Method for measuring material surface emissivity by virtue of thermal infrared imager rapidly

An infrared thermal imager and surface emissivity technology, applied in the direction of material thermal development, can solve the problems of cumbersome, poor operability, and time-consuming, and achieve the effect of ensuring detection accuracy, improving detection speed, and shortening test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention proposes a rapid measurement method for surface emissivity of complex materials suitable for various infrared thermal imaging cameras. The method only needs to add an auxiliary black box structure to the infrared thermal imaging camera, and then adopts the testing method proposed by the present invention. The emissivity can be measured and calculated quickly on the surface of complex materials composed of multiple materials.

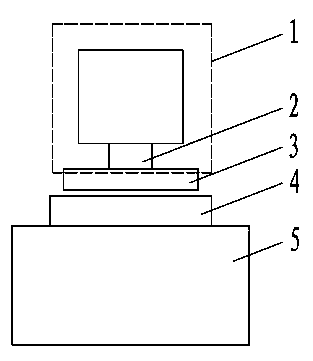

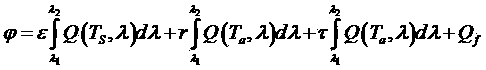

[0047] The method consists of two parts: hardware and software algorithms. The hardware part is: a structure of a black box 3 is added to the lens 2 of the infrared thermal imager 1, and its function is to form a black body, so that all the radiation received by the lens 2 comes from this structure; the algorithm is realized, and the thermal image The response of the instrument to the black box 3, the response of the infrared thermal imager 1 to the measured surface and the response of the infrared thermal imager 1 to the standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com