New integrated station for waste collection, compression and loading

A new type of garbage collection technology, applied in the field of garbage collection stations, can solve the problems of increased labor intensity of workers, easy scattering of garbage, and inconvenient loading of vehicles, and achieve the goal of convenient and fast loading process, convenient and fast loading, and reduced transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

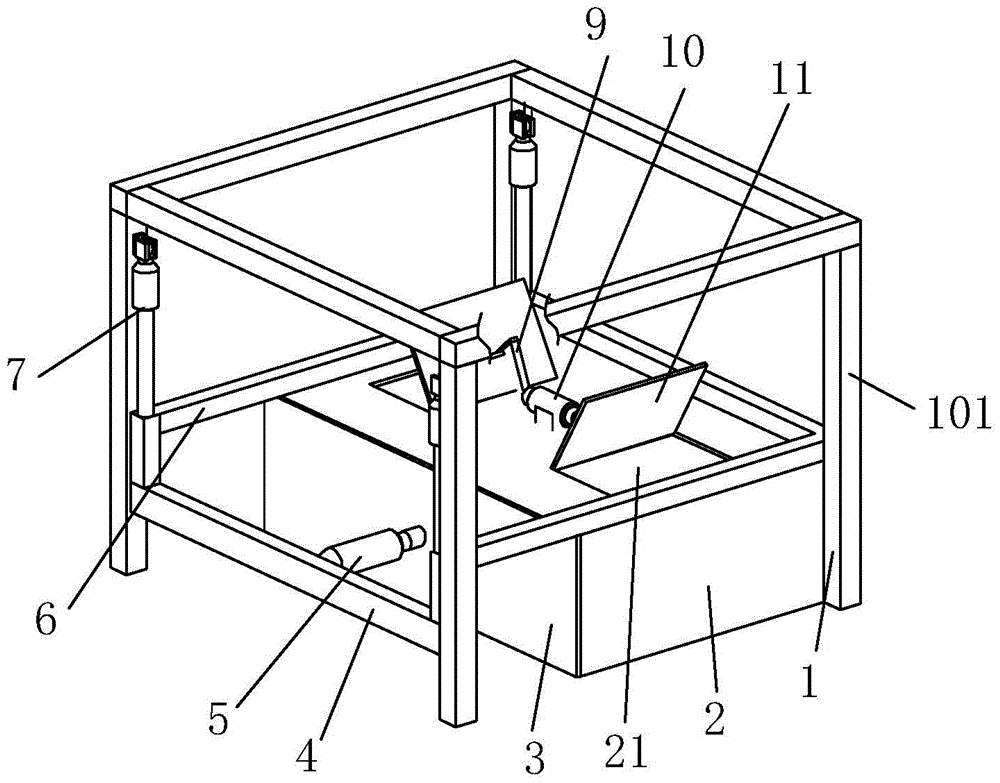

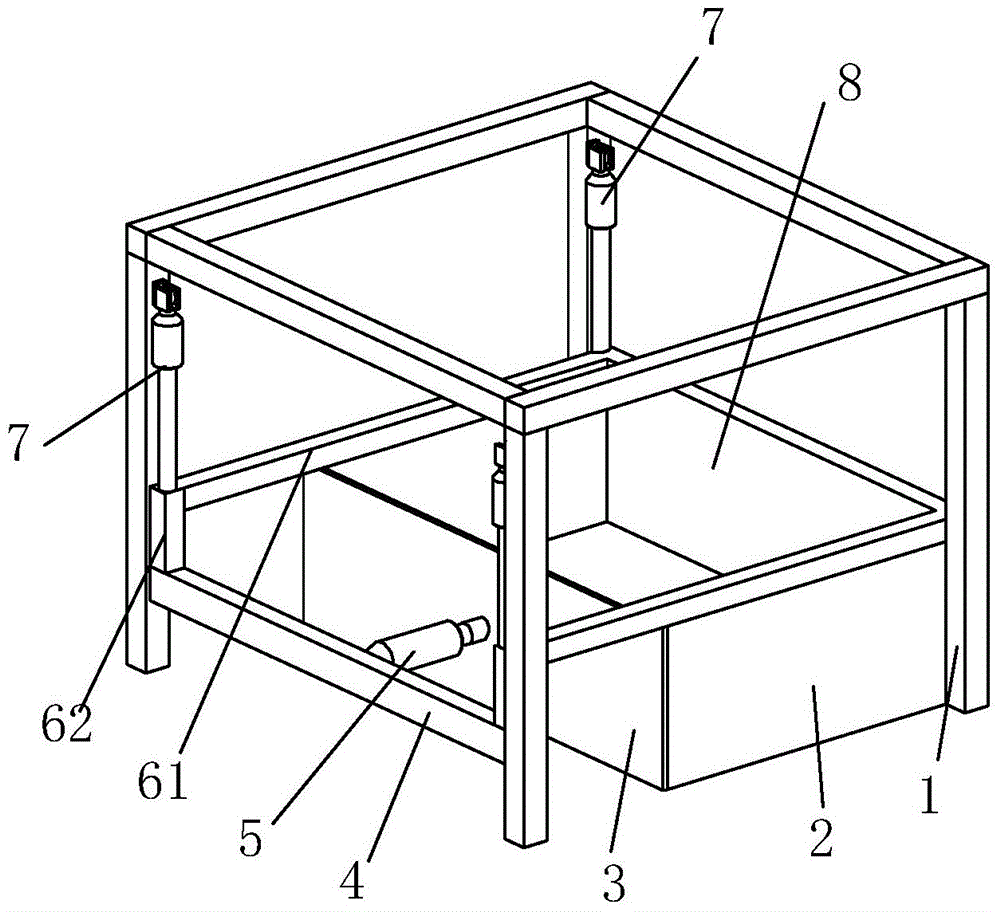

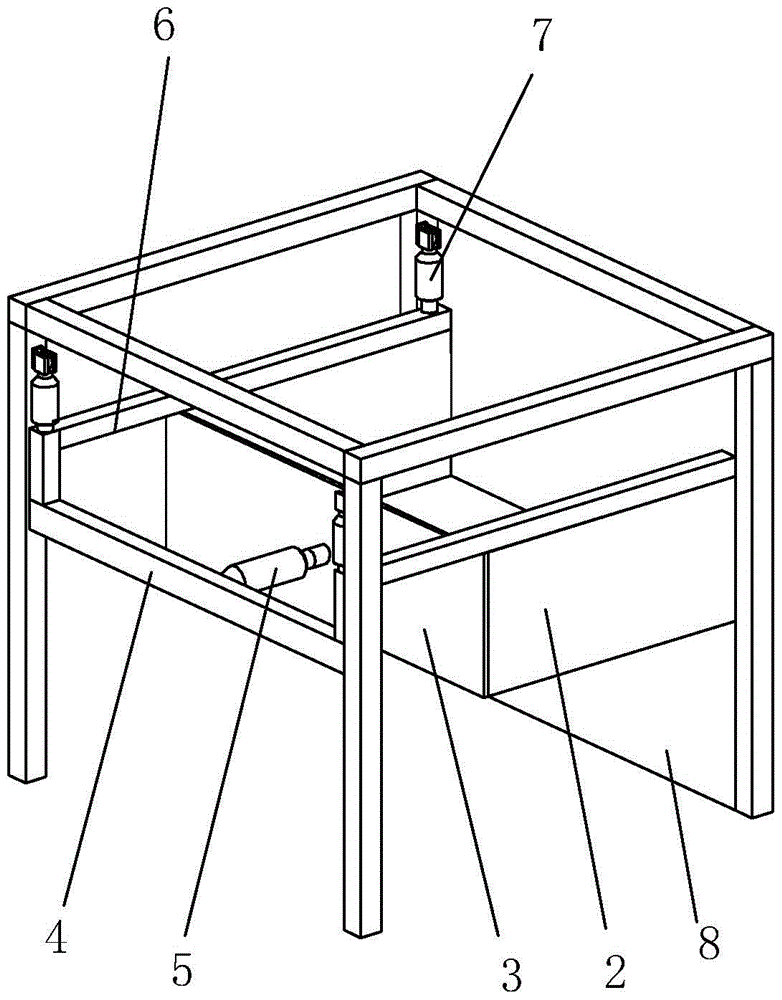

[0017] Embodiment 1: A new type of waste collection, compression and loading integrated station, including a frame 1 composed of 4 longitudinal beams 101 and 4 cross beams, a compression plate 3, a main box body 2, a fixed plate 8, a compression cylinder 5, a lifting Oil cylinder 7, collection oil cylinder 10 and compression oil cylinder fixed beam 4, described main box body comprises bottom plate, top plate and 2 side plates, the height of described frame 1 is higher than main box body 2, the described fixed plate 8 The height is lower than the height of the frame, the fixed plate is installed between the two longitudinal beams of the frame, the compression plate is located in the main box, when the main box is not lifted for compression operation, the compression plate, the main box and the The fixed plate forms an airtight structure, the two ends of the compression cylinder 5 are respectively connected with the compression cylinder fixed beam 4 and the compression plate 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com