Operation period underground pipeline pipe diameter measuring method based on ground penetrating radar

A technology of underground pipelines and ground penetrating radar, which is applied in the direction of electromagnetic wave detection to achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

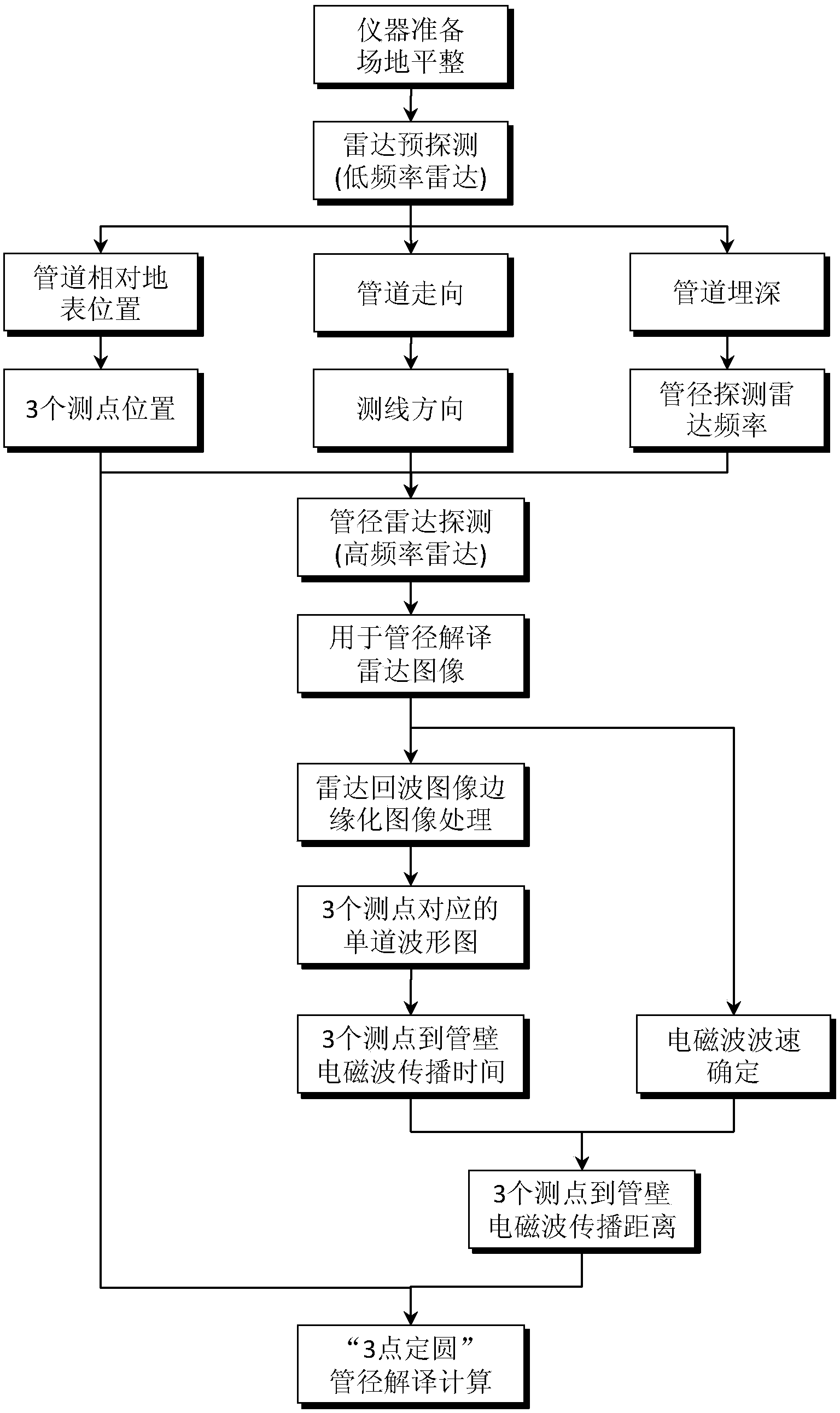

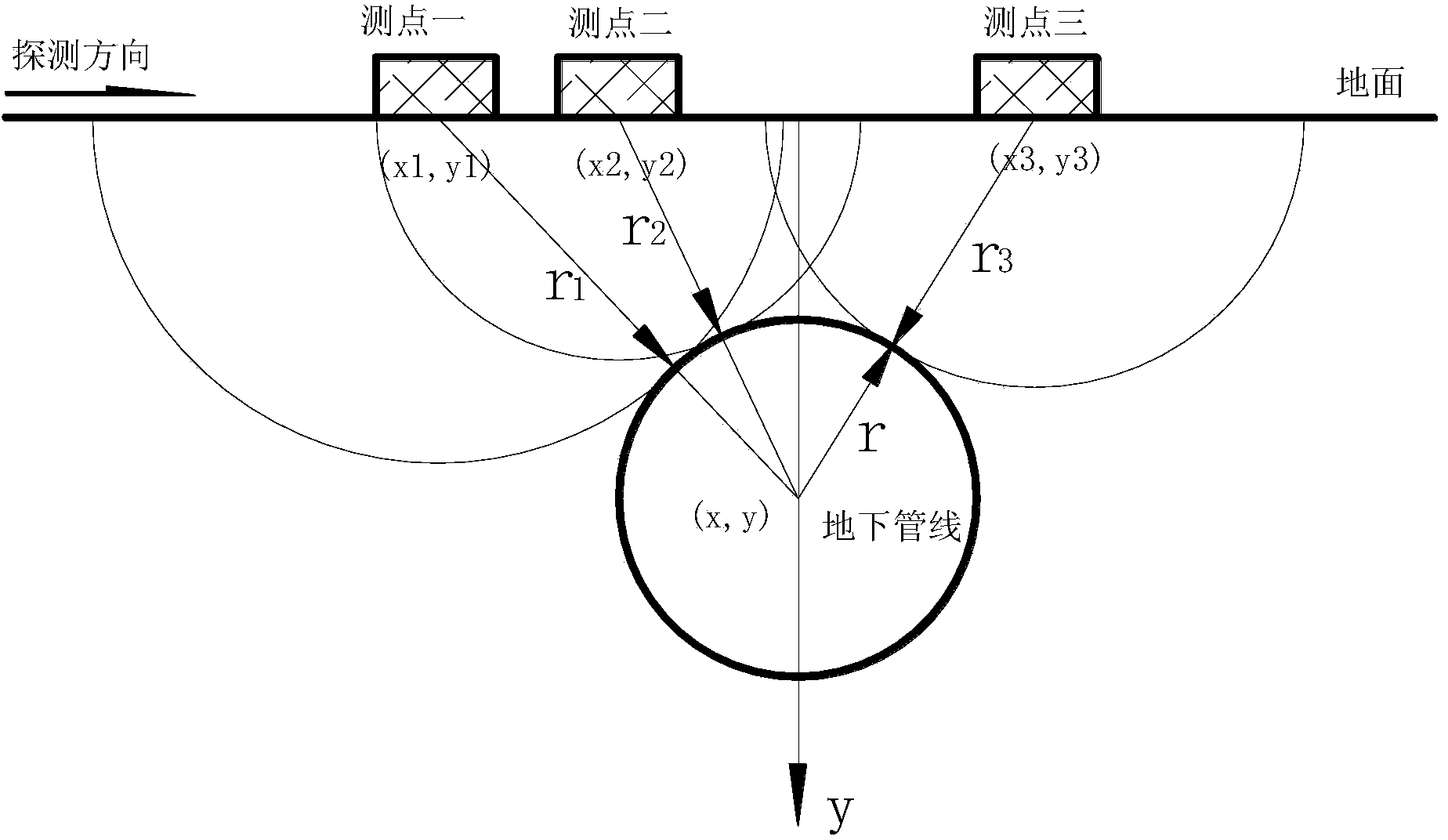

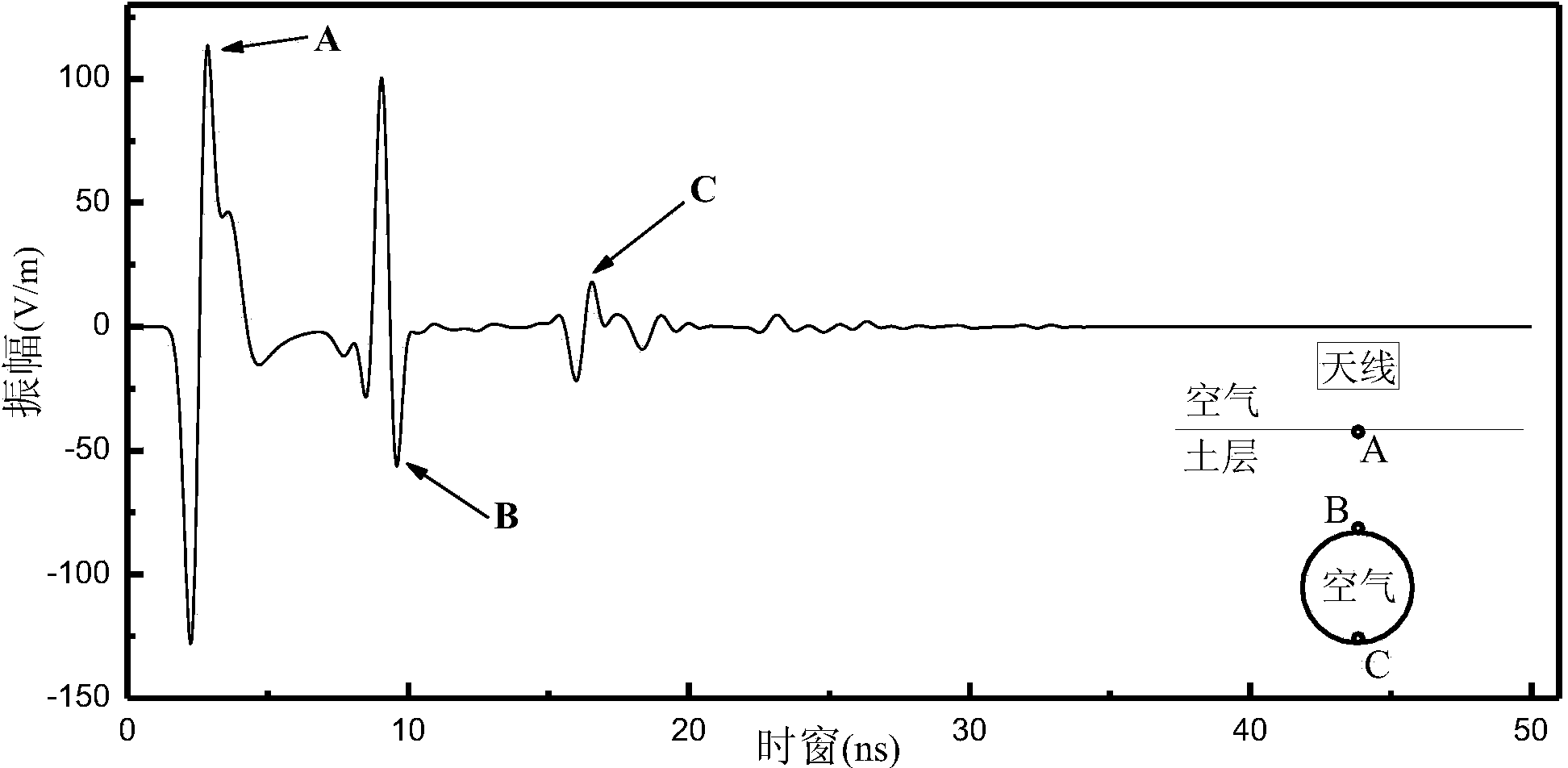

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] To verify the reliability of the new method of measuring the diameter of underground pipelines by "three-point fixed circle", combined with the radar detection project of the sewage pipe network system in Yixing Chemical Industry Park, the buried depth of underground pipelines in the detection area ranges from 0.5 to 4m. The SIR-20 ground penetrating radar developed and produced by GSSI Company of the United States is used for on-site radar detection. According to the corresponding relationship between detection depth and antenna frequency, antennas with center frequencies of 100MHz and 400MHz are selected. Two typical detection sections are selected for introduction and analysis. Table 1 shows the measured pipe diameters of the two typical sections and the error between them and the actual value.

[0029] Table 1 Probing Pipe Diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com