Medium- and shallow-gas well drainage technique pipe and drainage method

A technology of process pipe string and shallow gas, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of bottom hole liquid accumulation, and achieve the effect of simple construction equipment, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

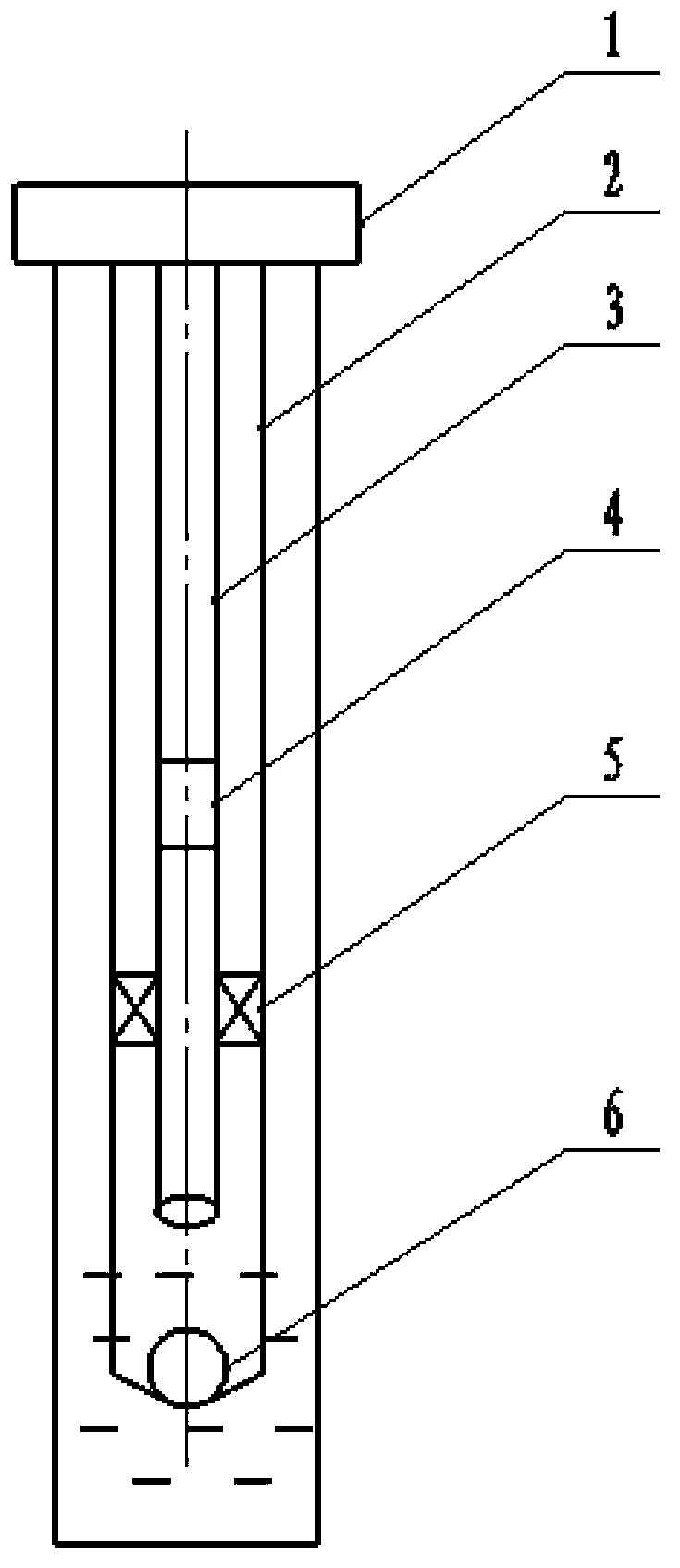

[0014] In the present invention, the shallow gas well drainage process pipe string and the drainage method mainly solve the problem of bottom hole accumulation in gas wells within 2000 meters.

[0015] So figure 1 As shown, first, insert the oil pipe 2, into the combined pipe string of the sealed packer 5 and the dedicated bottom valve 6 at the entrance hole position or below the perforation position, and then lower the small diameter oil pipe 3 and the hydraulic jet pump 4 assembly The oil pipe 2 is inserted in the middle of the sealed packer 5, and the hydraulic jet pump 4 is lowered to a predetermined depth according to the design requirements. Thereby establishing three channels.

[0016] Secondly, the ground pump 1 is used to power the hydraulic jet pump 4.

[0017] Finally, the surface pump 1 uses the high-pressure power fluid to drive the hydraulic jet pump 4 to gradually discharge the liquid above the dedicated bottom valve 6, causing the pressure above the dedicated bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com