Novel power end of three-cylinder tailing filling pulp pump

A mud pump and power end technology, which is applied in the field of improvement of the triple-cylinder tailings filling mud pump, can solve the problems of long support span, short design life of the body, poor meshing of transmission gears, etc.

Inactive Publication Date: 2014-03-26

宝鸡航天动力泵业有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

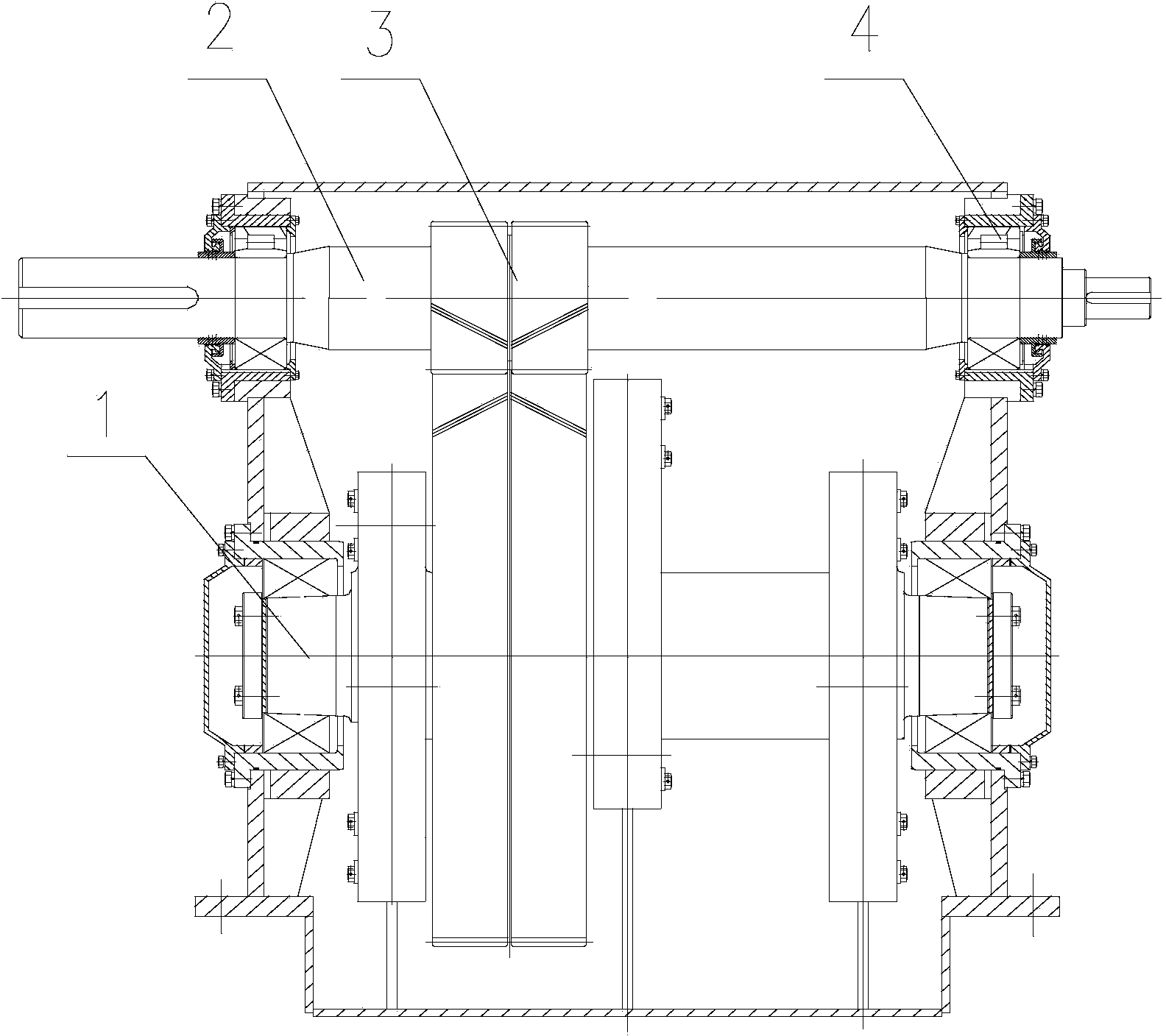

[0005]The traditional structural design is attachedFigure 1, the No. 2 high-speed shaft shown in the picture is supported at both ends by the No. 4 bearing shown in the picture, which is as wide as the frame, and the whole high-speed shaft crosses the frame. The No. 3 person in the picture The word gears are arranged at the position of the two cylinders, so it can be seen that the support points of the two bearings have a relatively long span, and the requirements for the rigidity of the No. To achieve this goal, in addition to the necessary reinforcement during design, the geometric dimensions of these two parts can only be increased, resulting in an increase in the overall size of the body, a long support span, poor meshing of the transmission gears, and large transmission noise. short design life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

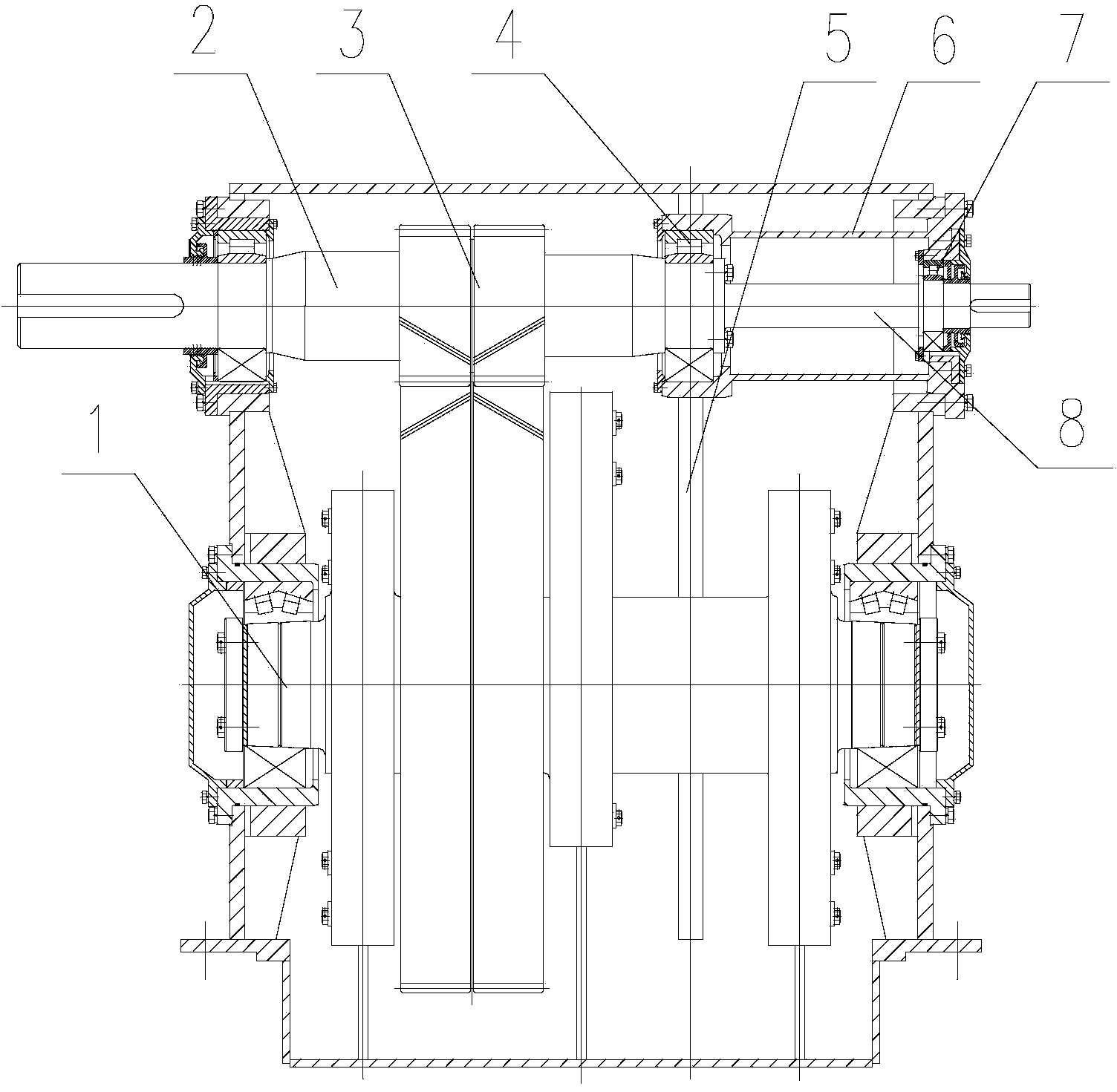

The invention belongs to a novel power end of a three-cylinder tailing filling pulp pump in fluid conveying equipment. The novel power end comprises a low-speed crankshaft and a high-speed half shaft, wherein power is transmitted between the low-speed crankshaft and the high-speed half shaft through a herringbone transmission gear; the high-speed half shaft does not penetrate through a stander; one end of the high-speed half shaft is arranged on one side of the stander through a high-speed bearing, and the other end of the high-speed half shaft is arranged on a supporting ribbed plate through another high-speed bearing; the supporting ribbed plate is fixed in a pump cavity. The novel power end of the three-cylinder tailing filling pulp pump, which is disclosed by the invention, is designed to improve the rigidity and the stability of a high-speed transmission shaft; a long shaft penetrating through the stander is replaced by the half shaft; the supporting ribbed plate is additionally arranged in the pump cavity to fix parts, such as the bearings, of the high-speed transmission shaft; the pivot distance of the transmission gear is shortened, and the bearing capacity under the same shaft neck is greatly improved; meanwhile, due to the additional arrangement of the supporting ribbed plate, the rigidity and the bearing capacity of the whole stander are improved by almost 1 / 3.

Description

technical field [0001] The invention belongs to the technical field of fluid delivery and equipment, in particular to the improvement of a three-cylinder tailings filling mud pump. Background technique [0002] From the 1940s to the early 1950s, foreign countries began to use the graded tailings of the dressing plant for hydraulic filling. In this filling process, there is an excessive amount of -20 μm fine mud, which remains on the surface of the stope filling layer, making mining difficult and unable to form a stable and self-supporting side wall. After entering the 1960s, countries such as the United States, Canada, Australia, Germany, the former Soviet Union and my country have developed new preparation and transportation equipment for filling slurry, coupled with the application of trackless mining equipment, the cemented filling process has made great progress. Advances have changed the face of fill mining. However, since the actual mass concentration of the slurry us...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04C2/16F04C15/00

Inventor 郑宏乾唐春玲王雨团

Owner 宝鸡航天动力泵业有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com