Reconfigurable leak testing system

A leak test and structure technology, applied in the field of automatic leak test systems for auto parts, can solve problems such as wasting time and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The following description is merely exemplary in nature and is not intended to limit the disclosure, application or uses.

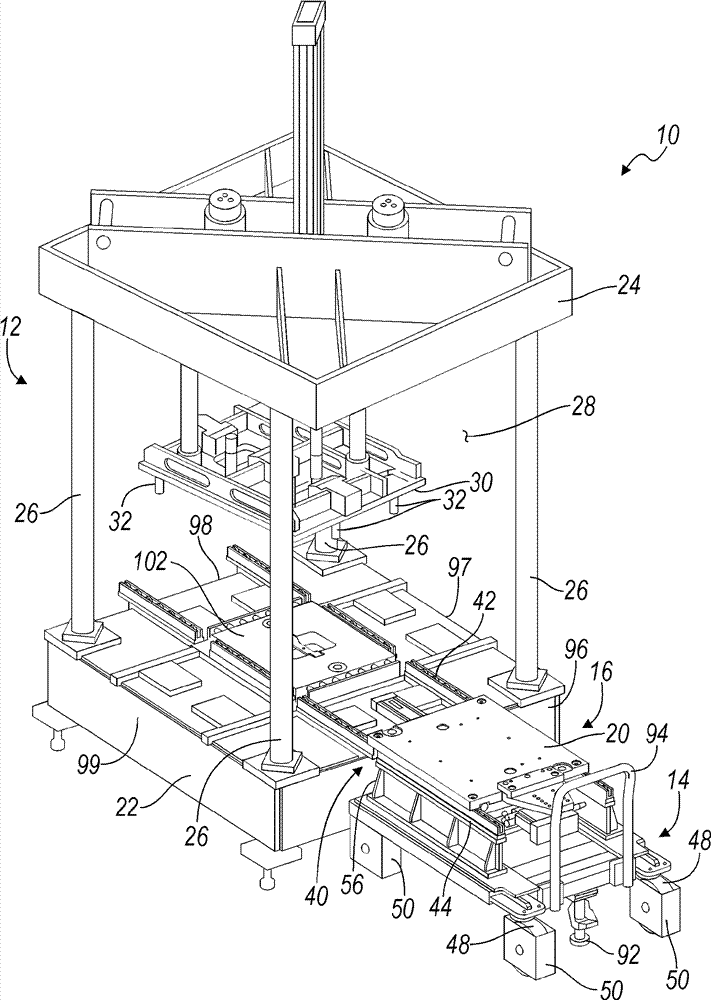

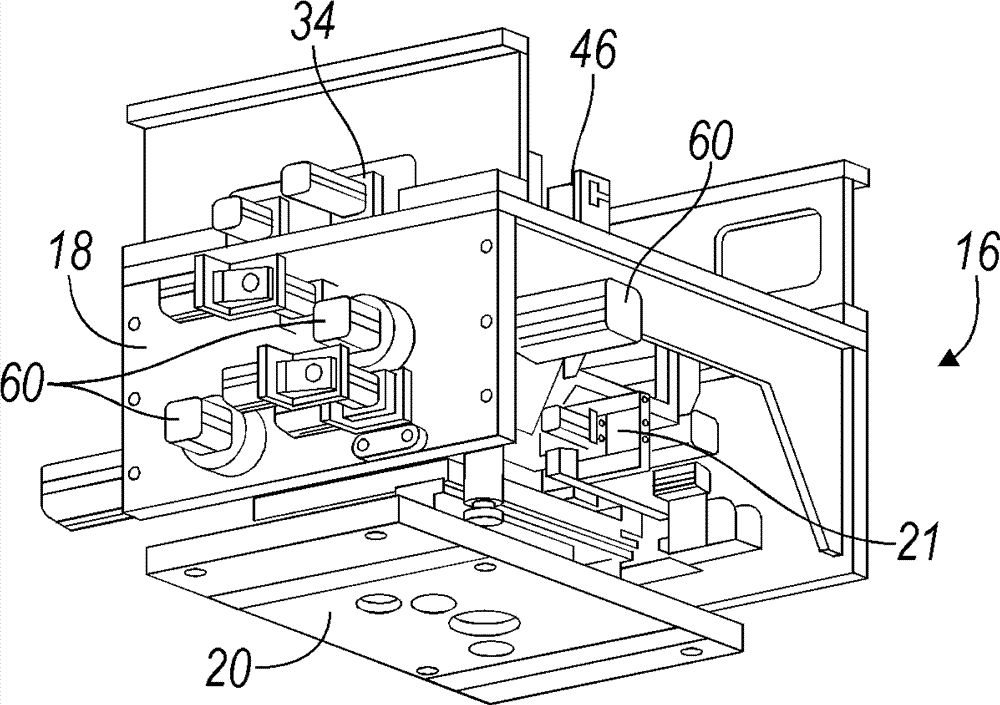

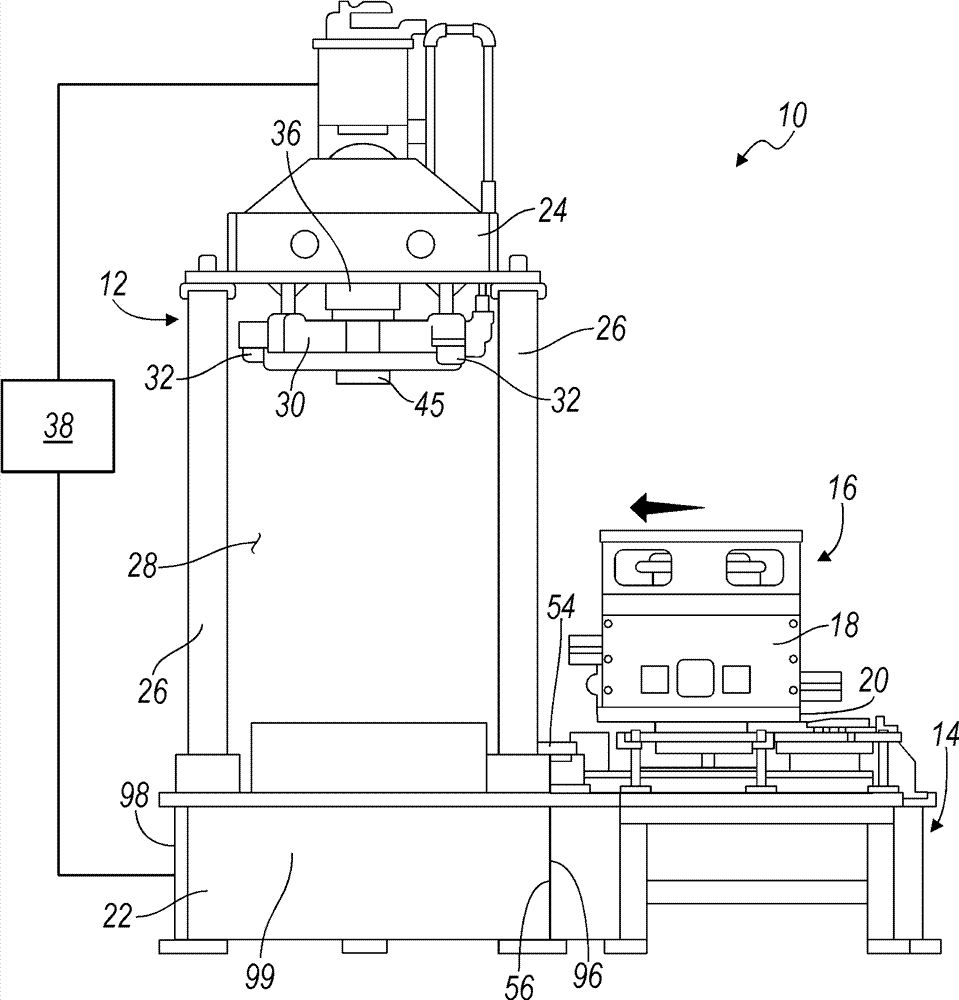

[0070] Referring to the drawings, in which like reference numerals are used to identify like or identical parts throughout the several views, Figure 1 to Figure 2A reconfigurable leak testing system 10 including a leak testing workstation 12 , a transfer shuttle 14 and one or more leak testing fixture decks 16 is shown. Each clamp receptacle 16 may include a respective upper clamp 18 and lower clamp 20 . In addition, each clamp bay 16 is independently translatable along the transfer shuttle 14, as will be further described below.

[0071] image 3 The leak testing system 10 is also shown, but only the lower clamp 20 of the clamp deck 16 is shown so as not to block the view of further details of the leak testing system 10 . Figure 4 The entire clip holder 16 is shown with the part 21 disposed therein. Such as figure 2 As shown, once jig deck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com