc pyrithione and 2,4,4'-trichloro-2'-hydroxydiphenyl ether in the compound antibacterial agent is 0.85:0.15, glyceryl stearate in the lubricant 1. The weight ratio of calcium stearate and erucamide is 0.5:0.5:0.5, and the weight ratio of antioxidant 1010 and antioxidant 168 in the antioxidant is 0.5:1;

[0024] Put into a twin-screw extruder for melt mixing and granulation, wherein the residence time of the material in the screw is 1 minute, the temperature of the screw is controlled at 210°C, and the speed of the screw is controlled at 300 rpm;

[0025] The obtained antibacterial polypropylene resin composition particles are finished products after being...

Embodiment 2

[0027] Get 1kg of base material polypropylene resin, measure and mix the above-mentioned antibacterial agent, lubricant, antioxidant and polypropylene resin base material respectively, wherein the weight ratio of antibacterial agent, lubricant, antioxidant and polypropylene resin is 1.2 : 1.8: 1.5: 1000, the weight ratio of zinc pyrithione and 2,4,4'-trichloro-2'-hydroxydiphenyl ether in the compound antibacterial agent is 1.0:0.20, glyceryl stearate in the lubricant 1. The weight ratio of calcium stearate and erucamide is 0.6:0.7:0.5, and the weight ratio of antioxidant 1010 and antioxidant 168 in the antioxidant is 0.5:1;

[0028] Put into a twin-screw extruder for melt mixing and granulation, wherein the residence time of the material in the screw is 4 minutes, the temperature of the screw is controlled at 145°C, and the speed of the screw is controlled at 100 rpm;

[0029] The obtained antibacterial polypropylene resin composition particles are finished products after bein...

Embodiment 3

[0031] Get 1 kg of base material polypropylene resin, measure and mix the above-mentioned antibacterial agent, lubricant, antioxidant and polypropylene resin base material respectively, wherein the weight ratio of antibacterial agent, lubricant, antioxidant and polypropylene resin is 0.9 : 1.4: 1.5: 1000, the weight ratio of zinc pyrithione and 2,4,4'-trichloro-2'-hydroxydiphenyl ether in the compound antibacterial agent is 0.80:0.10, glyceryl stearate in the lubricant 1. The weight ratio of calcium stearate and erucamide is 0.5:0.6:0.3, and the weight ratio of antioxidant 1010 and antioxidant 168 in the antioxidant is 0.5:1;

[0032] Put into a twin-screw extruder for melt mixing and granulation, wherein the residence time of the material in the screw is 3 minutes, the temperature of the screw is controlled at 180°C, and the speed of the screw is controlled at 150 rpm;

[0033] The obtained antibacterial polypropylene resin composition particles are finished products after be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com