Laminated rubber bearing void pre-warning device

A technology of plate-type rubber bearings and early warning devices, which is applied to measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of incomplete detection of bearings, difficulty in detection, failure of bearing early warning, etc., to achieve The effect of improving detection efficiency and accuracy, reducing detection risk, and reducing detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in combination with specific embodiments.

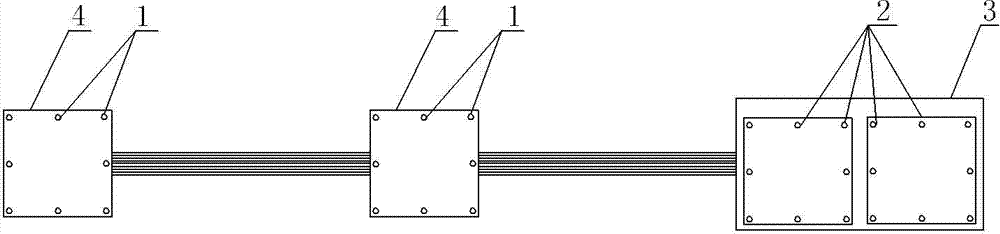

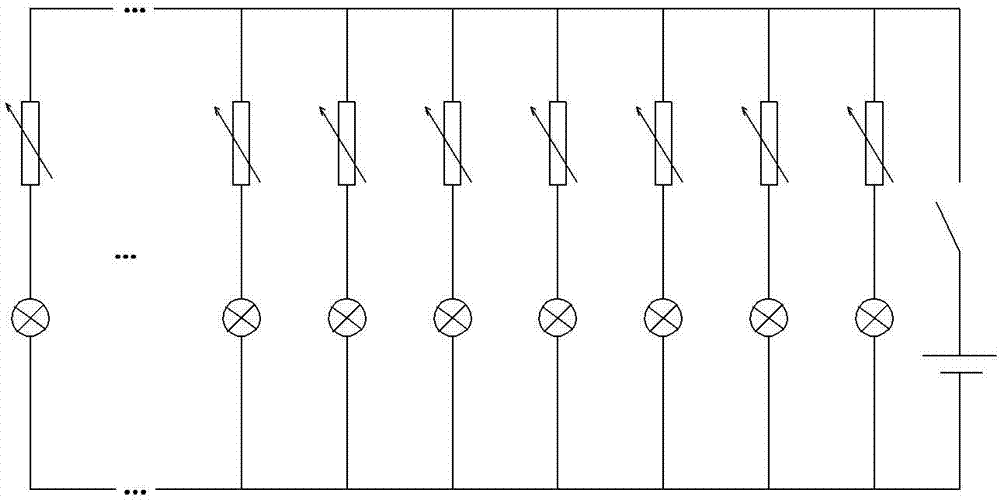

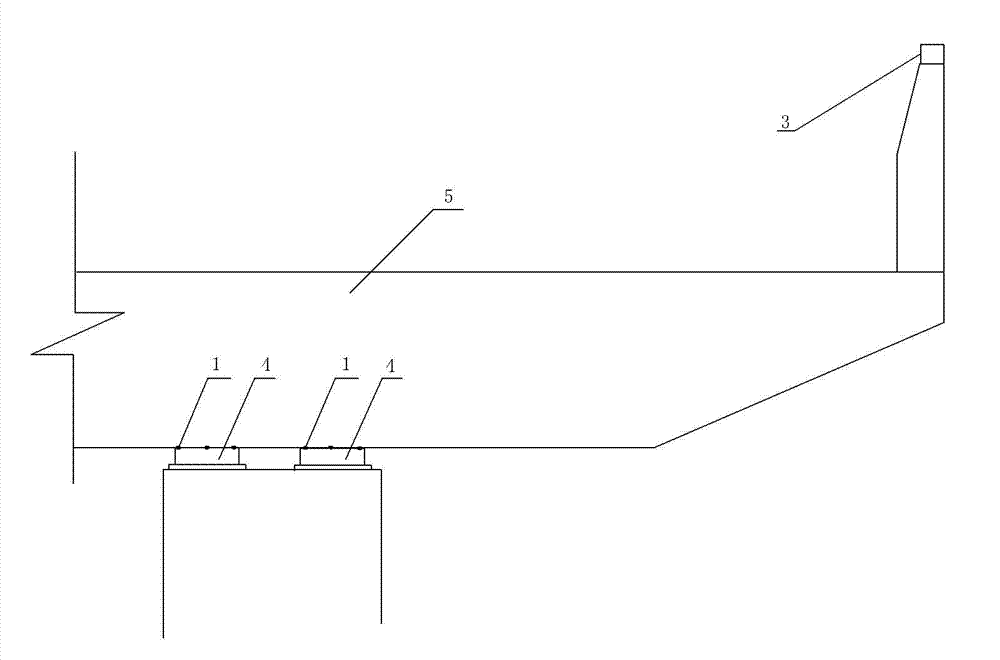

[0018] see figure 1 and image 3 , the present invention relates to a kind of early warning device for plate-type rubber bearings, in which a pressure sensor 1 is set between the top surface of the plate-type rubber bearing 4 and the upper beam body 5 (the model can choose PTS200S sputtering film pressure core or LG-062 etc.), the pressure sensor 1 is connected in series with the warning light 2, the warning light 2 is set on the early warning display 3, and the early warning display 3 is hung on the side of the beam body 5. The pressure sensor 1 is a sheet-type pressure sensor. see figure 1 and figure 2 , the pressure sensor 1 in the early warning device is provided with a plurality of, is arranged at the edge of the four sides of the top surface of the plate rubber bearing 4, each side is provided with 3, a total of 8 pressure sensors 1, each pressure sensor 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com