Single-shutter type steel composite thermal-insulation fire-resistance rolling shutter door

A rolling shutter door and steel technology, applied in the field of rolling shutter doors, can solve problems such as inconvenient design and installation, waste of water resources, large water consumption, etc., to improve fire resistance and heat insulation, improve heat insulation and strength, and save water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

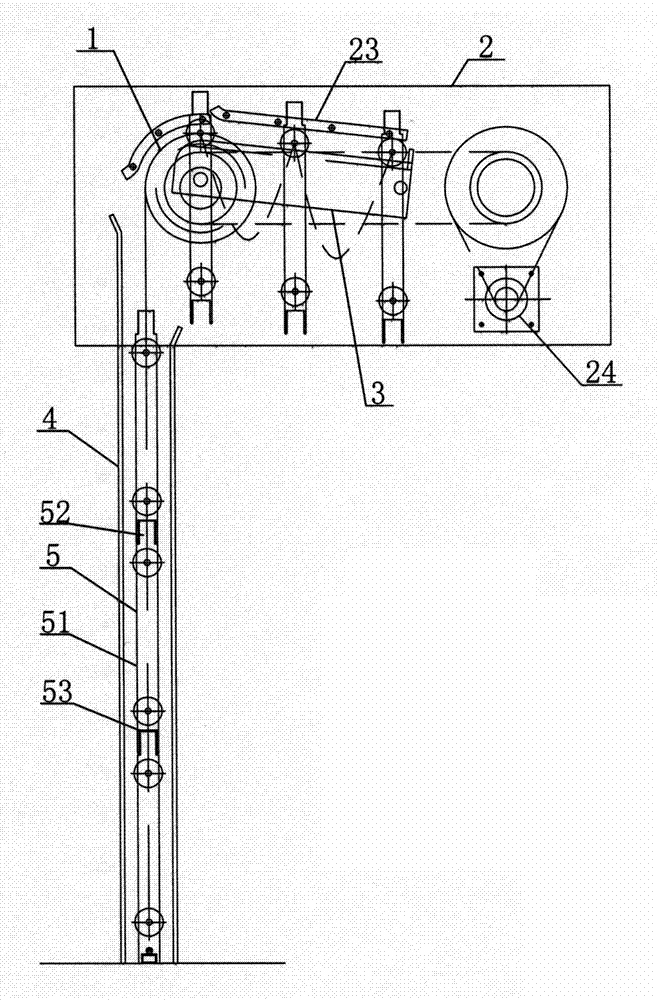

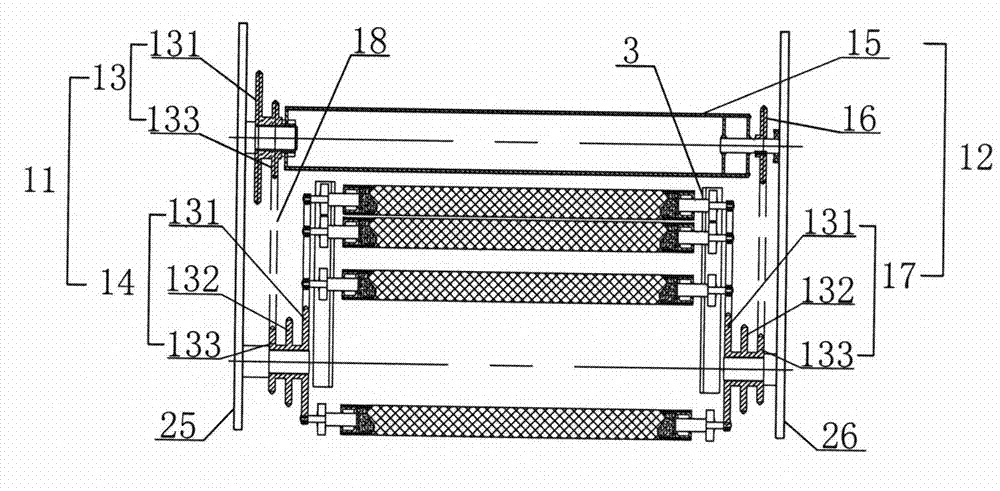

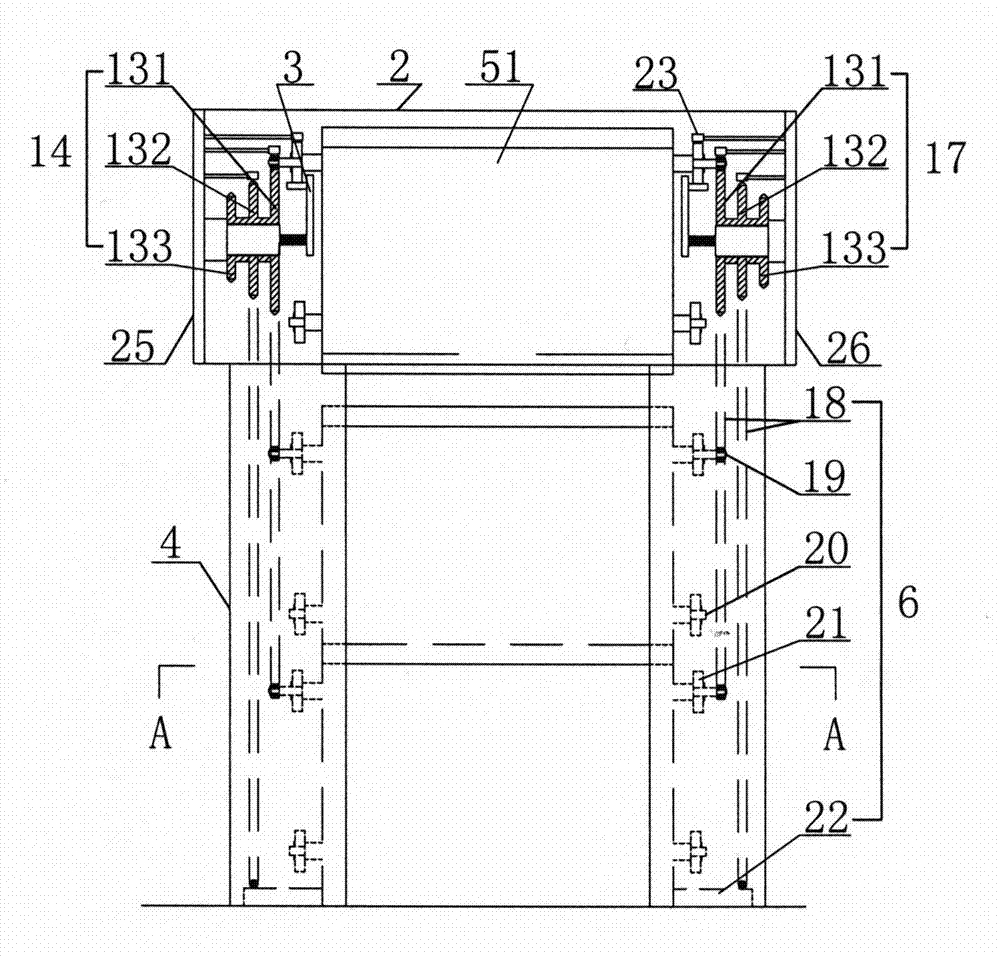

[0032] Such as figure 1 , figure 2 and image 3 Shown, the structural representation of the present invention, it comprises transmission mechanism 1, bag case 2, slideway 3, guide rail 4 and roller shutter 5, and transmission mechanism 1 comprises main transmission mechanism 11 and auxiliary transmission mechanism 12, main transmission mechanism 11 and auxiliary transmission mechanism The transmission mechanism 12 is installed in the bag case 2 respectively, and a slideway 3 is fixed between the main transmission mechanism 11 and the auxiliary transmission mechanism 12. The slideway 3 and the transmission mechanism 1 are longitudinally parallel in the bag case 2, and the slideway 3 is The front end is high and the rear end is low, and the guide rail 4 is vertically installed below the main support plate 25 and the auxiliary support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com