Dynamic measurement device for shield tunnel lining segment joint wrong lifting

A technology for lining segment and dynamic measurement, which is applied to measurement devices, electrical devices, instruments, etc., can solve the problems of high subjectivity, high cost, and large workload, and achieves strong anti-environmental interference, long working life, and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

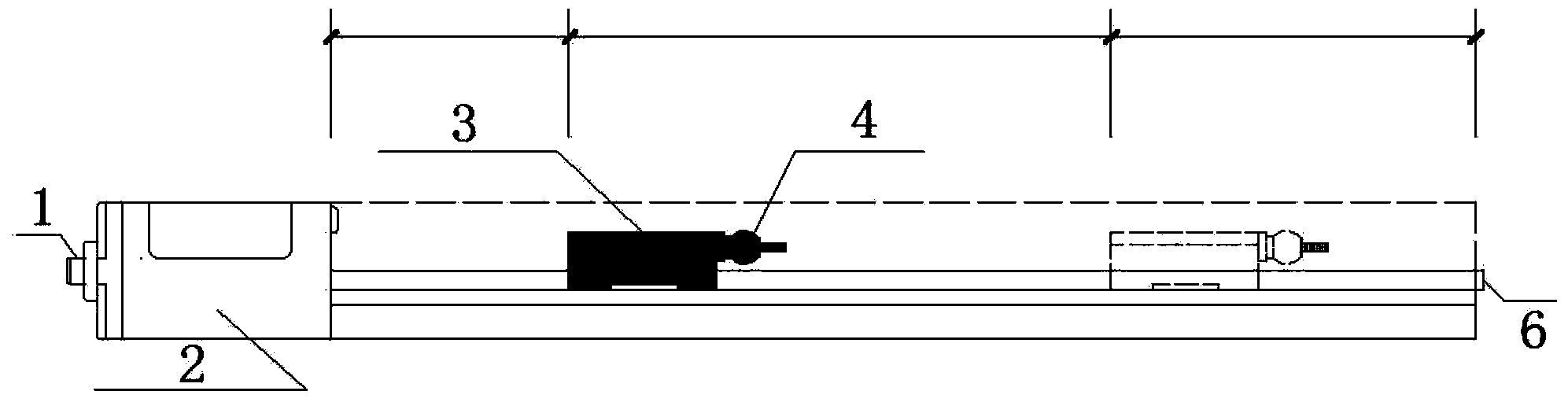

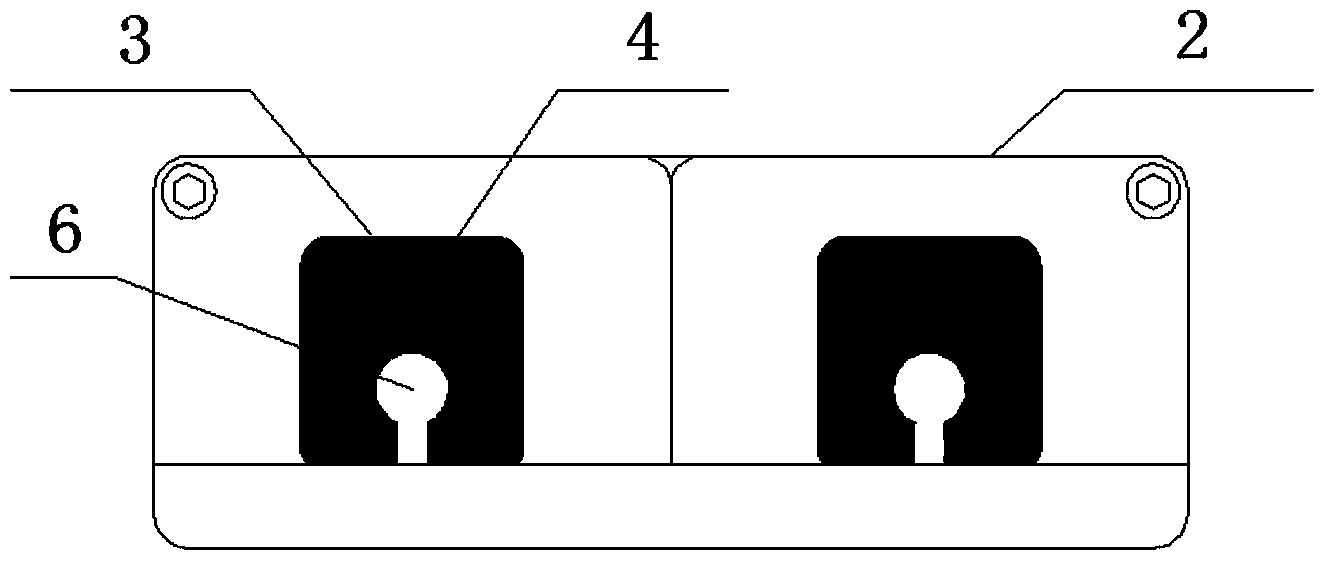

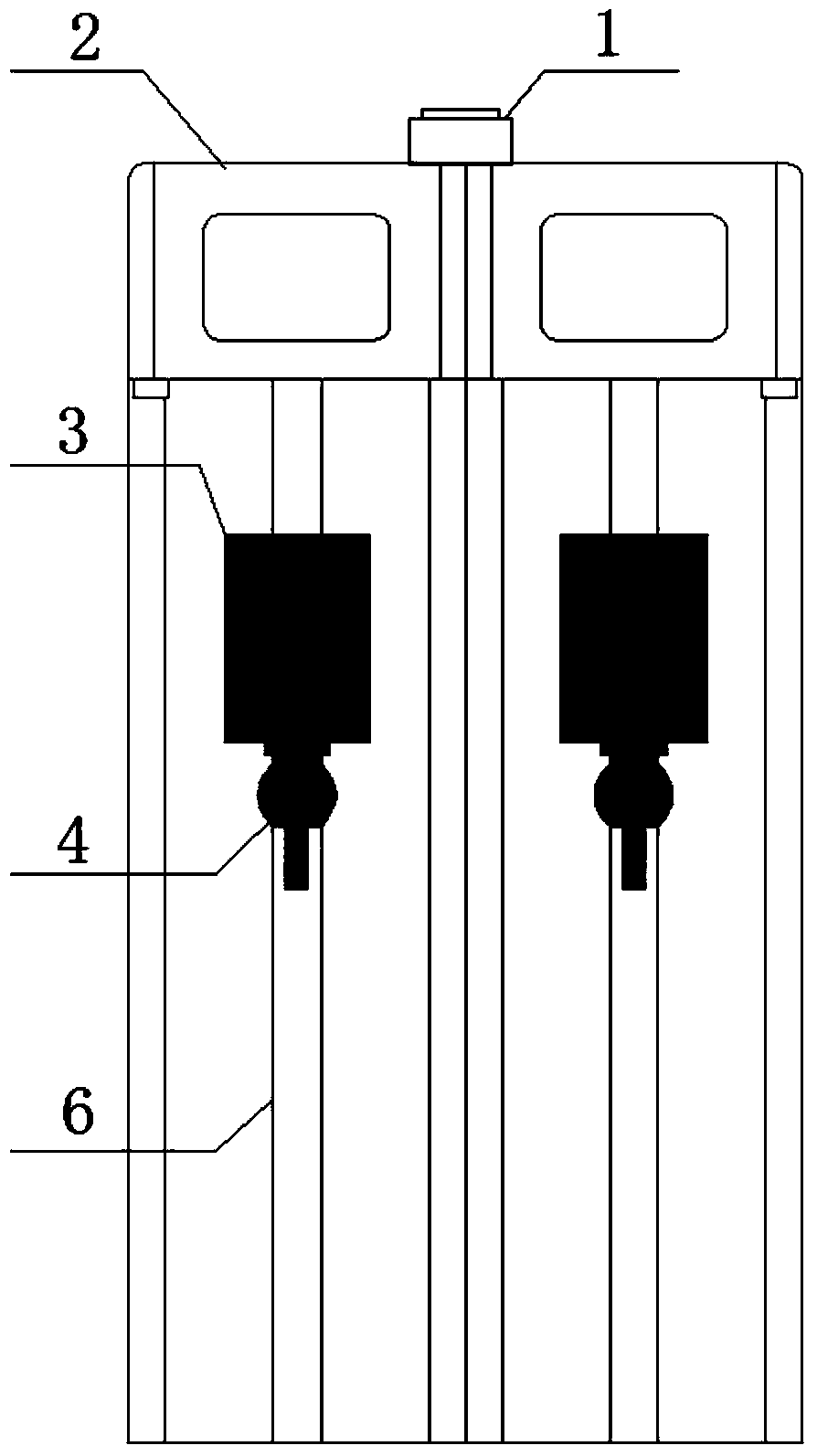

[0029] Such as Figure 1 to Figure 4 As shown in the figure, a dynamic measurement device for the joint lift of shield tunnel lining segments includes an electrical connector terminal 1 for connecting cables to provide electricity, an electronic warehouse module 2 for data processing, two internal A waveguide 6 containing a waveguide wire (the material of the waveguide wire is ferromagnetic or ferrimagnetic material), two sets of slider modules 3 respectively installed on the two waveguides and sliding along the waveguide, and two sets of sliders Two sets of measuring rod modules connected separately by the modules. Wherein, each group of measuring rod modules includes measuring rod 5 and a sliding mechanism located at the end of measuring rod 5 away from the direction of waveguide 6, and each group of slider module 3 includes a slider, a posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com