Method and device for manufacturing semi-solid metal by using serpentine vibration channel

A semi-solid metal and serpentine channel technology, which is applied in the field of semi-solid metal forming, can solve the problems of increasing the number of metal remelting and melting energy consumption, reducing the capacity of semi-solid metal, and increasing the difficulty of cleaning and hanging materials, so as to reduce the quantity and melt The effect of energy consumption, quantity increase, and material hanging speed decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

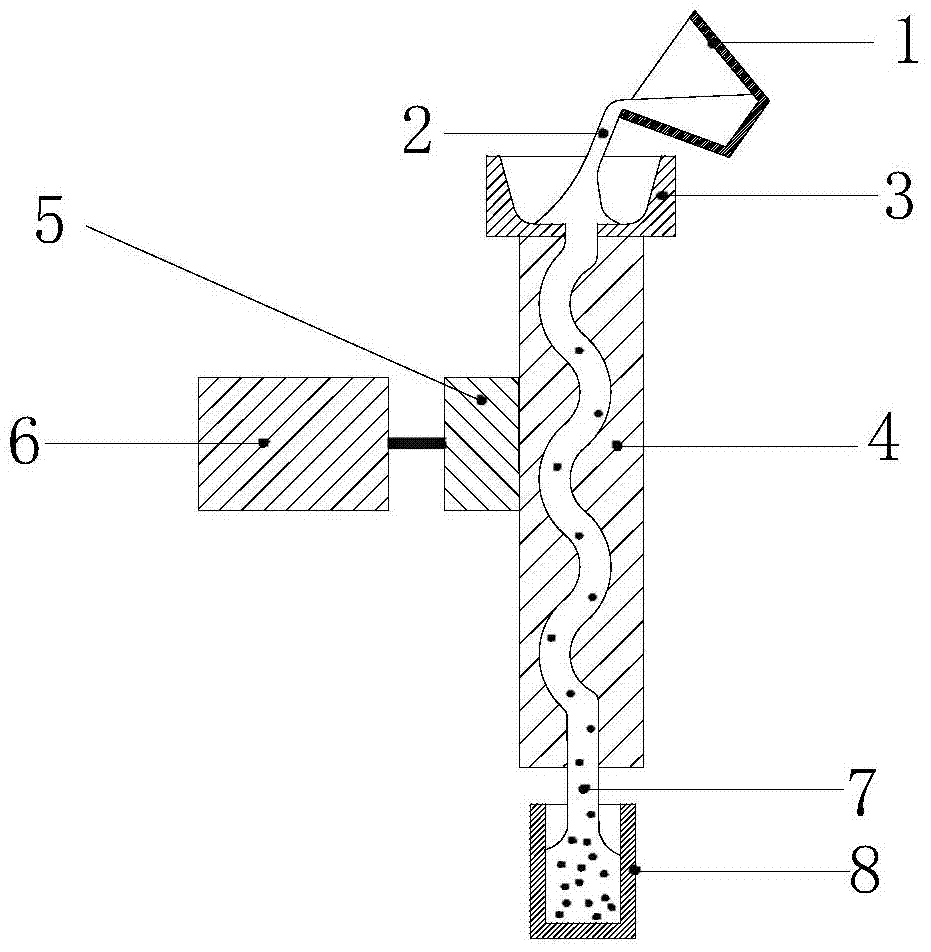

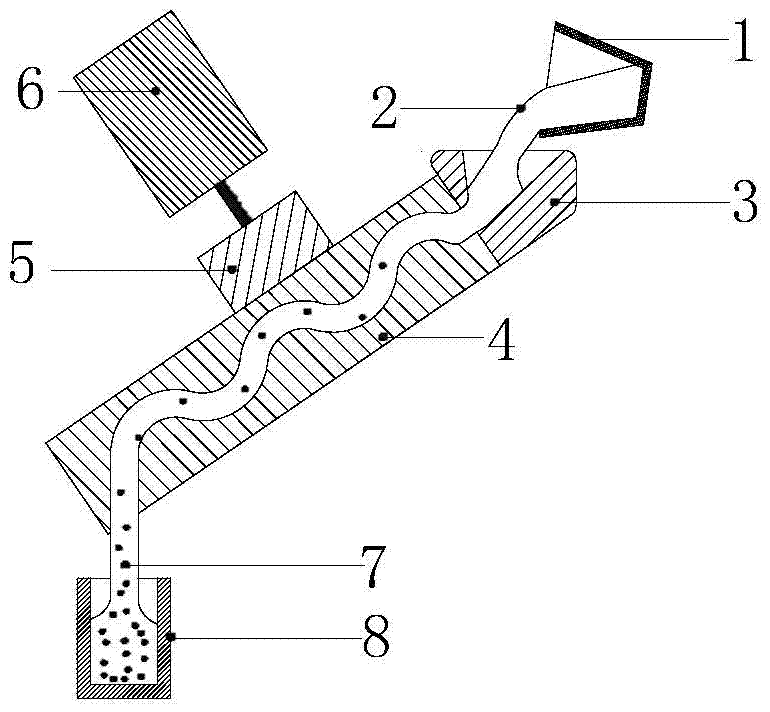

[0026] refer to figure 1 , which is the first form of vibrating vertical serpentine passage process and device for preparing semi-solid metal provided according to the above-mentioned technical characteristics. The vibrating vertical serpentine channel device is provided with a ladle 1, and the ladle 1 is mixed with the overheated ZL101A aluminum alloy liquid 2 (i.e. hypoeutectic Al-7 wt %Si-0.45 wt %Mg aluminum alloy, which is equivalent to the American brand A356 aluminum alloy); the overheated ZL101A aluminum alloy liquid 2 is connected to the sprue cup 3; the sprue cup 3 is connected to the serpentine channel 4, and the height of the serpentine channel 4 is 1000mm, inner diameter is 100mm, there are 6 internal curved bends in the serpentine channel 4, and the serpentine channel 4 is made of graphite; the serpentine channel 4 is connected with the electromechanical vibrator 5, and the amplitude of the electromechanical vibrator 5 is 4mm, the vibration frequency is 10Hz;...

Embodiment 2

[0028] refer to figure 1 , which is the first form of vibrating vertical serpentine passage process and device for preparing semi-solid metal provided according to the above-mentioned technical characteristics. The vibrating vertical serpentine channel device is provided with a ladle 1, and the ladle 1 is mixed with the overheated ZL117 aluminum alloy liquid 2 (i.e. hypereutectic Al-20 wt %Si-1.8 wt %Cu-1.0 wt %RE aluminum alloy); the superheated ZL117 aluminum alloy liquid 2 is connected with the sprue cup 3; the sprue cup 3 is connected with the serpentine channel 4, the height of the serpentine channel is 400mm, and the inner diameter is 25mm. There are 3 internal curved bends, and the material of the serpentine channel is graphite; the serpentine channel 4 is connected with the electro-excited mechanical vibrator 5, the amplitude of the electro-excited mechanical vibrator 5 is 4 mm, and the vibration frequency is 5 Hz; The mechanical vibrator 5 is connected with the ...

Embodiment 3

[0030] refer to figure 1 , which is the first form of vibrating vertical serpentine passage process and device for preparing semi-solid metal provided according to the above-mentioned technical characteristics. The vibrating vertical serpentine channel device is provided with a ladle 1, which is mixed with superheated 2024 aluminum alloy liquid 2 (that is, Al-4 wt %Cu-1.5 wt %Mg-0.6 wt %Mn aluminum alloy); the superheated 2024 aluminum alloy liquid 2 is connected with the sprue cup 3; the sprue cup 3 is connected with the serpentine channel 4, the height of the serpentine channel is 800mm, and the inner diameter is 25mm, the serpentine channel There are 10 internal arc bends, and the material of the serpentine channel is graphite; the serpentine channel 4 is connected with the electromechanical vibrator 5, the amplitude of the electromechanical vibrator 5 is 0.2mm, and the vibration frequency is 100Hz; The excited mechanical vibrator 5 is connected with the electric vibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com