Vibration pump type wind power impurity removing mechanism for peanut separator

A peanut cleaning machine technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as low work efficiency, high labor intensity, and difficult manual cleaning. To achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

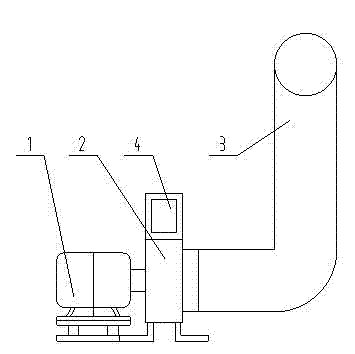

[0013] As shown in the figure, the wind force impurity removal mechanism of the vibrating pump type peanut cleaning machine includes a motor 1, a centrifugal suction fan 2, a suction duct 3 and an air outlet 4; wherein one end of the centrifugal suction fan 2 is connected to one end of the suction duct 3 Connect, the other end of the centrifugal suction fan 2 is connected with the air outlet 4, and the centrifugal suction fan 2 is connected with the motor 1.

[0014] The wind force impurity removal mechanism of the vibrating pump type peanut cleaning machine of the present invention, the motor 1 drives the centrifugal suction fan 2 to rotate, the centrifugal fan 2 and the suction pipe 3 form a negative pressure, and the peanuts are lifted by the fully enclosed belt scoop conveying mechanism During the process of pouring to the top and falling into the vibrating screen, impurities and peanuts are dynamically separated. At this time, the light impurities are sucked out from the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com