High-speed automatic adhesive coating machine for lithium ion battery core

A technology of lithium ion battery and laminating machine, applied in the field of laminating machine, can solve the problems of reducing production efficiency, a large number of manpower, increasing the labor intensity of staff, etc., to achieve the effect of improving the degree of automation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

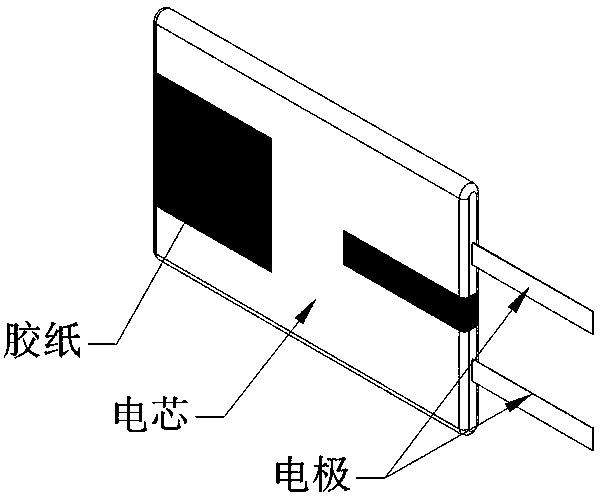

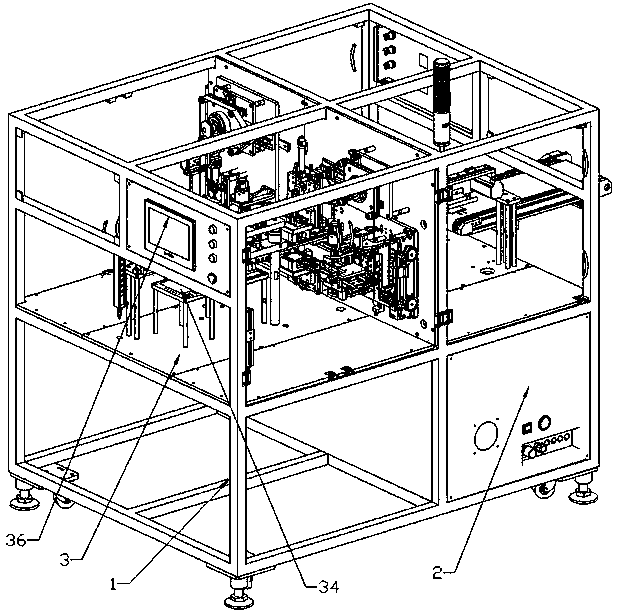

[0027] Such as Figures 3 to 12 As shown, the present invention includes a frame 1 on which an electric control part 2 , a working platform 3 and a vertical plate 4 are arranged. A rubber encapsulation device is arranged on the vertical plate 4 . The number of said encapsulating devices is two sets. One set of rubber covering devices has a larger width of rubber covering, and the other set of rubber covering devices has a smaller width of rubber covering. On the end of the cell with electrodes and between the two electrodes. When working, the glued paper on the same cell can complete the glue wrapping action at the same time or independently. Each set of the adhesive device includes an adhesive paper output part a, an adhesive part b and a cell clamping part c, and the adhesive paper output part a, the adhesive part b and the cell clamping part c Connect end to end in sequence, the adhesive tape output part a outputs the adhesive tape, and after the adhesive tape is pulled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com