Hybrid energy feedback type direct-current traction power supply device and control method

A technology of DC traction and power supply device, which is applied in the direction of converting irreversible AC power input into DC power output, electrical components, and systems for storing electrical energy, etc. The effect of reducing space requirements, eliminating device size constraints, and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

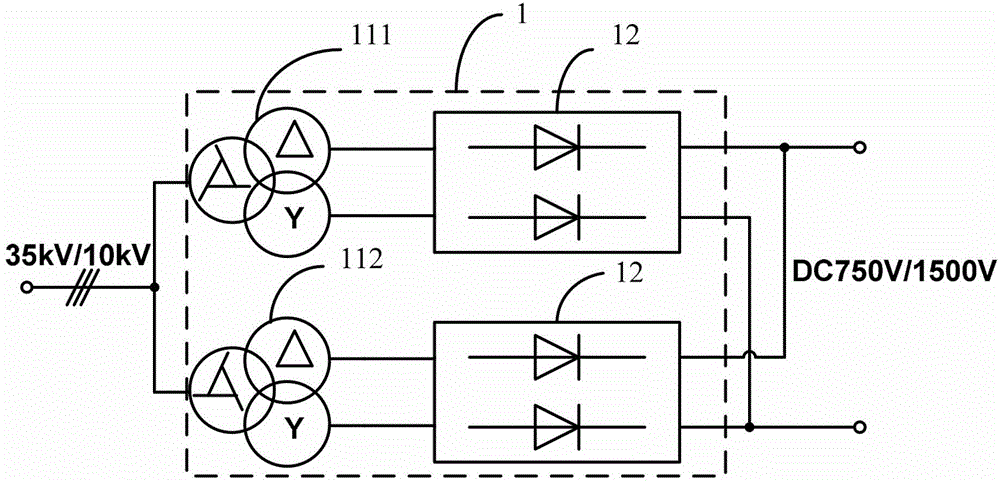

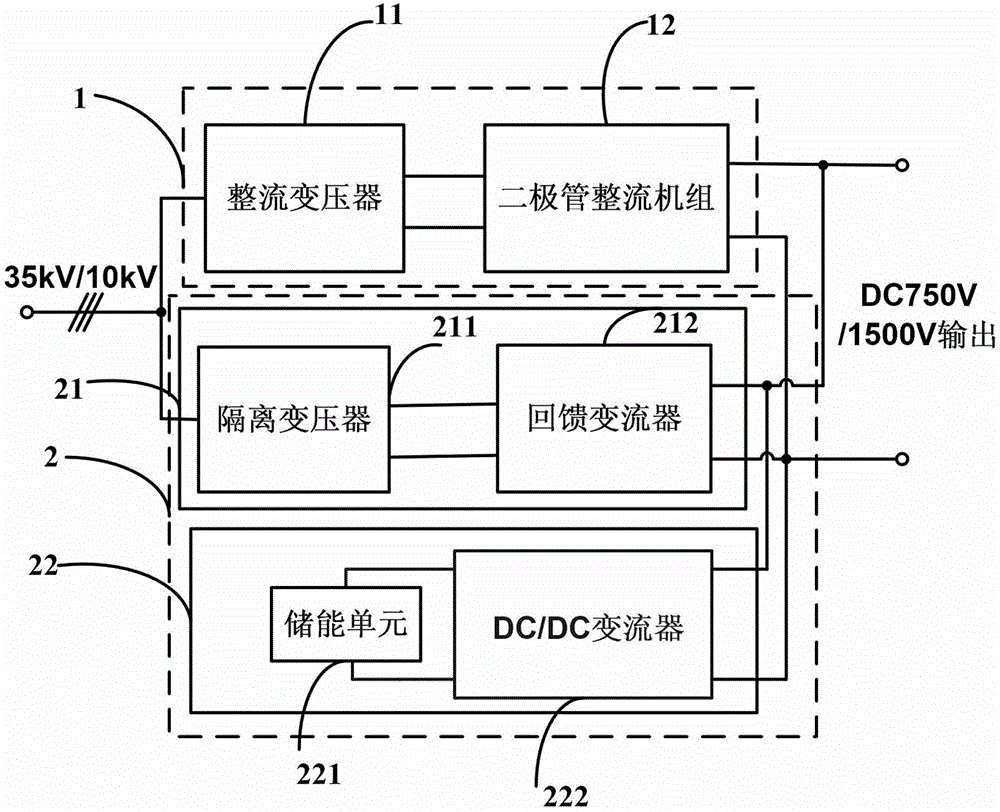

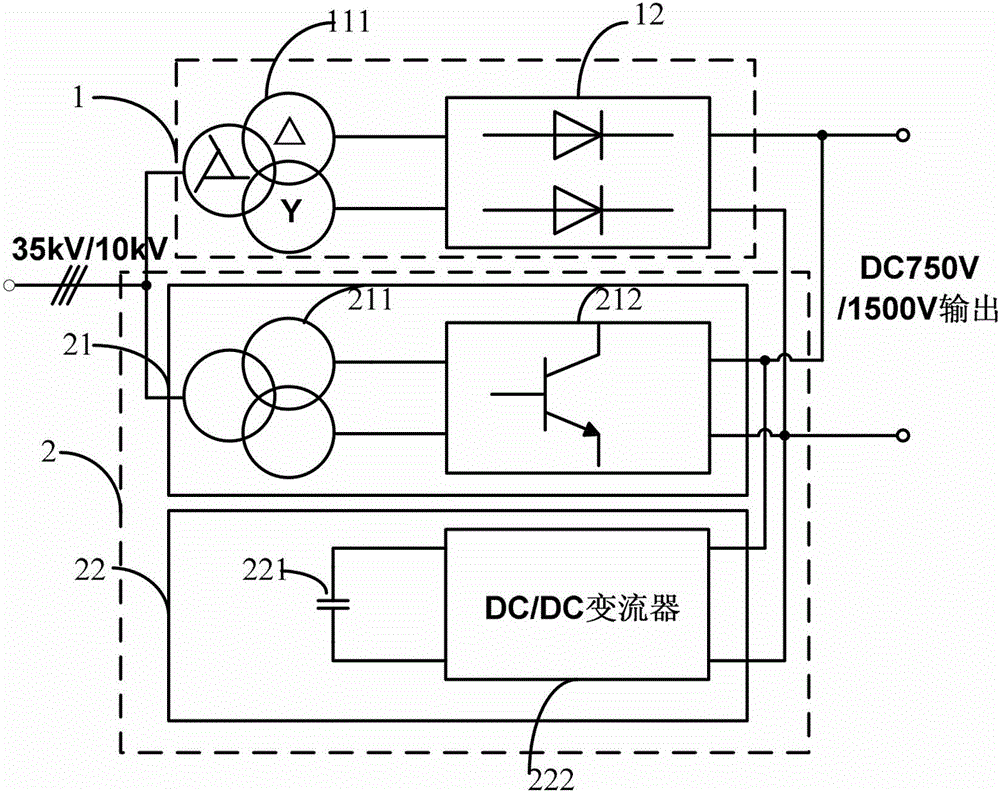

[0040] Such as figure 2 As shown, the structure of the hybrid energy-fed DC traction power supply device of the present invention includes a diode rectification assembly 1 and a braking energy processing assembly 2. The diode rectification assembly 1 includes a rectification transformer 11 and a diode rectification unit 12. The diode rectification assembly 1 and the braking energy Processing components 2 are connected in parallel. The braking energy processing component 2 includes a feedback branch 21 and an energy storage branch 22 connected in parallel, and the AC side of the diode rectification component 1 and the feedback branch 21 are respectively connected to the AC power supply 35kv / 10kV end, and the DC side is respectively connected to the DC output DC7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com