Organic light-emitting device and preparation method thereof

An electroluminescence device and luminescence technology, applied in the direction of electric solid-state devices, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of light-emitting devices such as easy luminescence quenching, difficult process control, and poor performance, and achieve Good performance complementation and charge balance, improved thermal stability, and improved luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

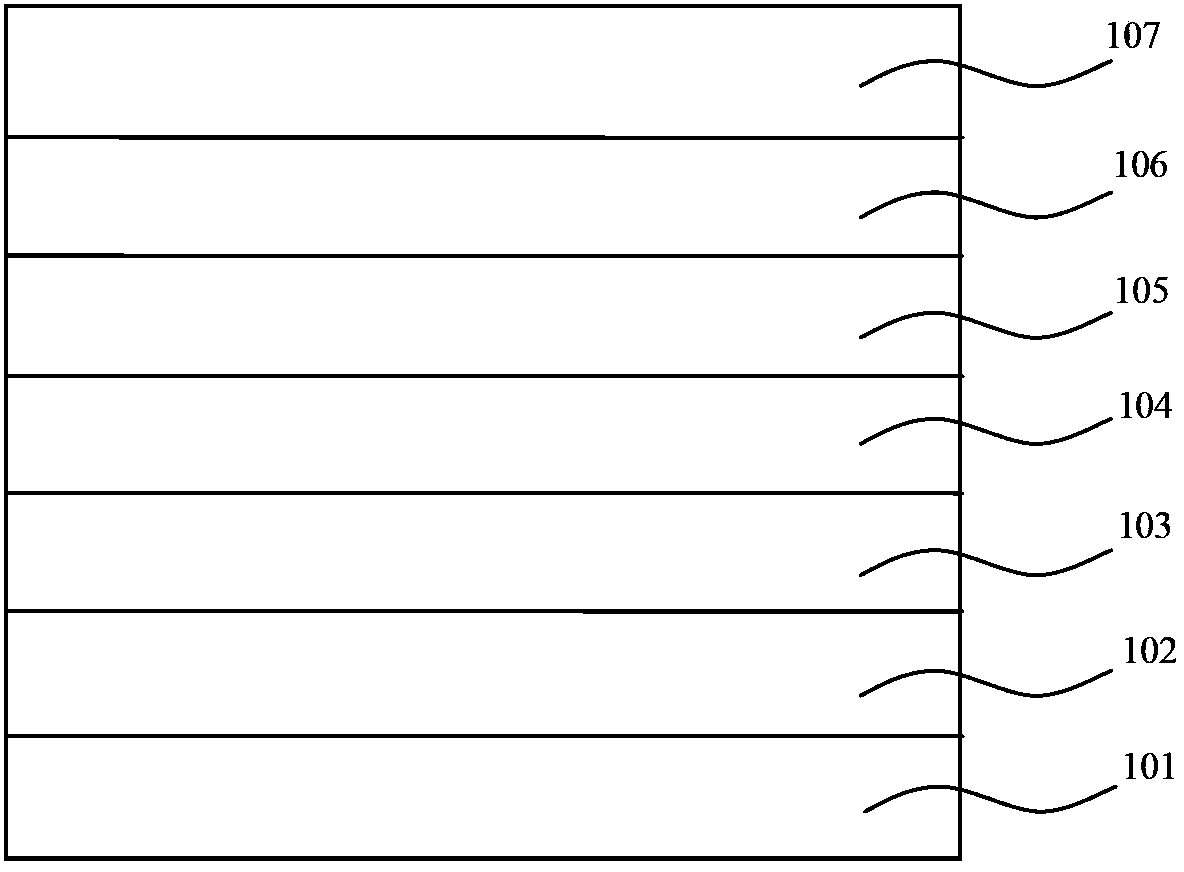

[0078] A method for preparing an organic electroluminescent device, comprising the following steps:

[0079] (1) Pre-treatment of ITO glass substrates: cleaning with detergent → cleaning with deionized water → cleaning with acetone → cleaning with ethanol, all of which are cleaned with an ultrasonic cleaning machine. Each washing is carried out for 5 minutes, stopped for 5 minutes, and repeated 3 times respectively. method, and then dry it in an oven for use; the cleaned ITO glass also needs to be subjected to surface activation treatment to increase the oxygen content on the ITO surface and improve the work function of the ITO surface; the ITO thickness is 100nm;

[0080] (2) Preparation of the hole injection layer: the MoO 3 Doped into NPB as a hole injection layer, the doping mass fraction is 30wt%, the thickness is 12.5nm, and the vacuum degree is 1×10 -5 Pa, evaporation rate

[0081] (3) Preparation of hole transport layer: using NPB; vacuum degree 1×10 -5 Pa, evapor...

Embodiment 2

[0088] A method for preparing an organic electroluminescent device, comprising the following steps:

[0089] (1) Pre-treatment of ITO glass substrates: cleaning with detergent → cleaning with deionized water → cleaning with acetone → cleaning with ethanol, all of which are cleaned with an ultrasonic cleaning machine. Each washing is carried out for 5 minutes, stopped for 5 minutes, and repeated 3 times respectively. method, and then dry it in an oven for use; the cleaned ITO glass also needs to be subjected to surface activation treatment to increase the oxygen content on the ITO surface and improve the work function of the ITO surface; the ITO thickness is 100nm;

[0090] (2) Preparation of the hole injection layer: the WO 3 Doped into TCTA as a hole injection layer, the doping mass fraction is 25wt%, the thickness is 10nm, and the vacuum degree is 5×10 -5 Pa, evaporation rate

[0091] (3) Preparation of hole transport layer: using TCTA; vacuum degree 5×10 -5 Pa, evapora...

Embodiment 3

[0098] A method for preparing an organic electroluminescent device, comprising the following steps:

[0099] (1) Pre-treatment of ITO glass substrates: cleaning with detergent → cleaning with deionized water → cleaning with acetone → cleaning with ethanol, all of which are cleaned with an ultrasonic cleaning machine. Each washing is carried out for 5 minutes, stopped for 5 minutes, and repeated 3 times respectively. method, and then dry it in an oven for use; the cleaned ITO glass also needs to be subjected to surface activation treatment to increase the oxygen content on the ITO surface and improve the work function of the ITO surface; the ITO thickness is 100nm;

[0100] (2) Preparation of the hole injection layer: the V 2 o 5 Doped into CBP as a hole injection layer, the doping mass fraction is 35wt%, the thickness is 15nm, and the vacuum degree is 5×10 -5 Pa, evaporation rate

[0101] (3) Preparation of hole transport layer: using CBP; vacuum degree 5×10-5Pa, evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous efficiency | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com