Mechanical delay switch

A delay switch, mechanical technology, applied in the field of mechanical processing and manufacturing, can solve the problems of delay switches that are not equipped with software control and cannot manufacture electronic timers, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

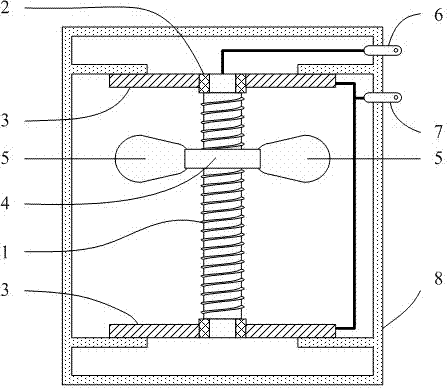

[0016] The invention relates to a mechanical delay switch. One of its specific implementations is as figure 1 shown; in order to facilitate the representation of the internal structure, figure 1 It shows the schematic diagram of the structure of the mechanical delay switch after cutting the insulating shell and the chassis. The mechanical delay switch includes an insulating shell 8, and a delay switch device fixedly arranged in the insulating shell 8. The delay switch device includes a screw 1 and two chassis 3 fixedly installed on both ends of the screw through an insulating member 2. The screw 1 And chassis 3 is copper. The screw 1 is threaded with a nut piece 4, and the nut piece 4 is also made of copper. The outer side of the nut piece 4 is fixedly provided with two counterweights 5 with the same weight evenly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com