Segmented steel belt and segmented steel belt system using same

A technology for steel strips and annular steel strips, applied in the field of segmented steel strip systems, can solve the problems of easy cracking of edges, complicated maintenance and adjustment, uneven surface of steel strips, etc., and achieve uniform force, cost reduction, and synchronization of cooling and crystallization time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

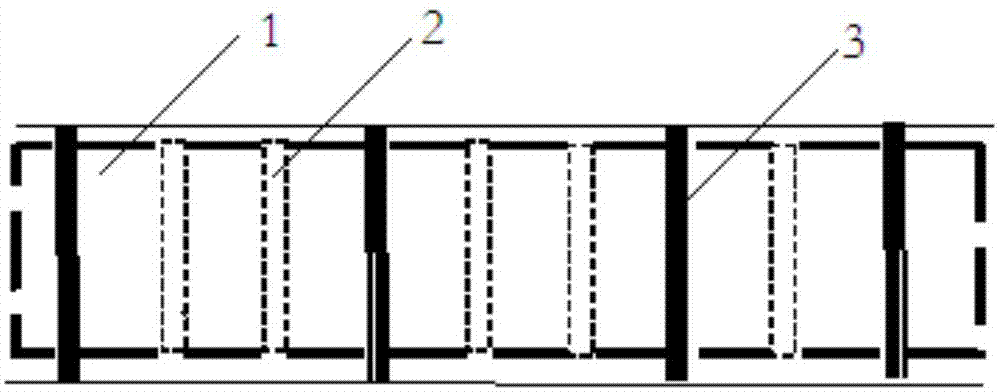

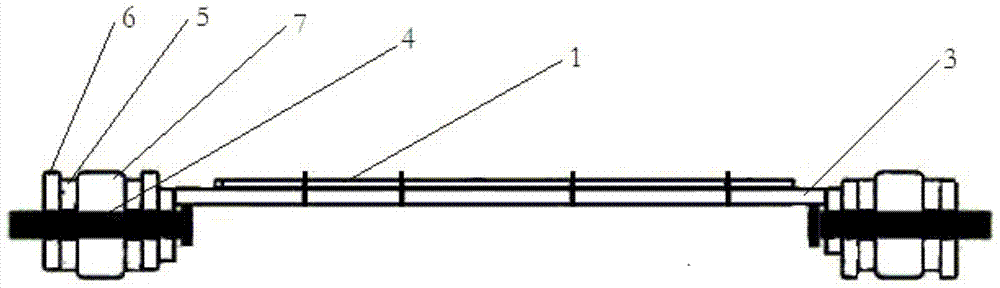

[0016] see figure 1 , a segmented steel strip provided by the embodiment of the present invention, including a steel strip block 1, a steel strip block connecting shaft 2, and a connecting force bearing shaft 3, there are multiple steel strip blocks 1, and each steel strip block connecting shaft 2 passes through Two adjacent steel belt blocks 1 are fixedly connected by bolts to form a complete ring-shaped steel belt; the connecting force shaft 3 is fixed on the steel belt block 1 at a fixed distance, and the length of the connecting force shaft 3 is longer than the steel belt Block 1 width; Connect the stressed shaft 3 thick 2mm, wide 30mm; Connect the two ends of the stressed shaft 3 to the opposite side of the fixed steel belt block 1, and the edge is perpendicular to the steel belt block 1, and the edge is provided with a fixed holes. The steel belt block 1 is connected with the connecting force bearing shaft 3 by means of bolts. The thickness of the steel strip block 1 i...

Embodiment 2

[0019] see figure 1 , a segmented steel strip provided by the embodiment of the present invention, including a steel strip block 1, a steel strip block connecting shaft 2, and a connecting force bearing shaft 3, there are multiple steel strip blocks 1, and each steel strip block connecting shaft 2 passes through Two adjacent steel belt blocks 1 are fixedly connected by bolts to form a complete ring-shaped steel belt; the connecting force shaft 3 is fixed on the steel belt block 1 at a fixed distance, and the length of the connecting force shaft 3 is longer than the steel belt block 1 Width; the connecting force shaft 3 is 2 mm thick and 30 mm wide; the two ends of the connecting force shaft 3 are folded to the opposite side of the fixed steel belt block 1, and the edge is perpendicular to the steel belt block 1, and the edge is provided with a fixed hole. The steel belt block 1 is connected with the connecting force bearing shaft 3 by means of bolts. The thickness of the str...

Embodiment 3

[0022] see figure 1 , a segmented steel strip provided by the embodiment of the present invention, including a steel strip block 1, a steel strip block connecting shaft 2, and a connecting force bearing shaft 3, there are multiple steel strip blocks 1, and each steel strip block connecting shaft 2 passes through Two adjacent steel belt blocks 1 are fixedly connected by bolts to form a complete ring-shaped steel belt; the connecting force shaft 3 is fixed on the steel belt block 1 at a fixed distance, and the length of the connecting force shaft 3 is longer than the steel belt Block 1 width; Connect the stressed shaft 3 thick 2mm, wide 30mm; Connect the two ends of the stressed shaft 3 to the opposite side of the fixed steel belt block 1, and the edge is perpendicular to the steel belt block 1, and the edge is provided with a fixed holes. The steel belt block 1 is connected with the connecting force bearing shaft 3 by means of bolts. The thickness of the steel strip block 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com