Six-gear automobile transmission

A technology for automotive transmissions and transmissions, which is applied to vehicle gearboxes, vehicle components, gear transmissions, etc., can solve the problems of no forced lubrication and forced cooling, and achieve superior performance, beautiful appearance, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

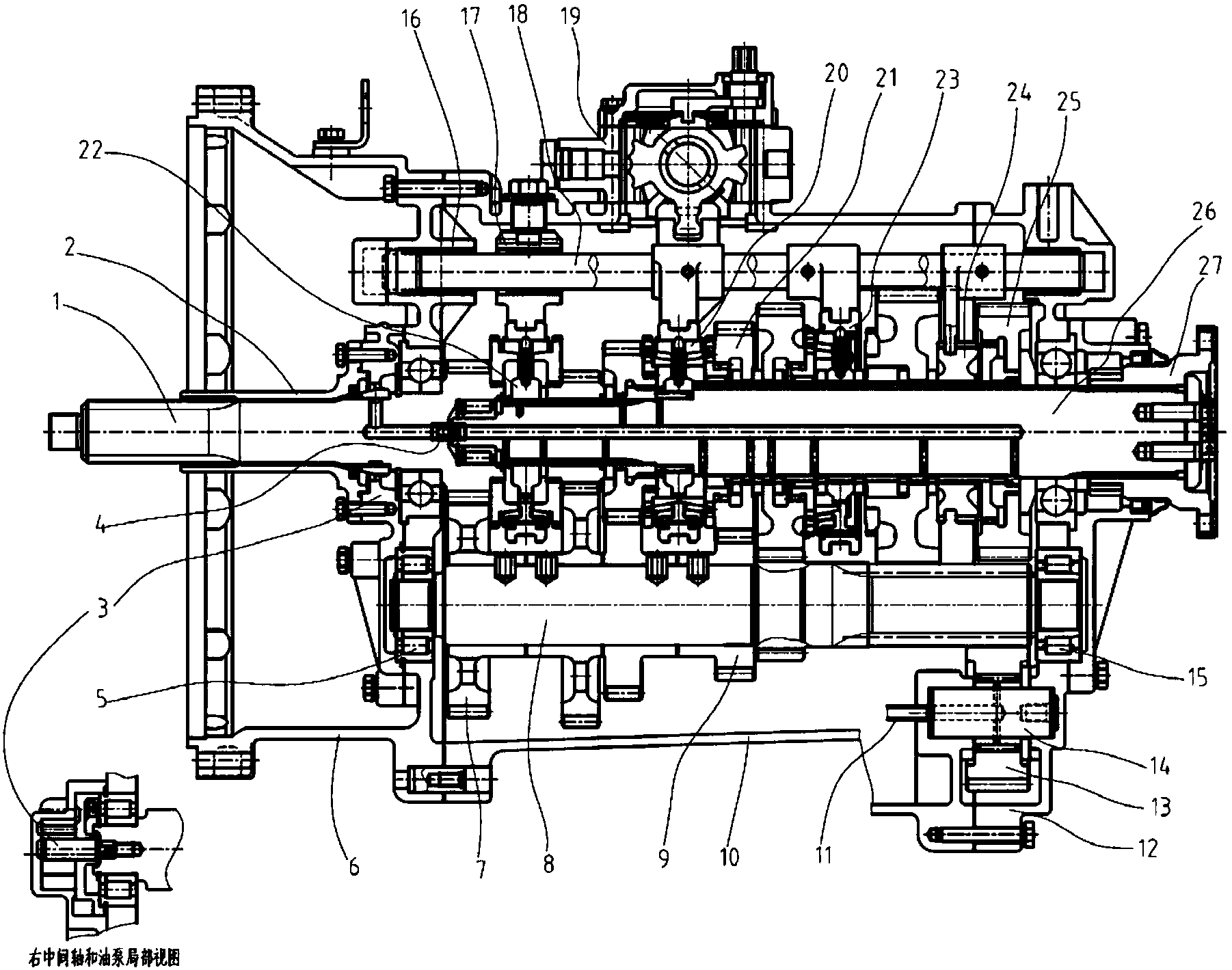

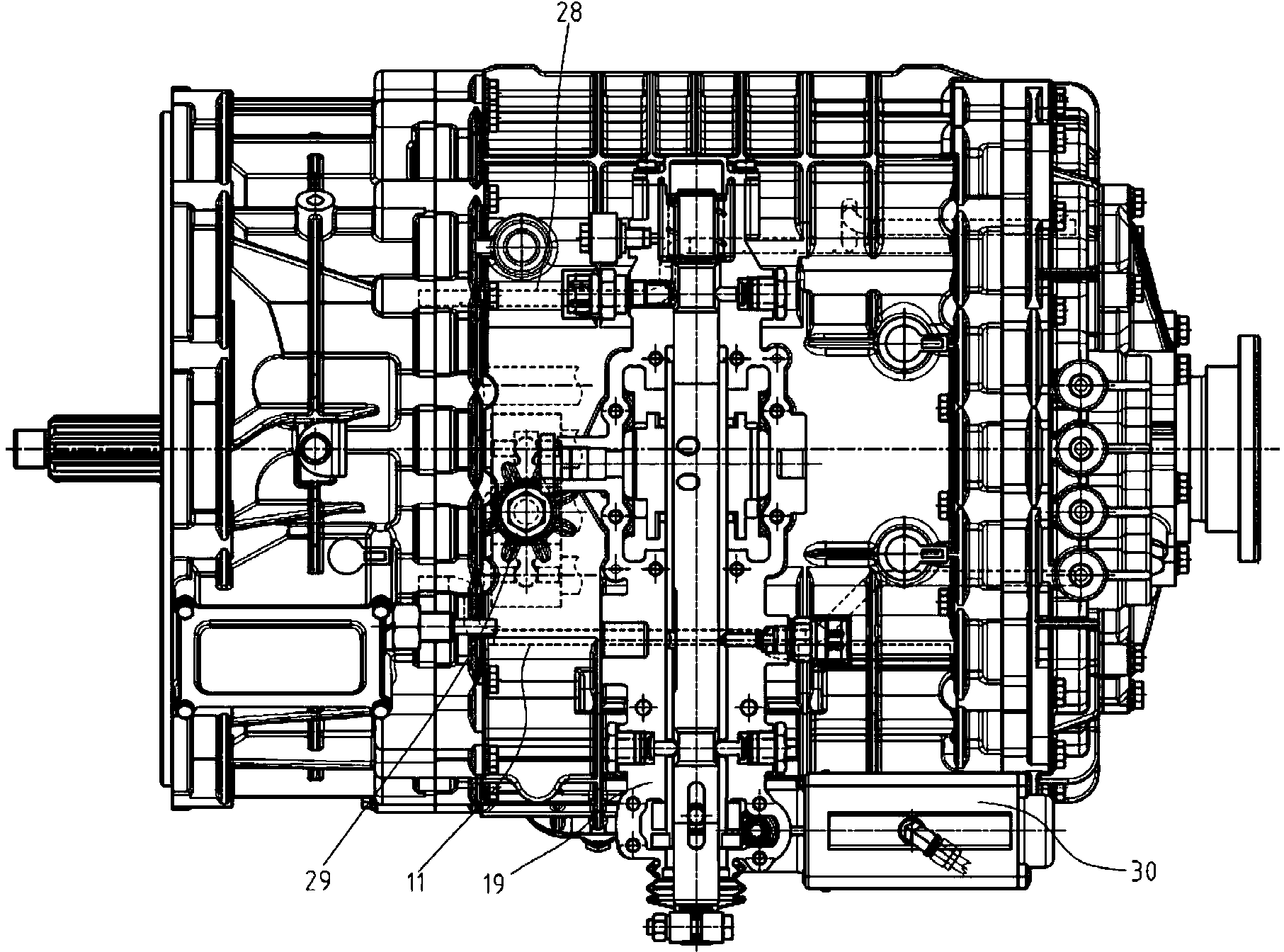

[0025] see figure 1 , figure 2 , the present invention proposes a six-speed automobile transmission, including a box body and an operating mechanism. The box body includes a first shaft 1 and a second shaft 26 connected in sequence, and an intermediate shaft 8 located on both sides of the second shaft 26 and adapted to the second shaft 26. One shaft 1 is provided with a shaft gear, and the second shaft 26 is provided with a first gear, a second gear, a third gear, a fourth gear, a fifth gear, and a reverse gear 25; Axle 8 is two, and transmission gear 7 and five drive gears are all arranged on two intermediate shafts, and transmission gear 7 is constantly meshed with a shaft gear, and five drive gears are the first drive gear, the second drive gear, the second drive gear, and the first drive gear. The third driving gear, the fourth driving gear, and the fifth driving gear are respectively connected with the first gear, the second gear, the third gear, the fourth gear, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com