Multi-freedom-degree mechanical arm used for engineering vehicle and engineering vehicle

A technology of engineering vehicles and mechanical arms, which is applied to vehicle components, lifting devices, transportation and packaging, etc., can solve problems such as difficult to guarantee stability, slow replacement speed, and limited function integration, and achieve the reduction of urban management costs and the range of changes The effect of large and extended functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

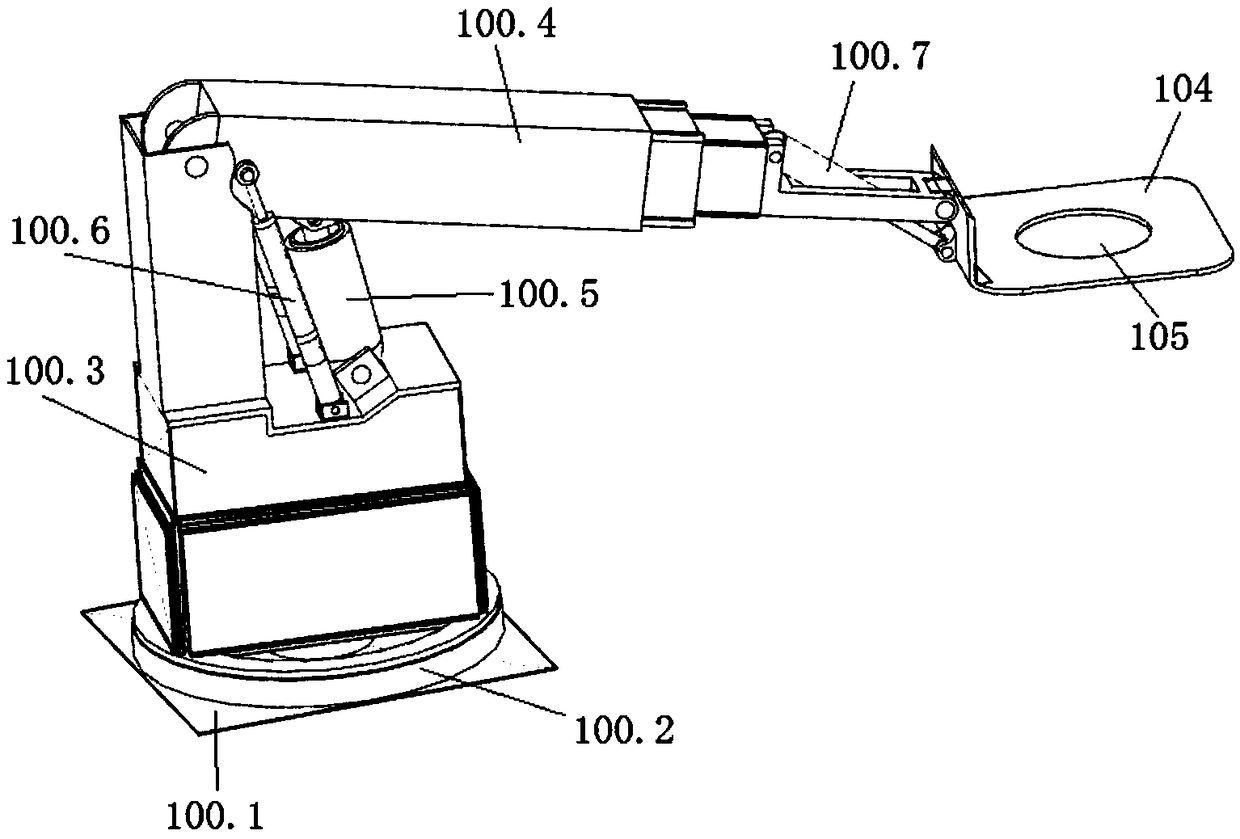

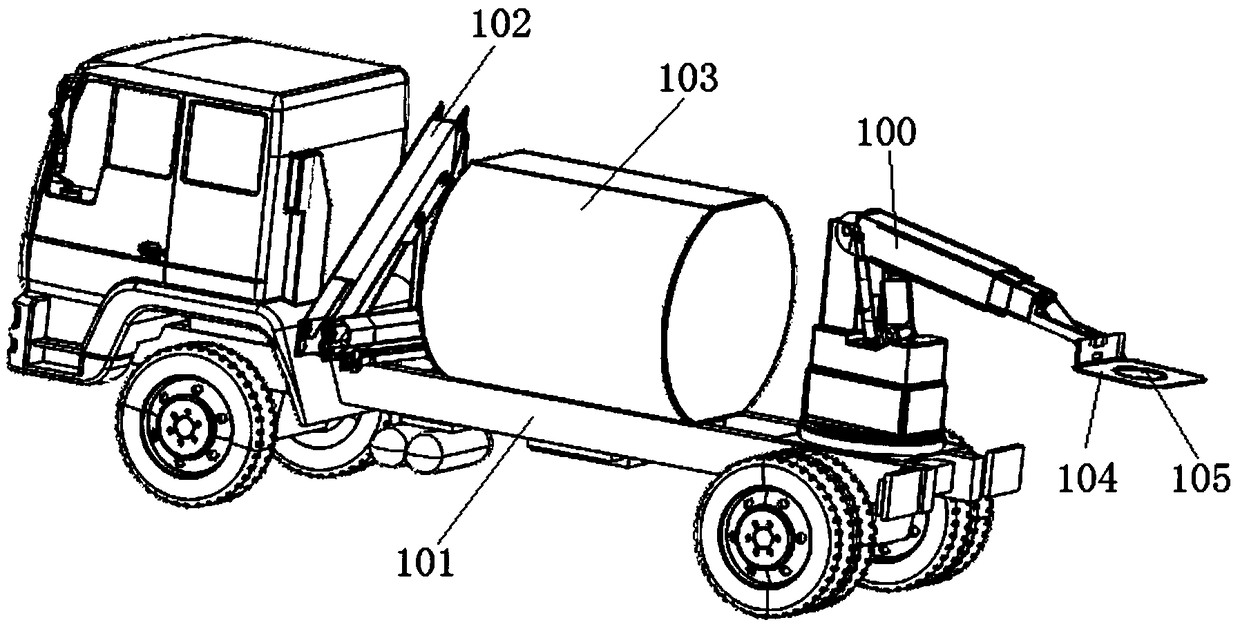

[0038] see figure 1 , a multi-degree-of-freedom mechanical arm for engineering vehicles, including a base 100.1, a turntable 100.2, a column 100.3, a beam 100.4, a pitch drive cylinder 100.5, a horizontal adjustment cylinder A100.6, and a horizontal adjustment cylinder B100.7. The base 100.1 is used for It is fixedly connected with the body chassis 101, the turntable 100.2 is fixed on the base 100.1, the bottom of the column 100.3 is fixed on the turntable 100.2, the column can rotate with the turntable, one end of the beam 100.4 is hinged to the top of the column 100.3, and the other end is connected to the mounting platform 104 of the engineering vehicle. The outer side wall is hinged, and the mounting platform 104 table top is horizontally arranged and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com