Thermal protection method for scramjet engine fuel injection supporting plate by utilization of transpiration cooling

A technology of injection support plate and fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

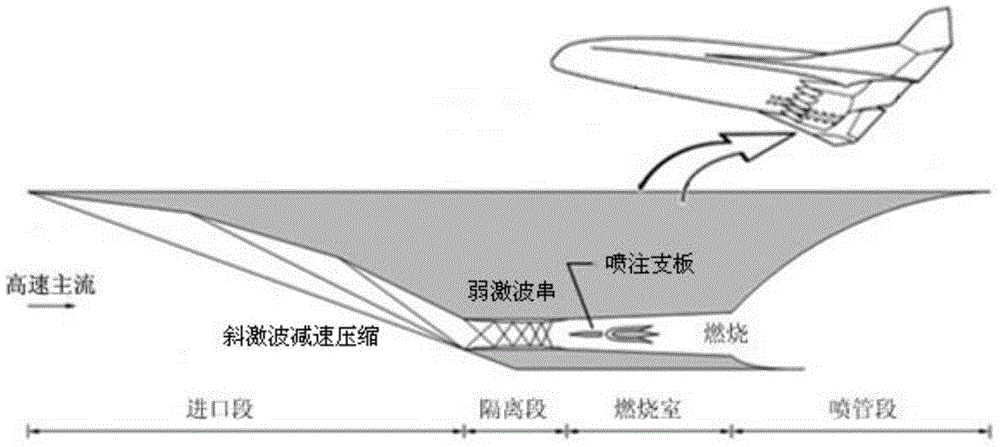

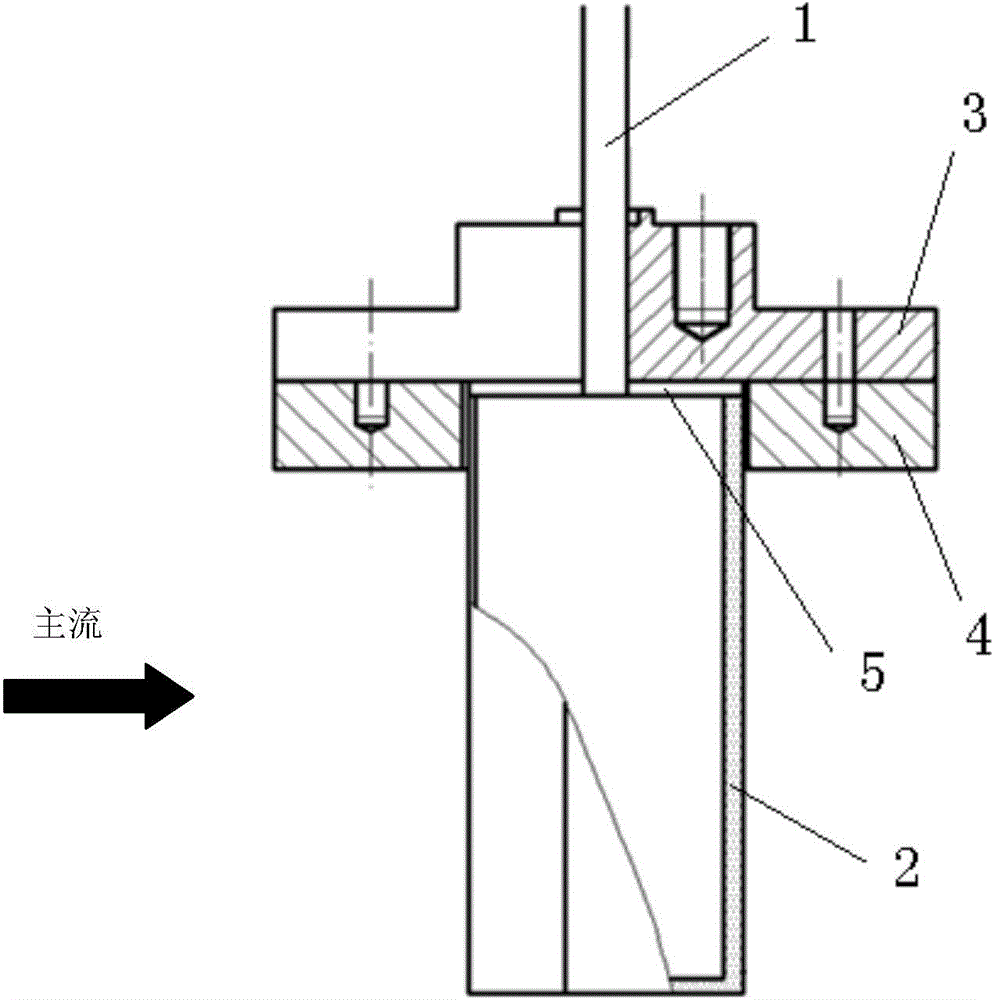

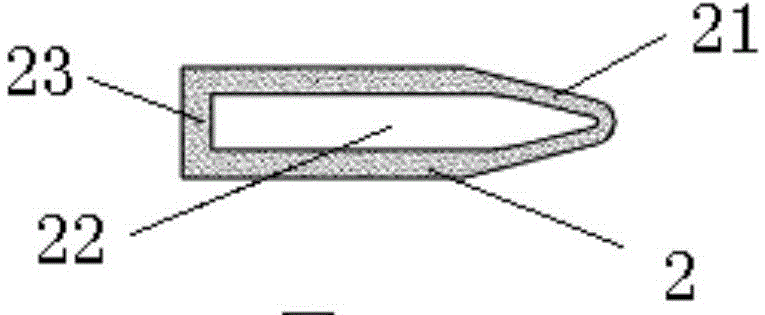

[0021] like figure 1 , figure 2 As shown, in a scram engine, aviation kerosene or liquid hydrogen is generally selected as fuel according to different flight Mach number ranges of the aircraft, and gaseous fuel is also used in some special working environments. The fuel is controlled by the pump carried by the super-combustion generator itself and the valve set on the fuel channel. After reaching a certain pressure, it enters the injection branch plate 2 through a fuel pipe 1, and flows from the injection branch plate 2 according to the design requirements. It is sprayed out from the set oil injection hole, mixed with the mainstream of high-temperature and high-speed airflow, and then burned to provide power. The structure of the method of the present invention is basically the same as that of the prior art, and the difference is that the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com