Decorative sheet and decorative material using same

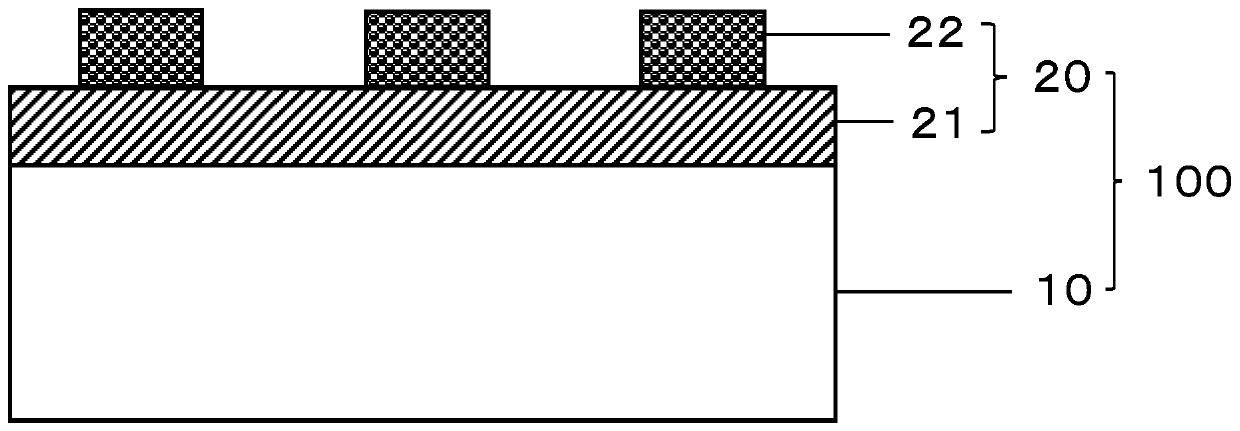

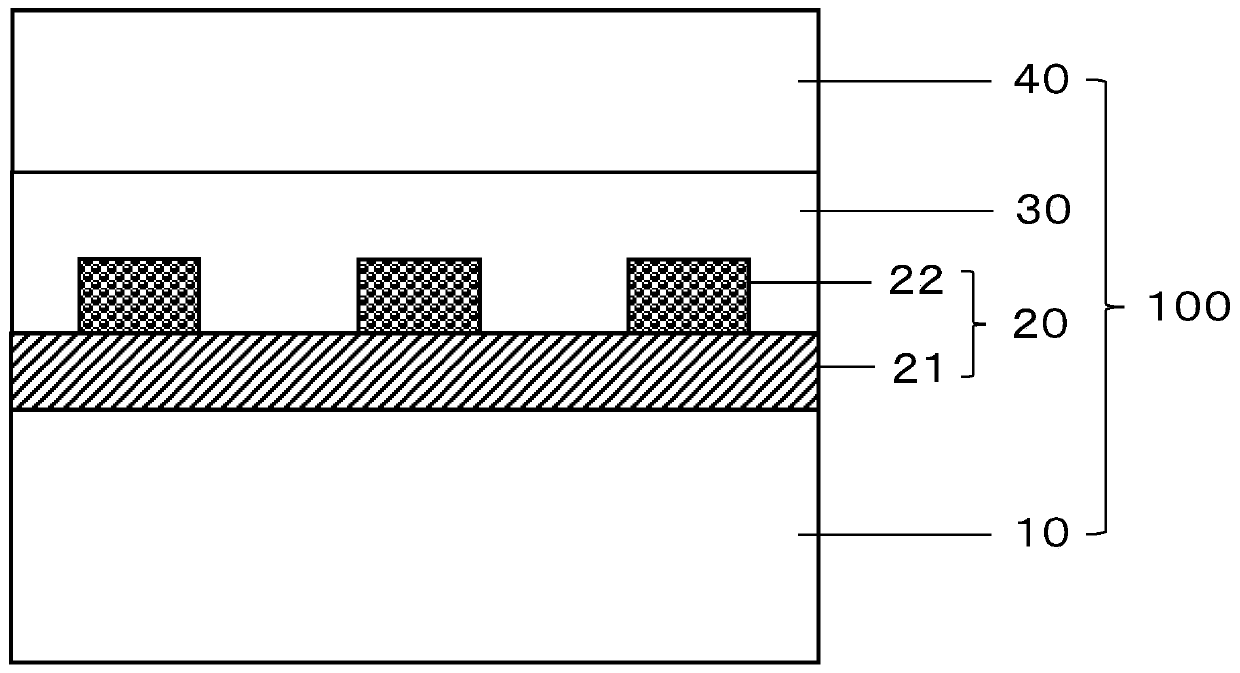

A decorative sheet and decorative layer technology, which can be applied to decorations, decorative arts, special decorative structures, etc., and can solve the problems of peeling off the adherend from the decorative sheet, deformation of the decorative material, and insufficient thermal insulation of the decorative sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

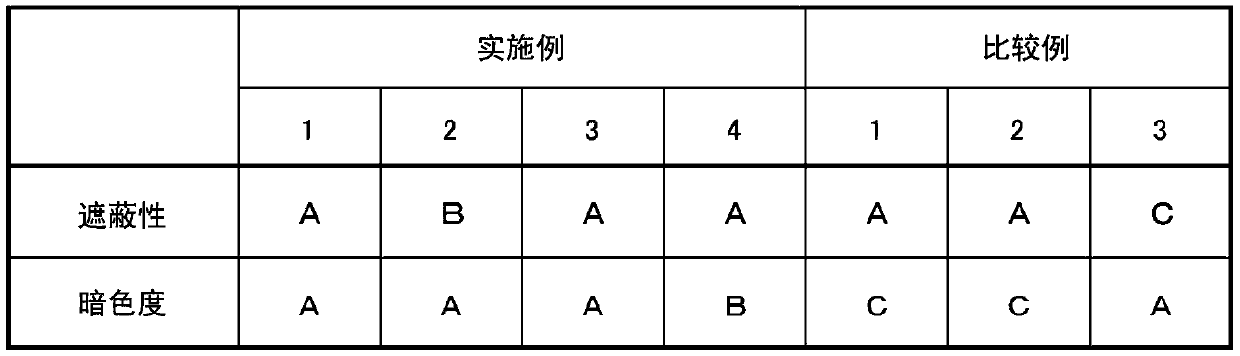

Embodiment 1

[0200] As a base material having infrared reflectivity, prepare a base material (60 μm in thickness) comprising a manganese-based composite oxide. The average value of the spectral reflectance at a wavelength of 780 to 2500 nm is 35%, L *value: 58), on one side of the sheet, the solid printing layer forming ink 1 of the following formulation was applied by the gravure coating method, and dried to form a solid printing layer (bark pattern) with a thickness of 4 μm. ).

[0201]

[0202] · Binder resin (acrylic urethane resin) 76 parts by mass

[0203] 10 parts by mass of red pigment (C.I. Pigment Red 122)

[0204] (average particle size: 0.13μm)

[0205] 9 parts by mass of yellow pigment (C.I. Pigment Yellow 150)

[0206] (average particle size: 0.05μm)

[0207] 5 parts by mass of blue pigment (C.I. Pigment Blue 15)

[0208] (average particle size: 0.04μm)

[0209] ·Appropriate amount of diluting solvent

[0210] Next, on the solid printing layer, the pattern layer form...

Embodiment 2

[0230] The decorative sheet and decorative material of Example 2 were obtained in the same manner as in Example 1 except that the ink 1 for forming a solid printing layer was changed to the ink 2 for forming a solid printing layer of the following formulation.

[0231]

[0232] · Binder resin (acrylic urethane resin) 30 parts by mass

[0233] · Infrared reflective pigments (TiO 2 ) 50 parts by mass

[0234] · 9 parts by mass of infrared transmissive pigment (FeOOH)

[0235] (average particle size: 0.1μm)

[0236] ・Infrared transmissive pigments (Fe 2 o 3 ) 6 parts by mass

[0237] (average particle size: 0.1μm)

[0238] 5 parts by mass of infrared reflective pigment

[0239] (Composite oxides containing manganese, calcium and titanium as metal elements)

[0240] (Ishihara Sangyo Co., Ltd., model: MPT-370, black pigment, average primary particle size 0.8 μm)

[0241] ·Appropriate amount of diluting solvent

Embodiment 3

[0243] Change the base material having infrared reflectivity into a base material (60 μm in thickness) comprising titanium oxide. The average value of the spectral reflectance coefficient of wavelength 780-2500 nm is 40%, L * Value: 90), except that the ink 1 for forming a solid printing layer was changed to the ink 2 for forming a solid printing layer of the above formulation, and the decorative sheet and the decorative material of Example 3 were obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com