Variable Angle Robot Hemming Tool

A robot and angle technology, which is applied in the field of robot hemming tools, can solve the problems of inability to realize and reduce the movement speed of the robot, and achieve the effect of being beneficial to control, improving movement efficiency and reducing posture changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

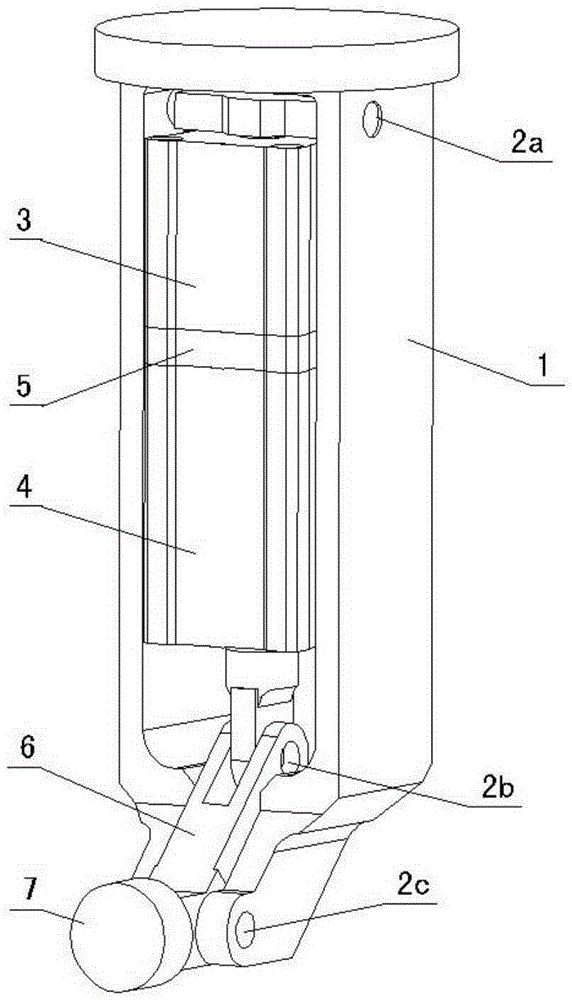

[0021] See figure 1 The structure of the variable-angle robot hemming tool in this embodiment is:

[0022] The robot connection frame 1 is set. The upper part of the robot connection frame 1 is provided with a first hinge 2a, and an upper cylinder 3 is installed on the first hinge 2a with the rod end of its piston rod, so that the upper cylinder 3 can be mounted on the first hinge 2a swings with the hinge axis as the center; and the upper cylinder 3 is back-to-back mounted with the lower cylinder 4 through the connecting plate 5. The lower cylinder 4 is connected with the tail of the connecting rod 6 through the second hinge 2b through the rod end of the piston rod. The front end of the rod 6 is connected to the robot connection frame 1 through a third hinge 2c, and the roller 7 is fixedly arranged on the front end surface of the connecting rod 6.

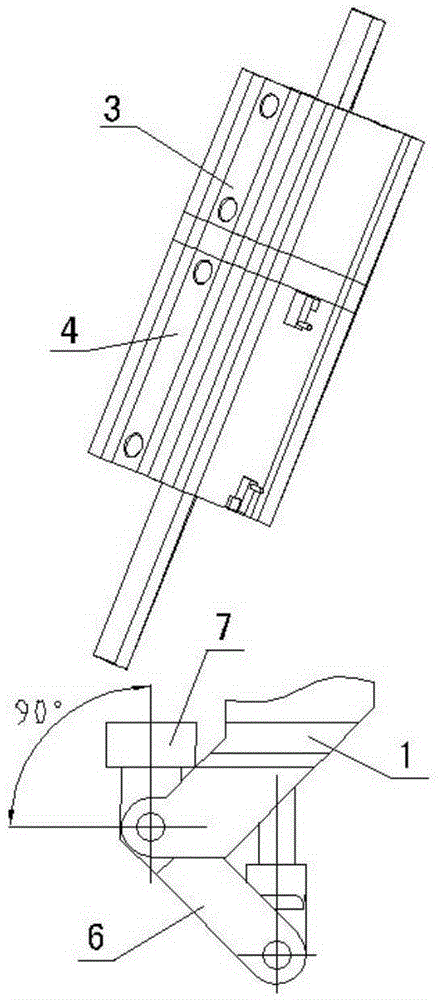

[0023] To avoid interference, such as figure 1 As shown, in this embodiment, the axis of the roller 7 and the connecting rod 6 form an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com