Automatic skip-stop detection system

A detection system, a technology of jumping goods, applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of unable to detect the production line, products cannot be detected, low detection accuracy, etc., to improve the detection accuracy and detection efficiency, improve detection efficiency and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

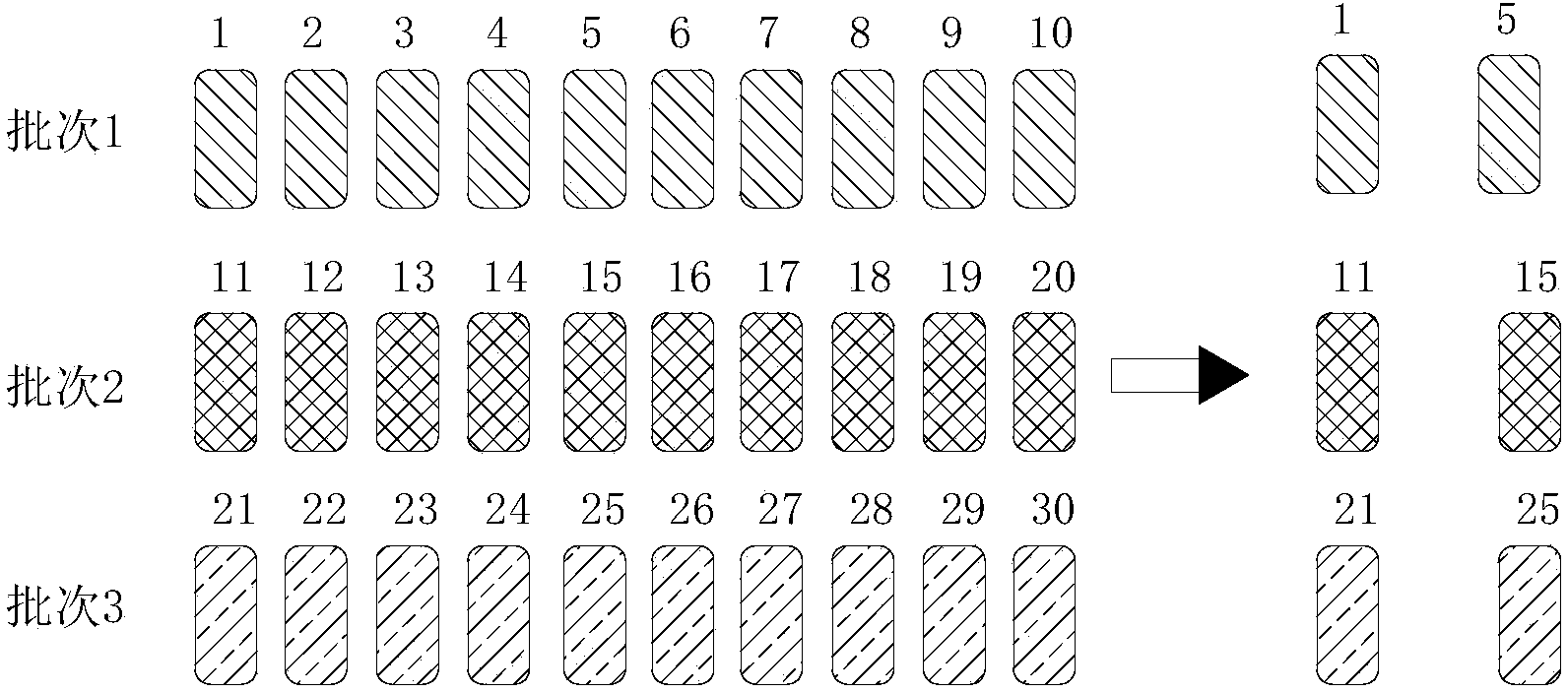

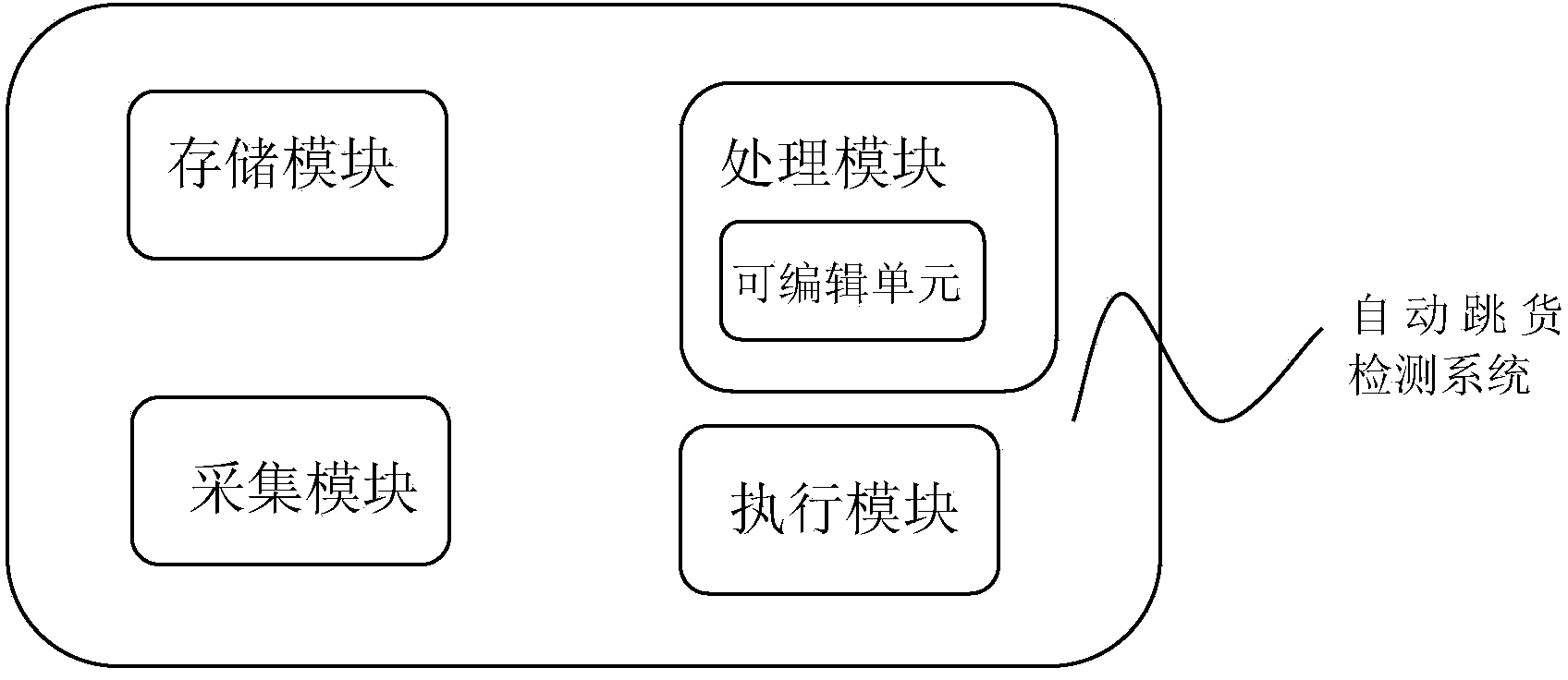

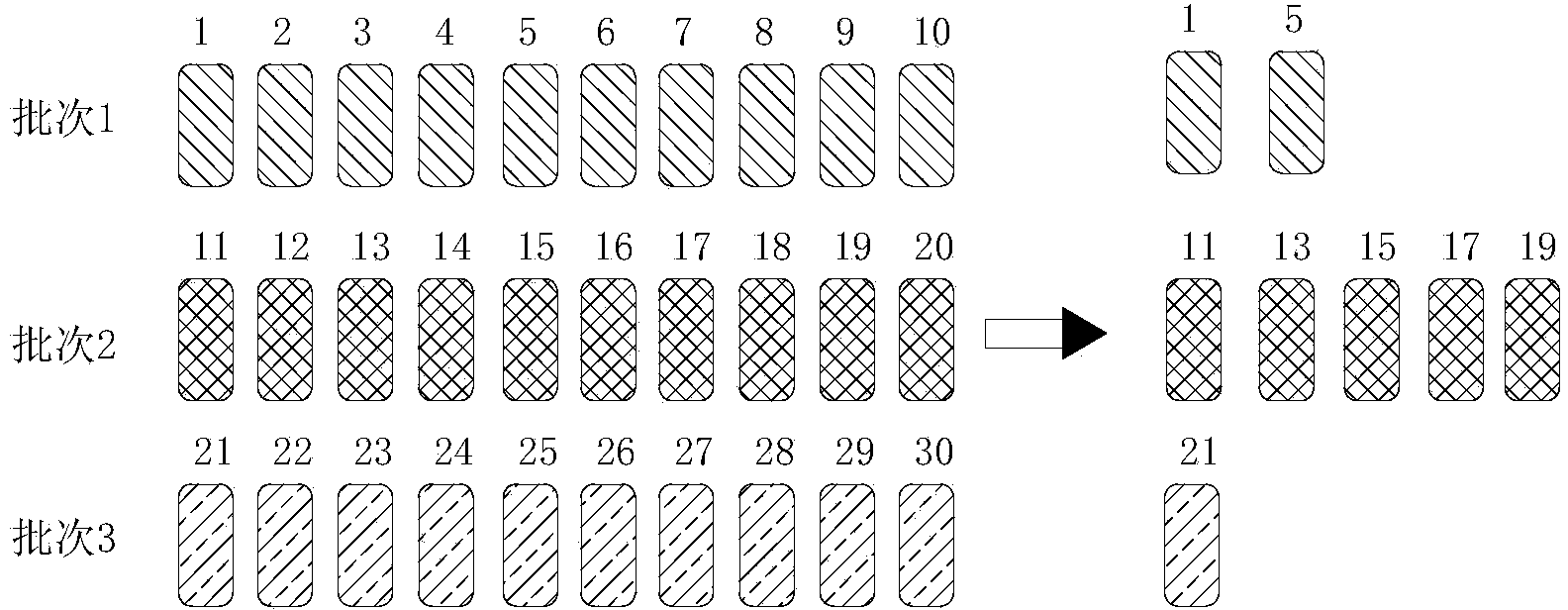

[0023] The invention discloses an automatic skipping detection system, which detects multiple batches of products at any detection station, such as figure 2 As shown, the system includes a storage module, an acquisition module, a processing module and an execution module;

[0024] The storage module stores all production machine information on the production line;

[0025] The acquisition module is used to scan each batch of products passing through the site and obtain the machine information corresponding to the batch of products through the storage module; specifically, the acquisition module scans some products of each batch of products flowing through the site, and Compare with the information of each machine stored in the storage module to obtain the machine from which the batch of products came from;

[0026] The processing module selects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com