Bijection type reflecting solder strip

A reflective welding tape and beam-type technology, applied in photovoltaic power generation, electrical components, circuits, etc., to achieve high conversion efficiency, reduce conversion efficiency loss, and increase light intensity and area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

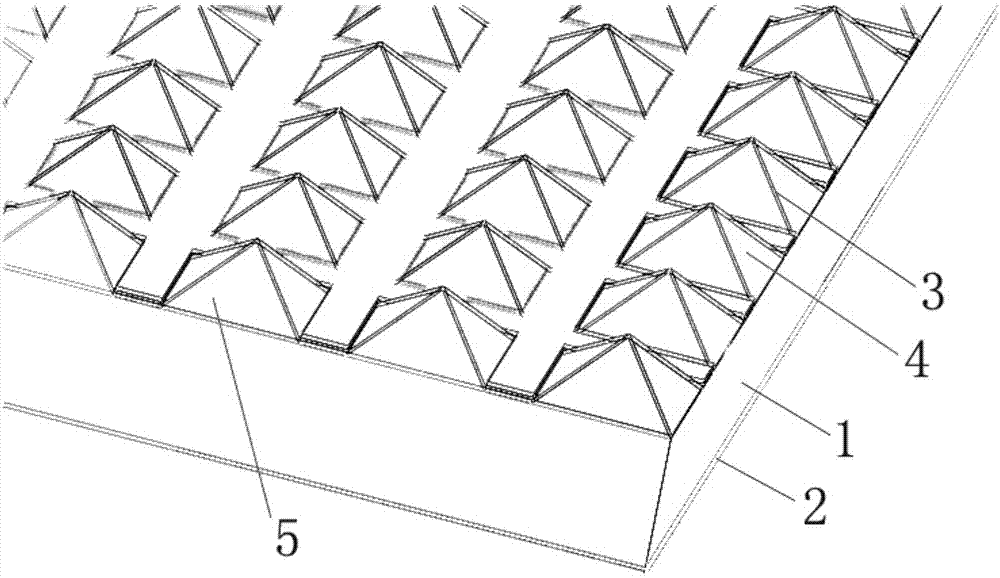

[0012] Such as figure 1 As shown, it includes a film substrate 1, a sticking film layer 2, a metal layer 3, a reflective surface 4, a protrusion 5, and the like.

[0013] Such as figure 1 As shown, a through-beam type reflective soldering tape of the present invention comprises a film base 1, the bottom surface of the film base 1 is fixed with an adhesive film layer 2, and the top surface of the film base 1 has a number of integrally connected and evenly distributed with the film base 1. Protrusions 5, each of the protrusions 5 is a regular pyramid structure, a layer of metal layer 3 is attached to the surface of the regular pyramid protrusions 5 and the upper plane of the film substrate 1, and the surface of the metal layer 3 forms a pair of reflective surface 4.

[0014] The film substrate 1 has a thickness of 0.01mm-0.5mm and a width of 1mm-50mm.

[0015...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com