Organic light-emitting device and preparation method thereof

An electroluminescent device and luminescence technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of easy luminescence quenching of light-emitting devices, thin electron injection layer thickness, and difficult process control. Achieve the effects of reducing the probability of luminescence quenching, reducing potential barriers, and improving luminescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

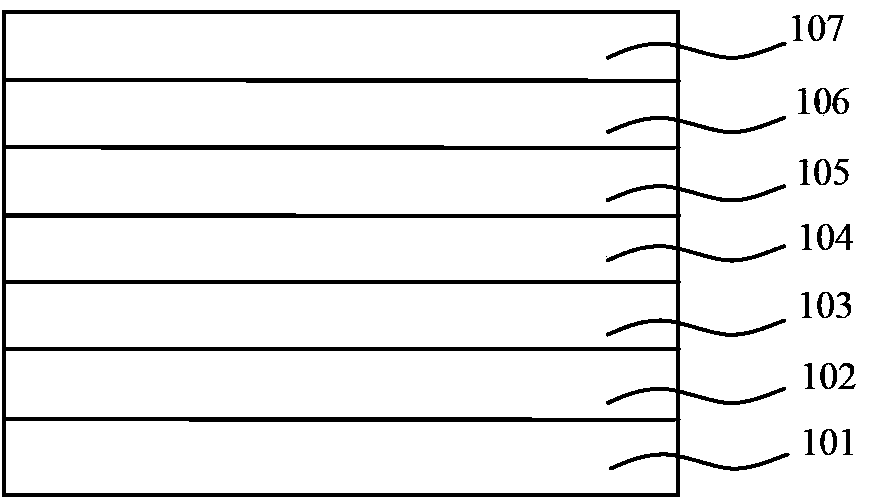

[0071] A method for preparing an organic electroluminescent device, comprising the following steps:

[0072] (1) Conductive anode substrate pretreatment

[0073] Clean the ITO substrate with a thickness of 100nm with detergent, deionized water, acetone, and ethanol in sequence, for 5 minutes each time, then stop for 5 minutes, and repeat 3 times respectively; then dry it in an oven for use; Thereafter, it was treated with oxygen plasma for 10 minutes at a power of 35W.

[0074] (2) Preparation of hole injection layer, hole transport layer, green light emitting layer, electron transport layer, electron injection layer

[0075] Place the pretreated ITO substrate in a vacuum chamber and evacuate to 1×10 -5 Pa, then MoO 3 Doped into N,N'-diphenyl-N,N'-di(1-naphthyl)-1,1'-biphenyl-4,4'-diamine (NPB) according to the doping mass fraction of 30wt% As a hole injection layer, with A hole injection layer with a thickness of 12.5nm is evaporated on the ITO substrate at an evaporati...

Embodiment 2

[0084] A method for preparing an organic electroluminescent device, comprising the following steps:

[0085] (1) Conductive anode substrate pretreatment

[0086] The FTO substrate with a thickness of 100nm was ultrasonically cleaned with detergent, deionized water, acetone, and ethanol in sequence. Each time, it was cleaned for 5 minutes, and then stopped for 5 minutes. Repeated 3 times respectively; and then dried in an oven for use; Thereafter, it was treated with oxygen plasma for 10 minutes at a power of 35W.

[0087] (2) Preparation of hole injection layer, hole transport layer, green light emitting layer, electron transport layer, electron injection layer

[0088] Place the pretreated FTO substrate in a vacuum chamber and evacuate to 1×10 -5 Pa, then WO 3 Doped into 4,4',4"-tris(carbazol-9-yl)triphenylamine (TCTA) as a hole injection layer according to the doping mass fraction of 25wt%, to A hole injection layer with a thickness of 10nm is evaporated on the FTO subs...

Embodiment 3

[0097] A method for preparing an organic electroluminescent device, comprising the following steps:

[0098] (1) Conductive anode substrate pretreatment

[0099] The AZO substrate with a thickness of 100nm was ultrasonically cleaned with detergent, deionized water, acetone, and ethanol in sequence. Each time, it was cleaned for 5 minutes, and then stopped for 5 minutes. Repeated 3 times respectively; and then dried in an oven for use; Thereafter, it was treated with oxygen plasma for 10 minutes at a power of 35W.

[0100] (2) Preparation of hole injection layer, hole transport layer, green light emitting layer, electron transport layer, electron injection layer

[0101] Place the pretreated AZO substrate in a vacuum chamber and evacuate to 5×10 -5 Pa, then V 2 o 5 Doped into 4,4'-bis(9-carbazole)biphenyl (CBP) as a hole injection layer according to the doping mass fraction of 35wt%, to A hole injection layer with a thickness of 15nm is evaporated on the AZO substrate at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com