Special machine tool for multi-surface mill

A special machine tool and face milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of difficulty in meeting the requirements of verticality tolerance, time-consuming and labor-intensive processing, and positioning errors, etc., to achieve compact structure and improve processing efficiency , The effect of high milling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

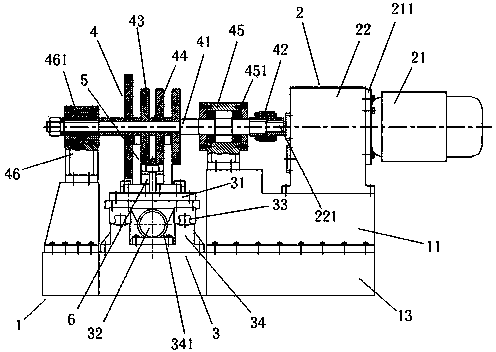

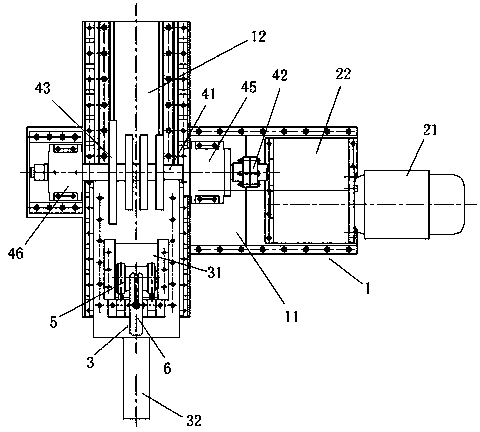

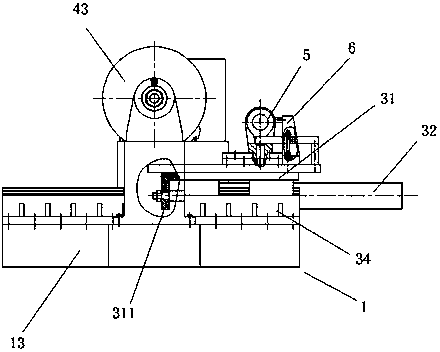

[0015] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a fuselage 1, a power unit 2, a feeding device 3 and a milling cutter device 4. The fuselage 1 is in the shape of a cross and includes a longitudinal base 11 and a transverse base 12 connected as a whole. The longitudinal base 11, the transverse base 12 and the common base 13 on the lower side are fixedly connected as a whole by a plurality of fasteners. The longitudinal base 11, the transverse base 12 and the common base 13 can be welded steel structures, and can also be cast iron or cast steel structures. The present invention is a welded steel structure, which is convenient for a small amount of manufacturing and reduces the manufacturing cycle and cost of wooden molds.

[0016] The power unit 2 is arranged on the right end of the longitudinal base 11, and includes a drive motor 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com