Windmill rotary vane turning device and wind-powered electricity generation device equipped with same

A windmill rotation and steering device technology, which is applied to wind engines, wind generator components, and wind power generation in the same direction as the wind, can solve problems such as low frequency of use, increased manufacturing costs of wind power generation devices, and increased manufacturing costs. Achieve the effect of cheap structure and retain complete security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, refer to Figure 1 to Figure 8 Embodiments of the present invention will be described.

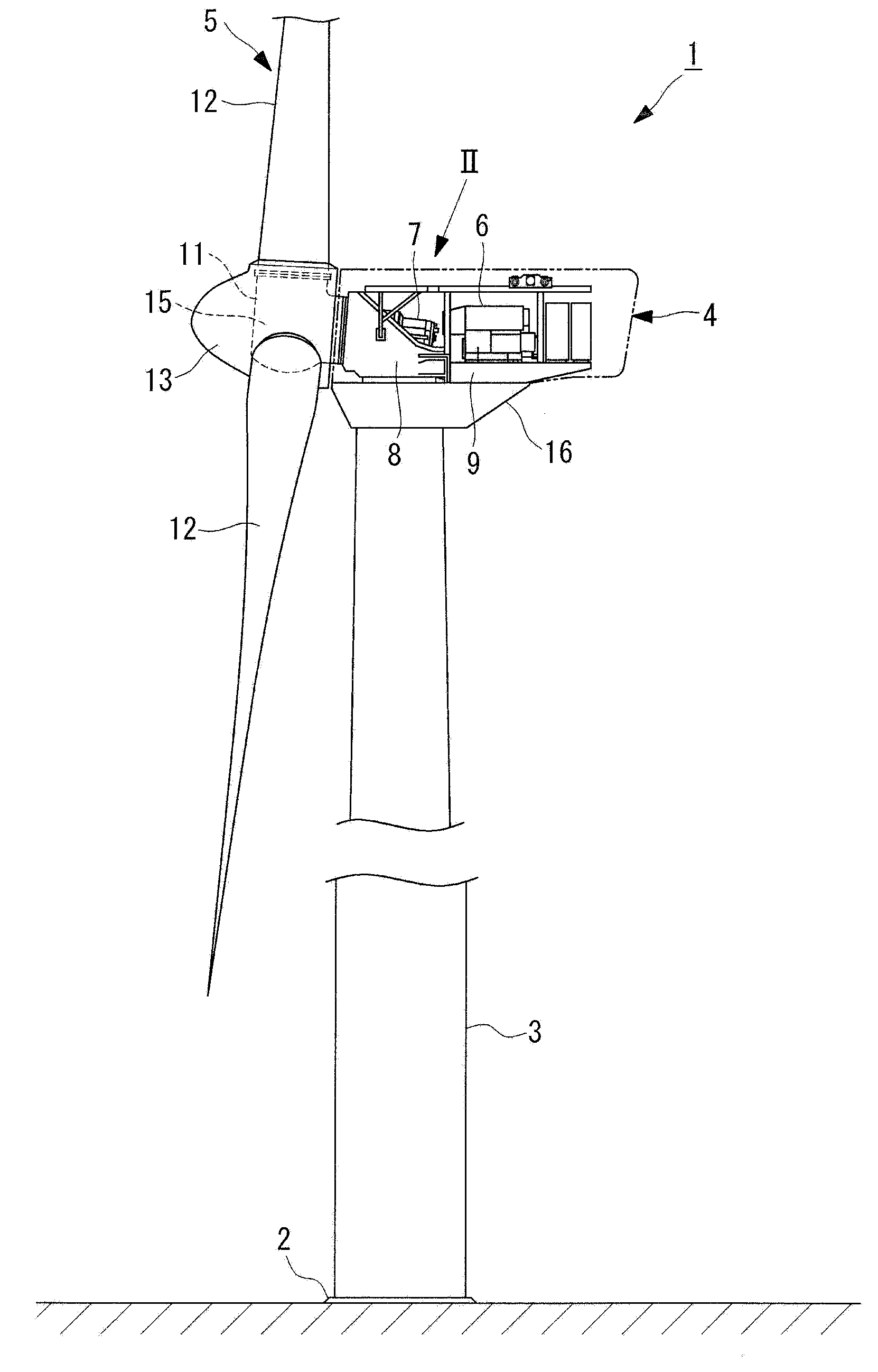

[0045] figure 1 It is a side view showing an example of a wind power generator to which the steering device according to the embodiment of the present invention can be applied. The wind power generation device 1 includes: a tower 3 erected on the upper surface of a reinforced concrete foundation 2 buried in the ground; a pod 4 installed on the upper end of the tower 3; a windmill rotor 5, It is installed in the pod 4 ; the generator 6 and the speed increaser 7 are accommodated inside the pod 4 and generate electricity by the rotation of the windmill rotor blade 5 .

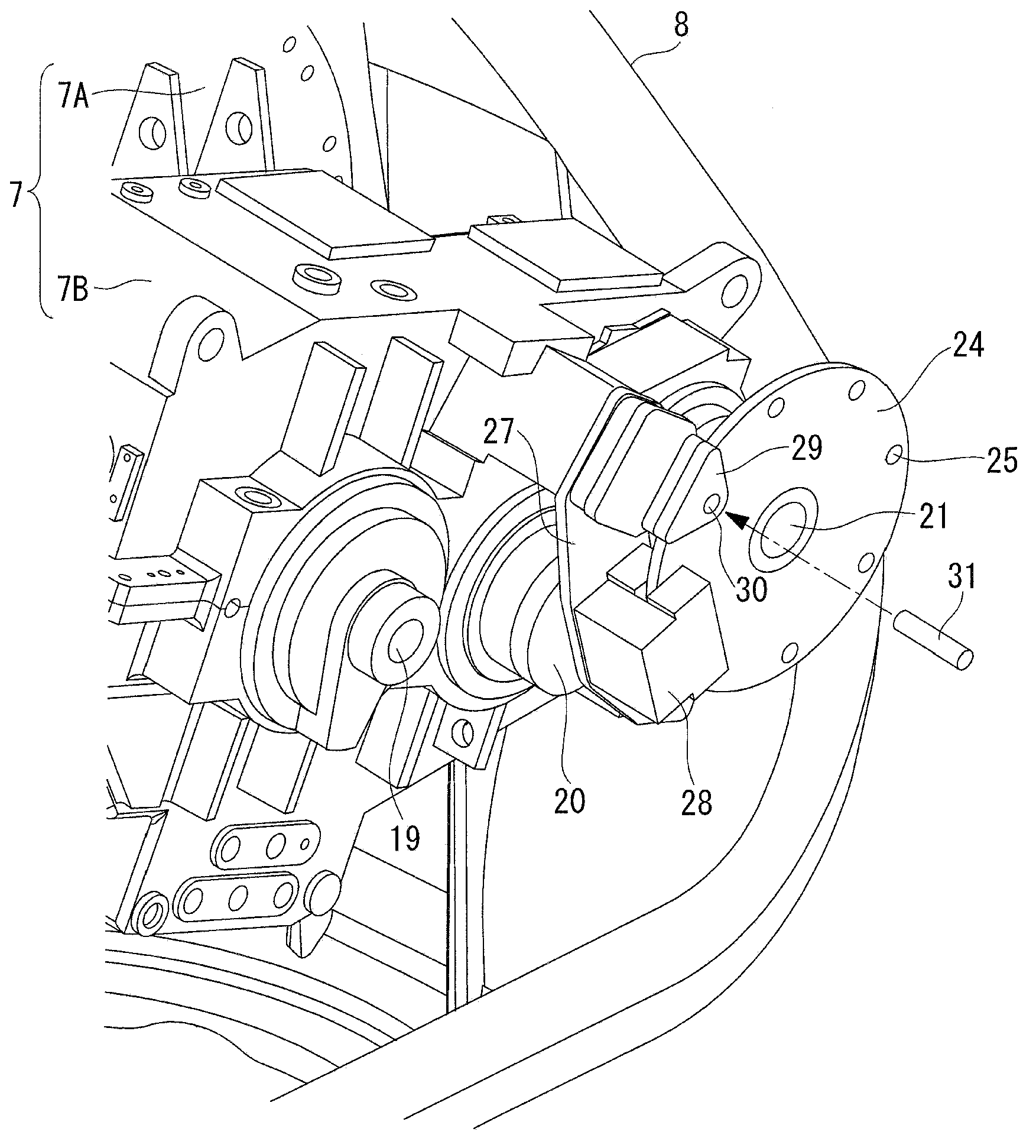

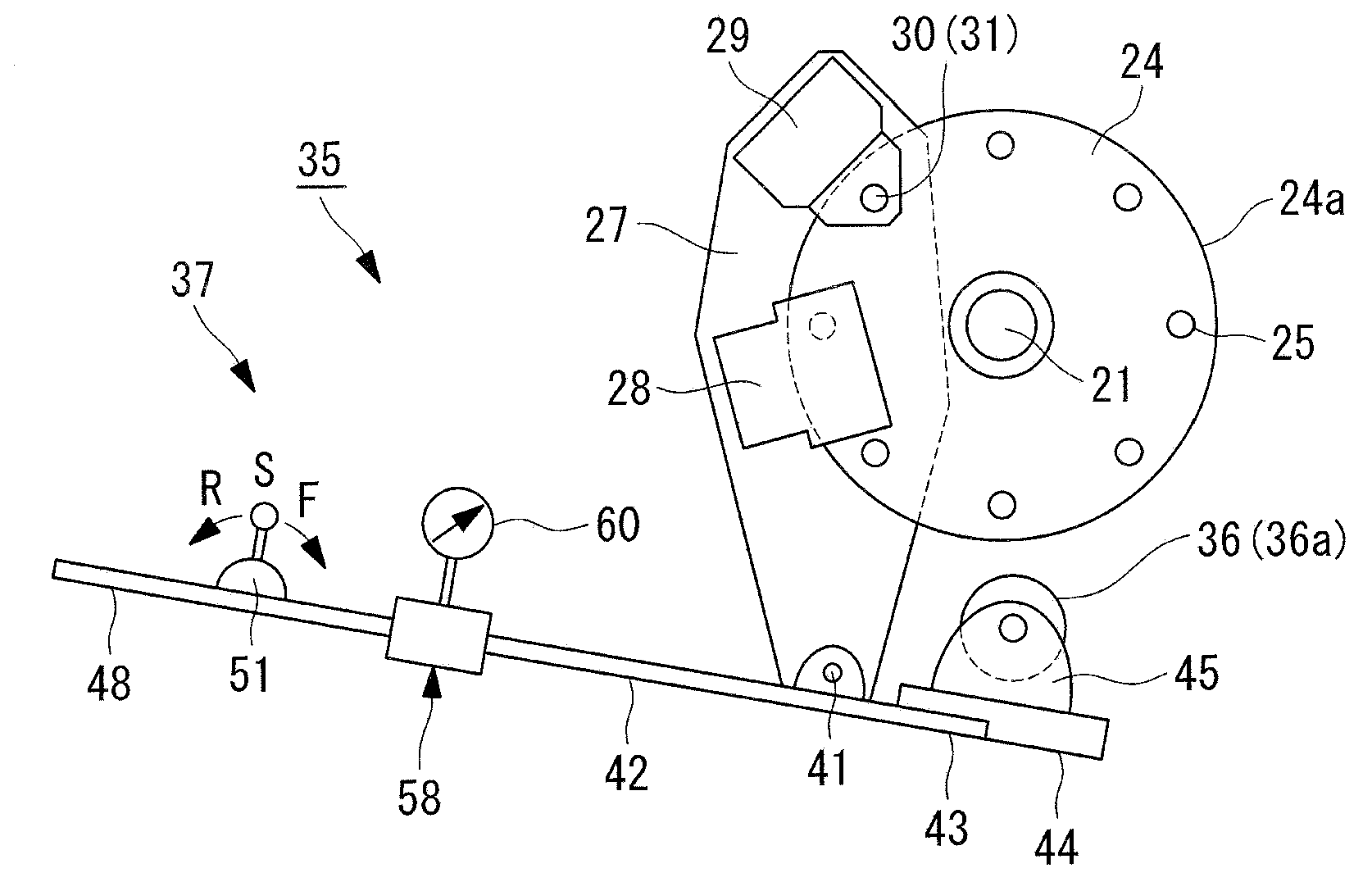

[0046] The speed increaser 7 is housed in a highly rigid steel pod deck 8 at the upper end of the tower 3 together with a main bearing (not shown) that pivotally supports the main shaft of the windmill rotor blade 5 . It is pivotally supported so that it can rotate freely. In addition, a generator installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com