Optimal maintaining method for equipment with performance slow degradation

A performance and equipment technology, applied in the field of optimal maintenance of high-reliability equipment, can solve problems such as no failure data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

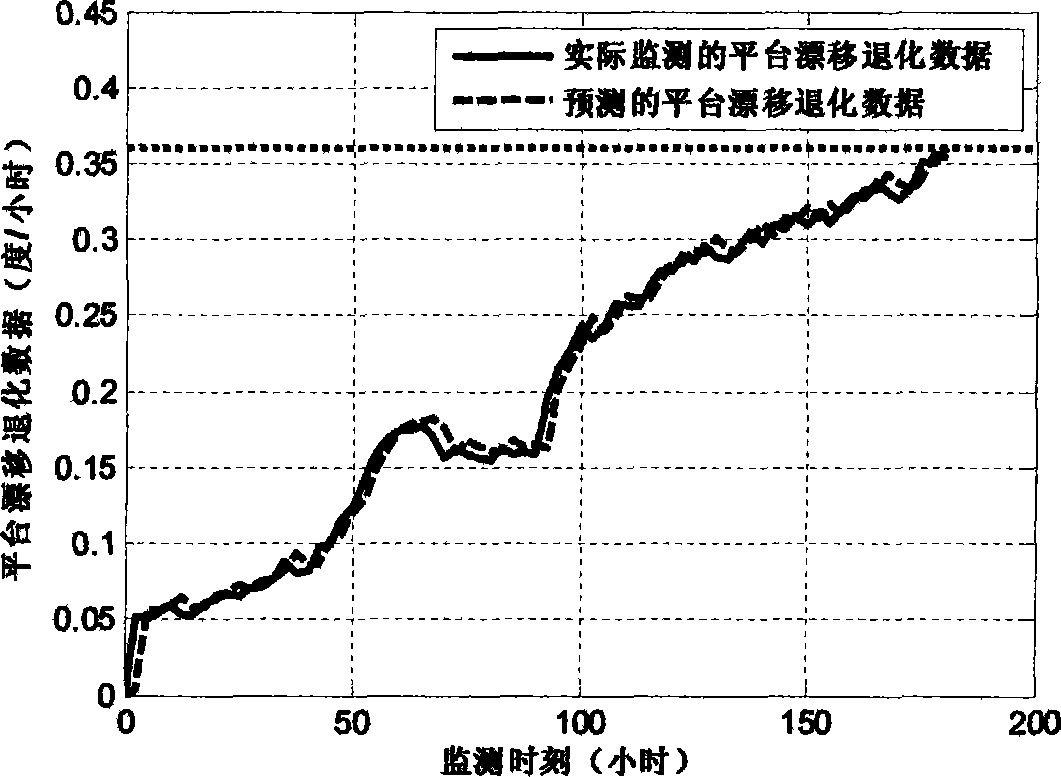

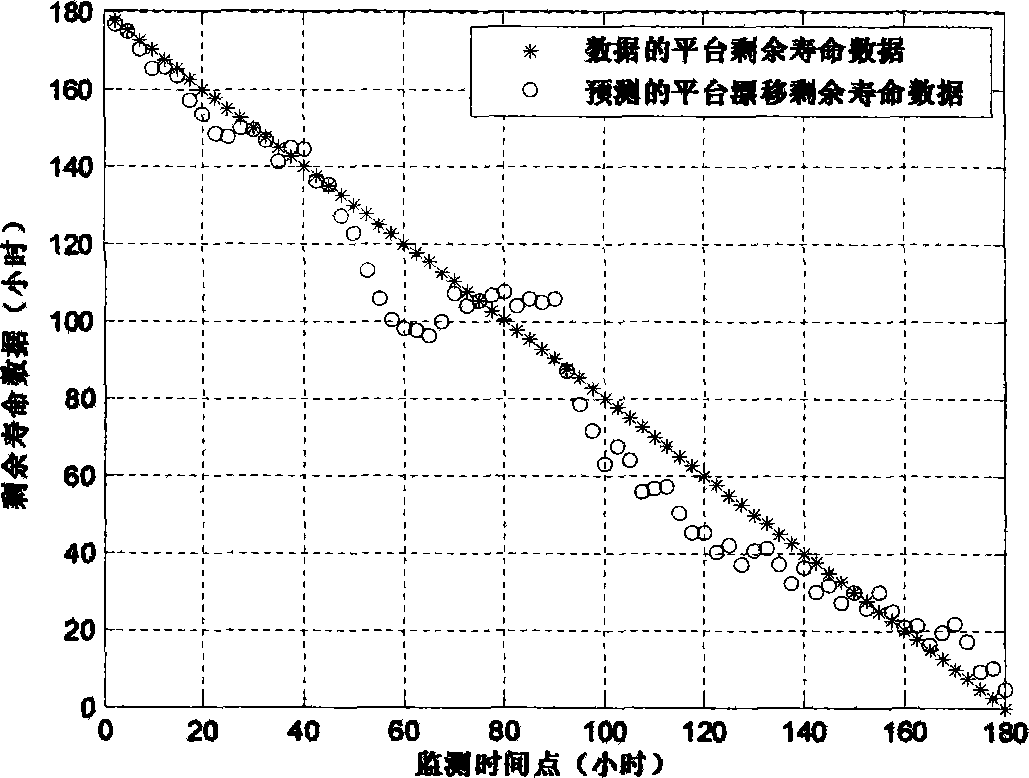

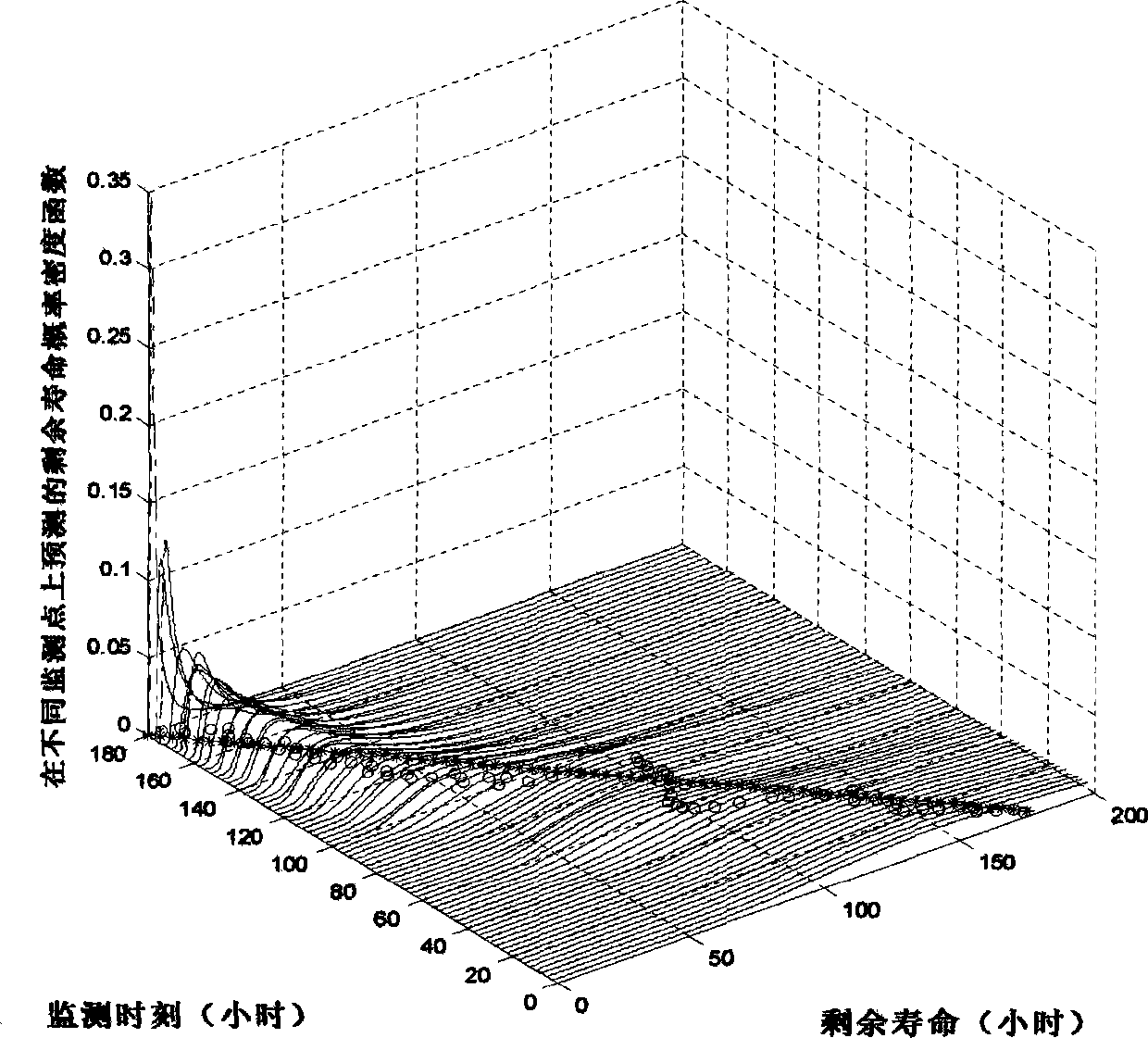

[0051] The optimal maintenance method for complex equipment under the condition of slow performance degradation in the present invention is described by taking the optimal maintenance method of a certain type of gyro platform as an application example, mainly including the following steps:

[0052] Step 1: Construction of dynamic performance degradation database

[0053] The drift error of the gyro platform is an important characteristic parameter that characterizes the performance of the gyro platform. From the drift test data, when the gyro platform is operating normally, the data will fluctuate around a fixed value; when the platform fails, the data usually shows a slow increase. large or sudden change; in the built performance database, the first column is the test time, and the second column is the test data, that is, the drift measurement value of the platform; when the new drift measurement value arrives, the measurement value is directly stored in the test In the datab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com