Drill core direction recovery method

A recovery method and core technology, applied in the field of high-level radioactive waste geological disposal research, can solve the problems of incomplete splicing of drilled cores, inability to determine the exact orientation of structural planes of deep drilled cores, loss of valuable information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following structural drawings and implementation examples further illustrate the method for restoring the orientation of a drilled rock mass provided by the present invention.

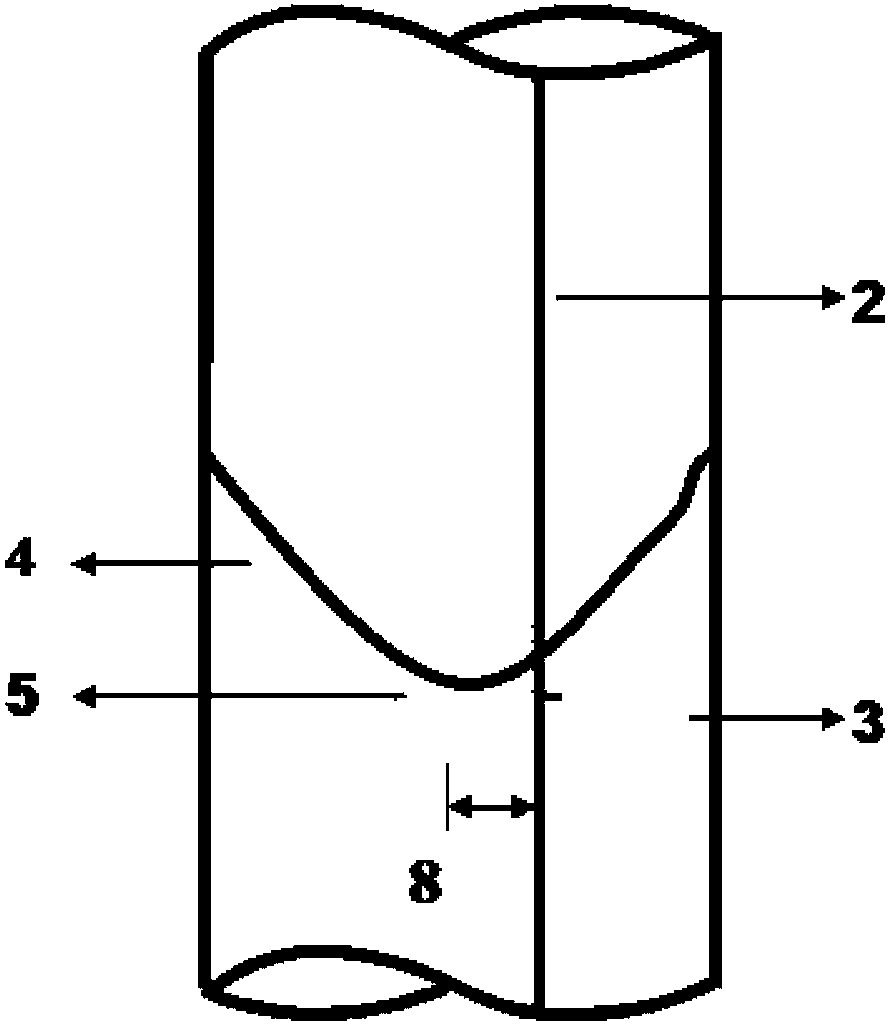

[0023] A drilling core orientation recovery method, such as figure 1 shown, including the following steps:

[0024] (1) Core baseline delineation: if figure 2 As shown, the core 1 is connected in order from top to bottom in the direction close to the surface; the baseline 2 is delineated in the complete splicing section of each core, and the depth mark 3 is marked; when the baseline 2 is delineated, it should be ensured that The cores within the same baseline range are seamlessly spliced to ensure that the relative orientations of each structural plane and the baseline are accurate. This baseline ends and is flagged for cases where the core cannot be spliced due to chipping or breakage. A new baseline is marked on the next complete segment of the core. When delineating the baseline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com