Fixed auxiliary member for drilling inner hole in wooden product

A technology for auxiliary components and wood products, which is used in drilling machines, woodworking lathes, manufacturing tools, etc., and can solve the problems of difficult clamping of chucks, hazards, and easy to throw out of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

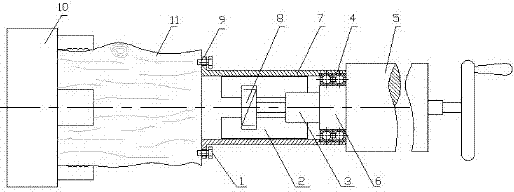

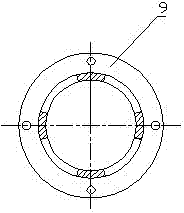

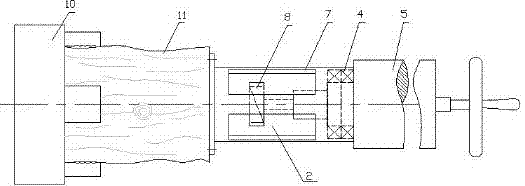

[0011] Implementation case: A fixed auxiliary component for drilling inner holes in wood products, including a chuck 10, a tailstock 5, a tailstock shaft 6, a drill sleeve 3 and a drill bit 8, and a fixed auxiliary component is installed on the tailstock shaft 6, and the fixed auxiliary component It includes: a jacket 7, one end of which is provided with a flange 9, and the other end is provided with a bearing 4; the jacket 7 is provided with a debris outlet 2; the flange 9 is provided with screws 1, at least two of which are provided; the bearing 4 Sleeved on the tailstock shaft 6; there are at least two bearings 4.

[0012] On the chuck 10, the workpiece 11 is clamped, and the other end of the workpiece 11 is fixed with the screw 1 on the flange 9. When the machine tool is opened, the drill bit 8 can punch holes on the workpiece 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com