Photovoltaic reflecting light reflection film

A reflective film and photovoltaic technology, applied in the direction of photovoltaic power generation, semiconductor devices, electrical components, etc., can solve the problems of affecting the normal power generation of light energy, low light energy reception rate, and poor energy conversion effect, so as to reduce the conversion efficiency Effects of loss, high conversion efficiency, increased light intensity and area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] (1) The first group selects the parameters of each structure as follows:

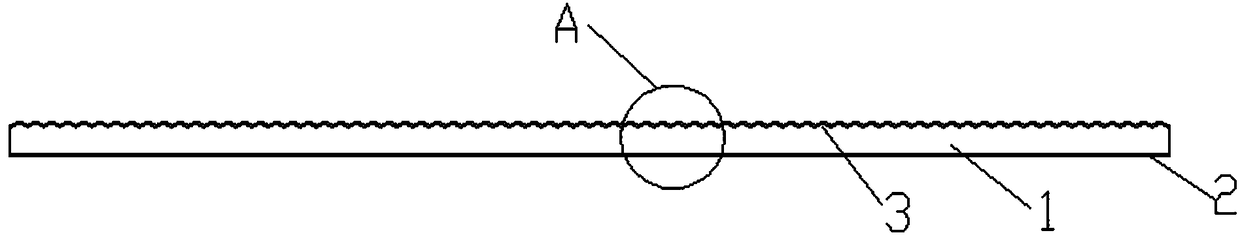

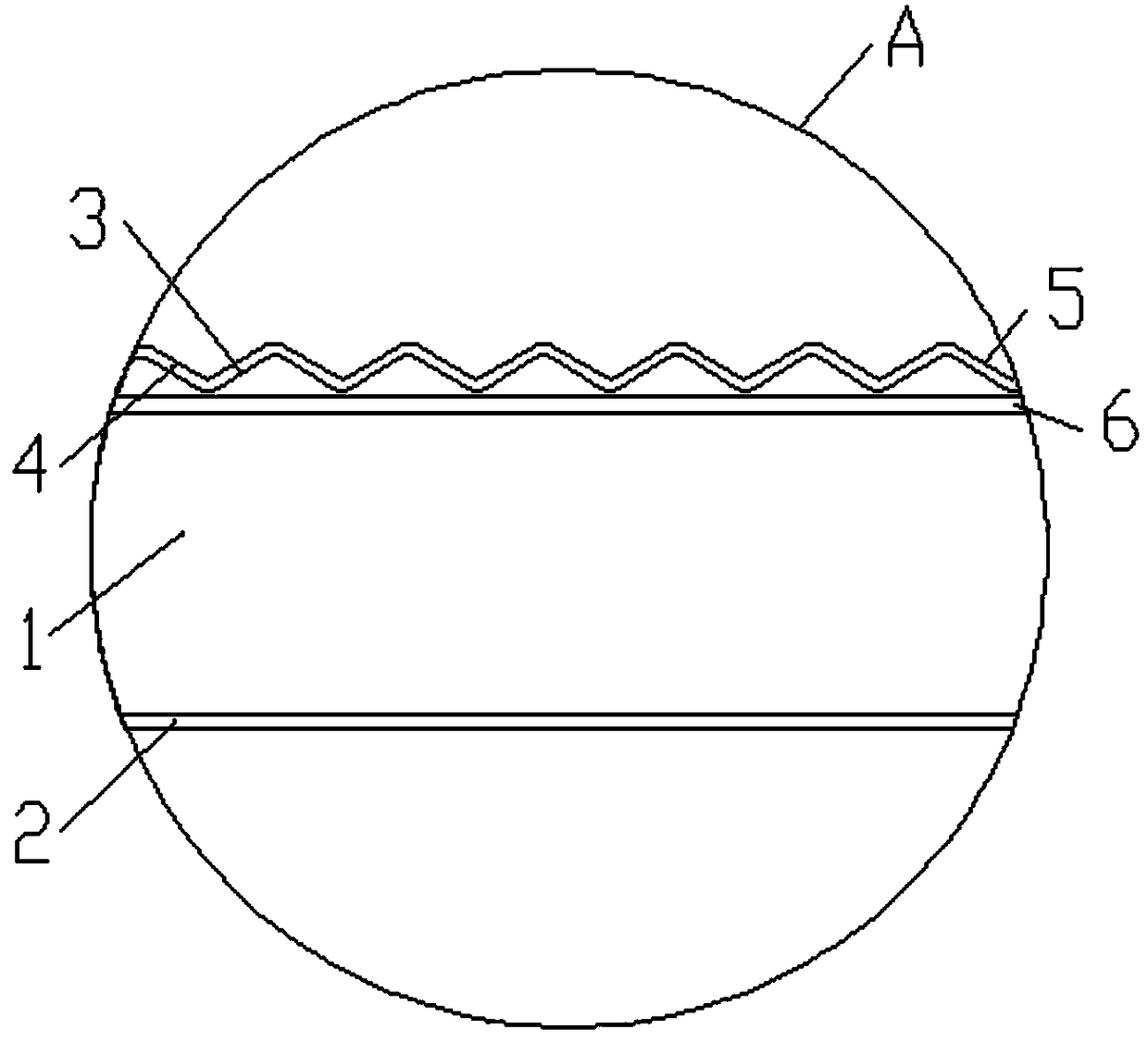

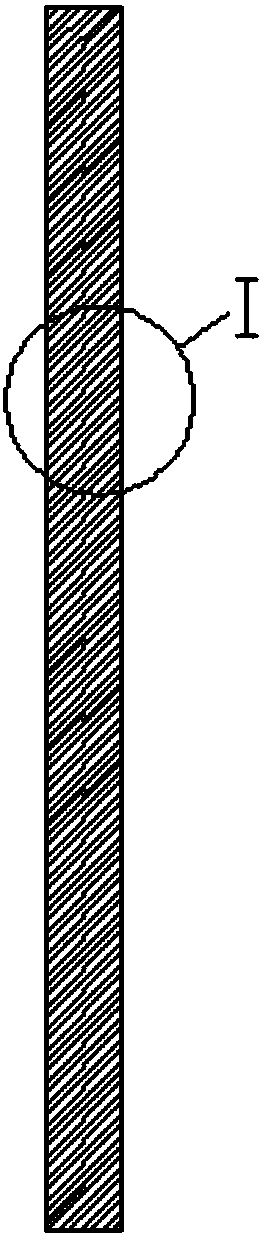

[0026] The thickness, width and height of the film substrate 1 are 0.01mm, 1mm and 0.09mm respectively;

[0027] The thickness of the adhesive film layer 2 is 0.01mm;

[0028] The included angle at the upper end of the UV curing triangular bump 3 is 110°;

[0029] The UV curing triangular bumps 3 are arranged in an isosceles triangle that can be shifted to the left by 40° from the longitudinal horizontal plane;

[0030] The thickness of the metal reflective refraction layer 4 is 0.0001 mm.

[0031] (2) The second group selects the parameters of each structure specifically as follows:

[0032] The thickness, width and height of the film substrate 1 are 0.011mm, 25.5mm and 0.09mm respectively;

[0033] The thickness of the adhesive film layer 2 is 0.55mm;

[0034] The included angle at the upper end of the UV curing triangular bump 3 is 120°;

[0035] The UV curing triangular bumps 3 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com