Method and device for processing wafer sandwich blocks

A wafer and conveying device technology, applied in the direction of forming/molding baked waffles, etc., can solve the problems of limited conveying power, high acceleration force of wafers, and small mechanical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

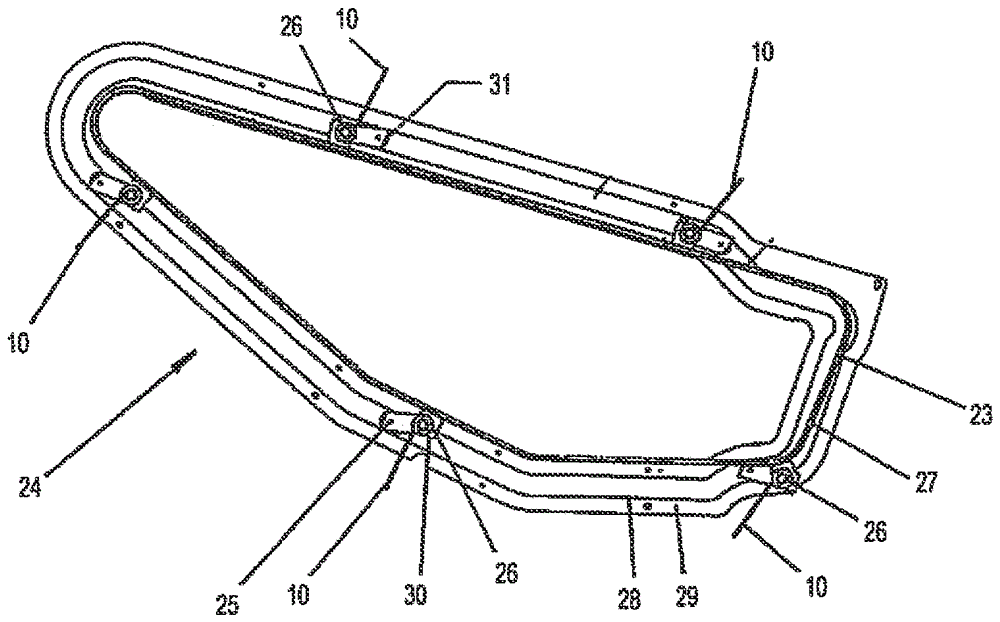

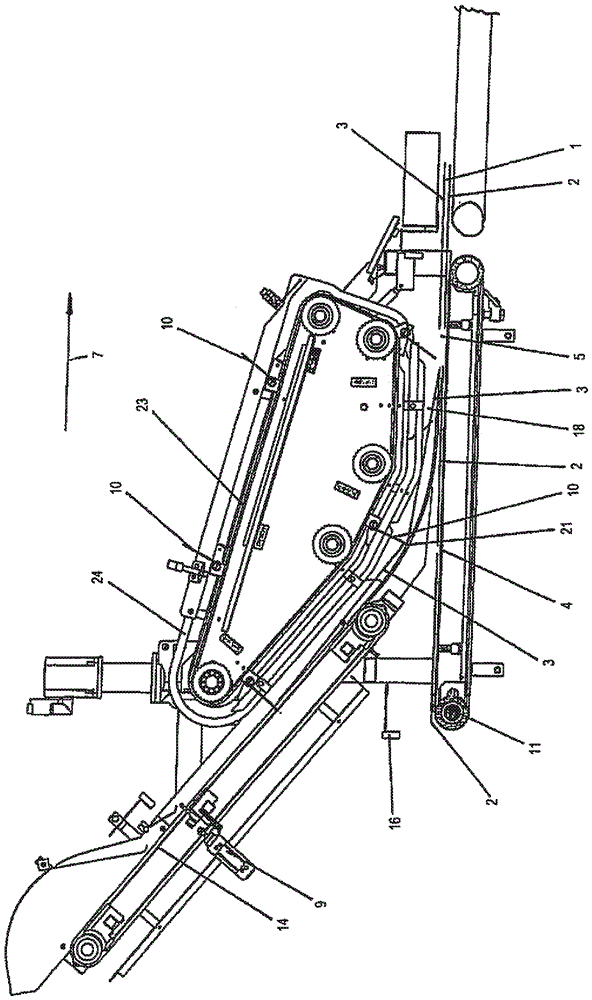

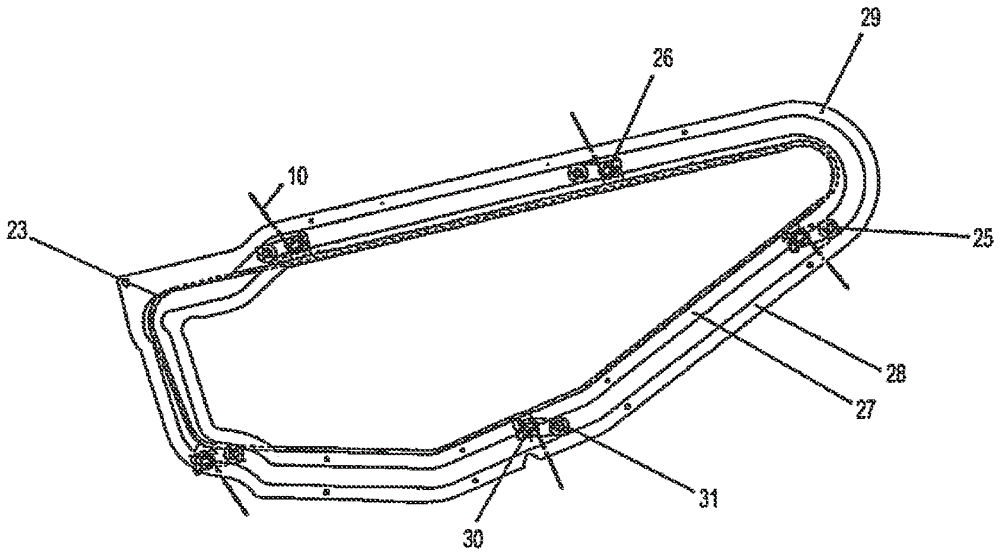

[0016] figure 1 A device according to the invention for processing multi-layered wafer pieces filled with a spread, such as cream, is shown, with a first conveyor surface 4, which in the present embodiment comprises a first conveyor device 11 and a second conveyor device 12. Furthermore, a second conveying surface 6 is provided, which includes a third conveying device 13 and a fourth conveying device 14 . The second conveying surface comprises a raised section extending substantially parallel to the first conveying surface, an inclined section extending substantially from the raised section to the stacking location 5 and an entry point 18 which makes the second conveying surface substantially gradually The first conveying surface is approached linearly or wedge-shaped. Furthermore, a fifth conveying device 15 is provided. It includes positioning elements 10 which are arranged substantially in motion along the second conveying plane. Furthermore, a detector 16 is provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com